Preparation method of reversed polarity AlGaInP quaternary LED chip

A LED chip and reverse polarity technology, which is applied in the field of optoelectronics, can solve the problems of complex process, high cost, and low yield rate, and achieve the effect of simplifying the bonding process, simple process, and improving product yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A method for preparing a reverse polarity AlGaInP quaternary LED chip, comprising:

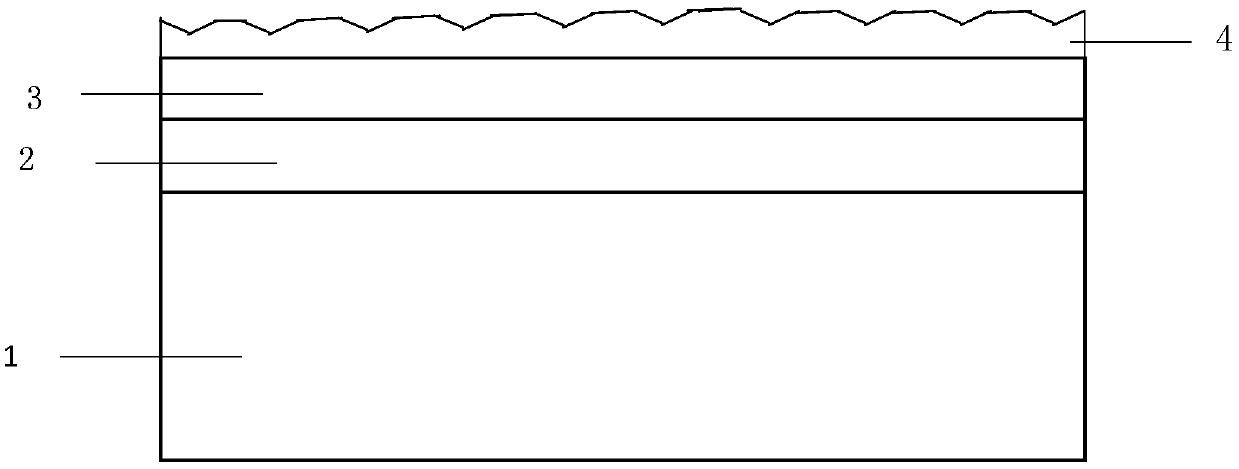

[0071] (1) On the GaAs substrate 1, the heavily doped N-type layer 2 and the quantum well layer 3 are grown sequentially, and the P-type layer 4 of the epitaxial wafer is roughened: using a mixed solution of HF, HNO3 and CH3COOH, the volume ratio of each substance is 3:2: 4. The temperature of the corrosive solution is 25-35°C, and the soaking time of the solution is 30-120s. Such as figure 1 shown.

