A kind of fish meal microbial fermentation and enzymatic hydrolysis method

A technology of microbial fermentation and fish meal, applied in fermentation, animal feed, animal feed and other directions, can solve the problem of low utilization rate of fish meal digestion, and achieve the effect of eliminating specific odor, improving quality and improving digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: process optimization of Bacillus subtilis fermented fish meal

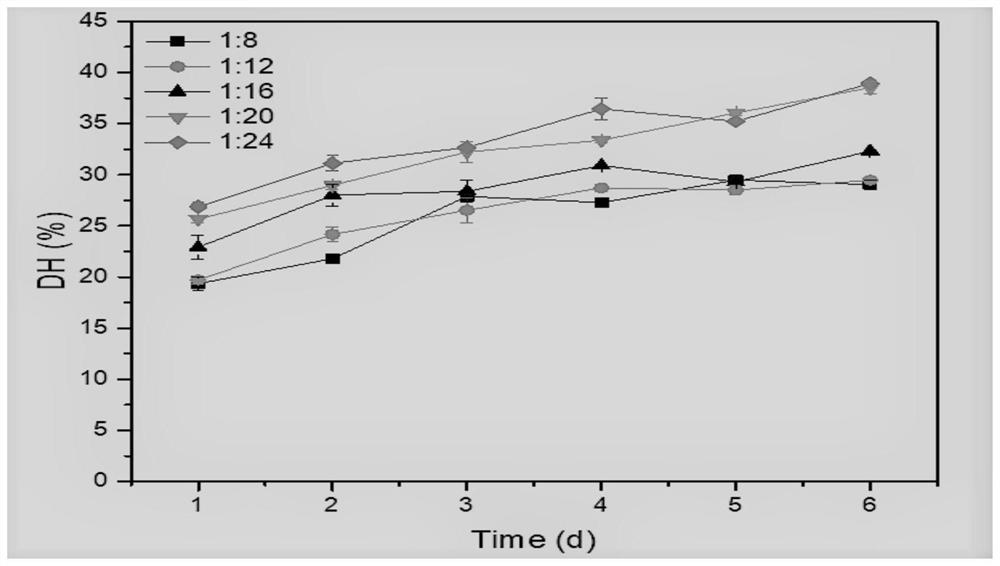

[0047] 1. Optimization of solid-liquid ratio

[0048]After activation of Bacillus subtilis, 10% of the inoculum was inserted into the fishmeal medium with a solid-liquid ratio of 1:24, 1:20, 1:16, 1:12, and 1:8, and the initial pH of the fishmeal medium was adjusted to 6 at 30°C. , cultured at 200rpm, and samples were taken every 24h to determine the degree of hydrolysis, and two parallels were set up in each group. The fermentation broth was centrifuged (8000r / min, 10min) and the supernatant was taken to measure amino nitrogen (formaldehyde titration) and soluble protein (biuret method). Calculation of degree of hydrolysis (DH):

[0049] DH=free amino acid content in hydrolyzate at different times / total amino nitrogen and total protein content in fishmeal medium*100%

[0050] The results are attached figure 1 As shown, the degree of hydrolysis of the solid-liquid ratio 1:24 is the highest...