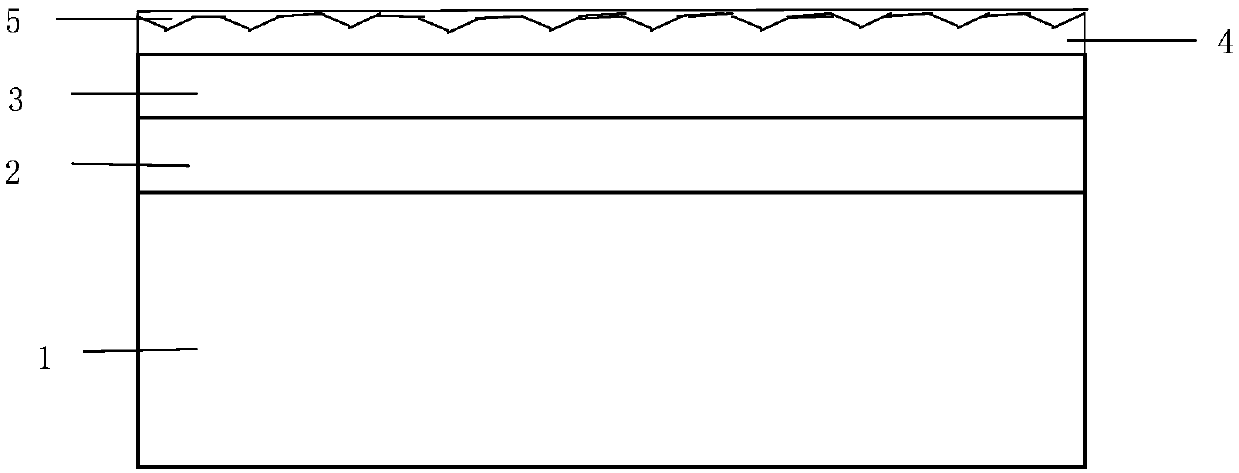

[0072] (2) On the roughened P-type layer 4 surface, prepare ITO film 5, SiO 2 Thin film, ITO thin film 5 thickness SiO 2 membrane thickness Such as figure 2 shown.

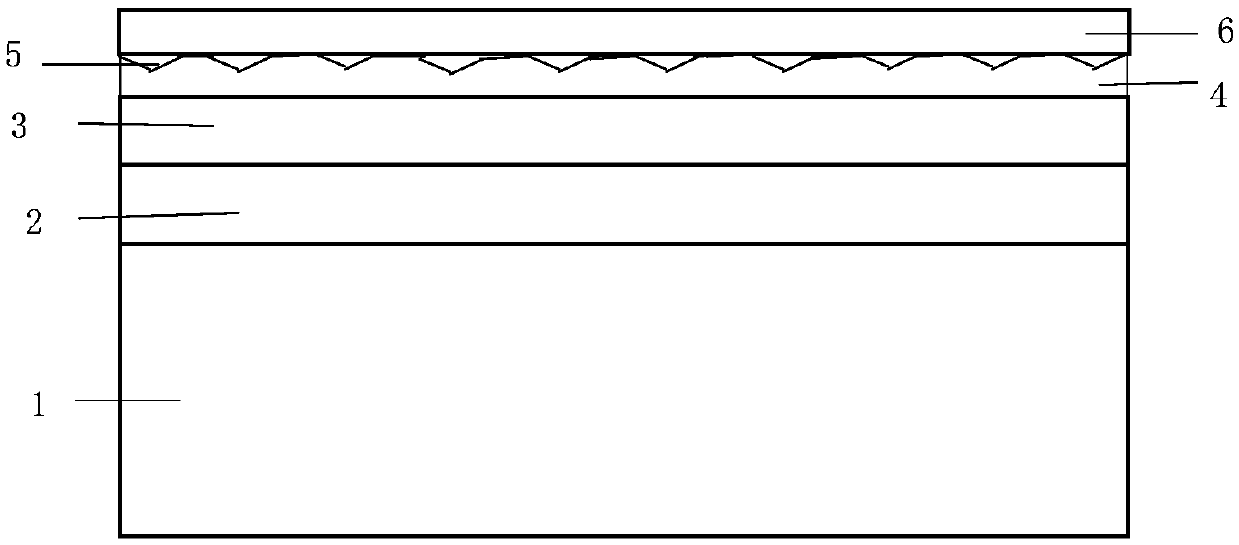

[0073] (3) Mix low-temperature glass powder and high-purity water into a paste, and apply it to the surface of the P-type layer 4 formed in step (2). The thickness of the glass powder is controlled at 1-2mm, and the furnace tube can be used to heat, and the furnace tube can maintain a low vacuum state, according to ...

Embodiment 2

[0084] A method for preparing a reverse polarity AlGaInP quaternary LED chip, comprising:

[0085] (1) On the GaAs substrate 1, the heavily doped N-type layer 2 and the quantum well layer 3 are sequentially grown, and the P-type layer 4 of the epitaxial wafer is roughened: using a mixed solution of HF, HNO3 and CH3COOH, wherein the volume ratio of each substance is 3:2 :4, the temperature of the corrosive solution is 25-35°C, and the soaking time of the solution is 30-120s.

[0086] (2) On the surface of the roughened P-type layer 4, prepare ITO film, SiO 2 film, where the thickness of the ITO film 5 SiO 2 membrane thickness

[0087] (3) Mix low-temperature glass powder and high-purity water into a paste, and apply it to the surface of the P-type layer 4 formed in step (2). The thickness of the glass powder is controlled at 1-2mm, and the furnace tube can be used to heat, and the furnace tube can maintain a low vacuum state, according to the steps in Table 2 below, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com