Embodiment 2

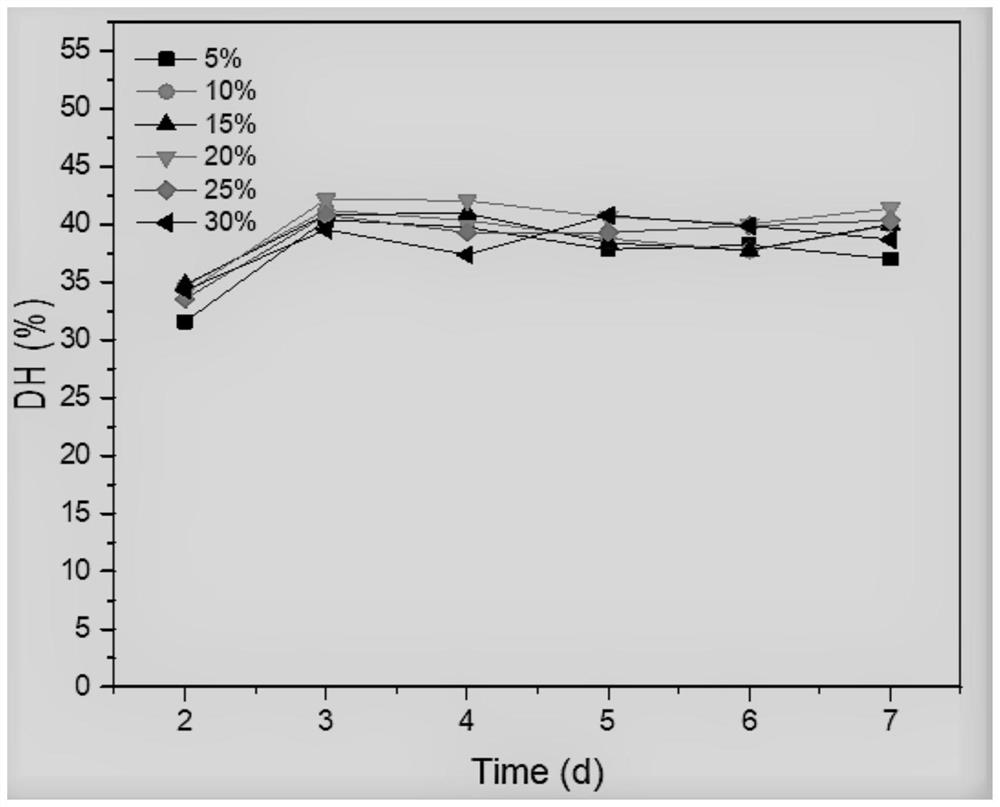

[0060] Embodiment 2: process optimization of bacillus licheniformis fermented fish meal

[0061] 1. Optimization of solid-liquid ratio

[0062] After the activation of Bacillus licheniformis, 5% inoculum was inserted into the fishmeal medium with a solid-liquid ratio of 1:20, 1:16, 1:12, 1:8, and 1:4, and the initial pH of the fishmeal medium was adjusted to 6. Cultivate at 30°C and 200 rpm, take samples every 24 hours to measure the degree of hydrolysis, and set two parallels for each group. The fermentation broth was centrifuged (8000r / min, 10min) and the supernatant was taken to measure amino nitrogen (formaldehyde titration) and soluble protein (biuret method). Calculation of degree of hydrolysis (DH):

[0063] DH=free amino acid content in hydrolyzate at different times / total amino nitrogen and total protein content in fishmeal medium*100%

[0064] The results are attached Figure 5 As shown, the degree of hydrolysis of the solid-liquid ratio 1:12 group reached the hi...

Embodiment 3

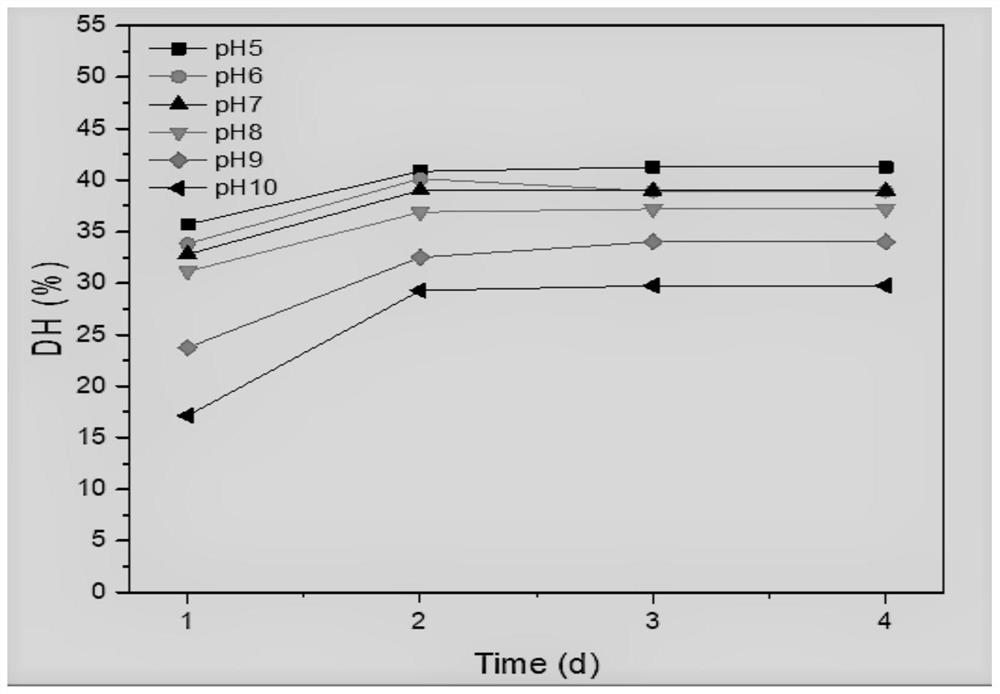

[0074] Embodiment 3: Enzymolysis and mixed fermentation after Bacillus subtilis fermentation

[0075] After activation of Bacillus subtilis, 10% of the inoculum was inserted into the fish meal medium with a solid-liquid ratio of 1:12, and divided into 5 groups. Groups 1-4 were cultured at 30°C and 200rpm for three days, then added papain, neutral Protease, alkaline protease and flavor protease 1000U / mL were reacted at 50°C and 200rpm in a water bath shaker, and samples were taken every hour to determine the degree of hydrolysis; the fifth group was sterilized after three days of fermentation, and 10% Bacillus licheniformis was added to ferment, 24h samples were taken to determine the degree of hydrolysis. There are two parallels for each group. The calculation method of the degree of hydrolysis (DH) refers to the aforementioned "optimization of solid-liquid ratio".

[0076] After testing, the degree of hydrolysis reached 40.68% on the second day of fermentation by the two ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com