A composite water quality treatment material for waste water and sewage

A water quality treatment and composite technology, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as increase in quantity and harm, and achieve removal of impurities, improved adsorption and removal effect, the effect of improving adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A composite water quality treatment material for waste water and sewage, prepared by the following method:

[0029] S1 zeolite pretreatment: Stir the zeolite in hydrochloric acid solution, let it stand, and filter; boil the filtered zeolite in distilled water, wash it with distilled water, and finally put the zeolite in an oven to bake, and cool it for later use ;

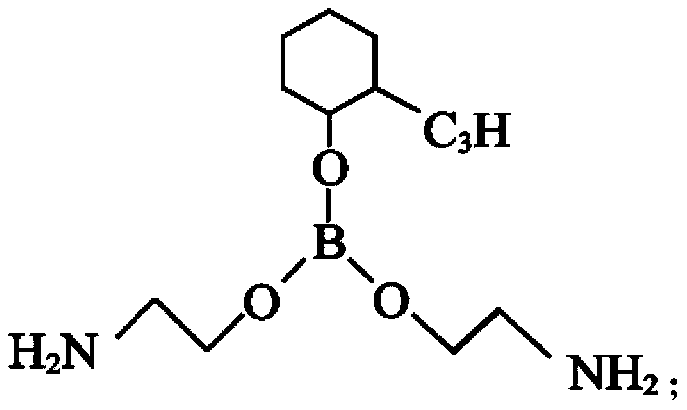

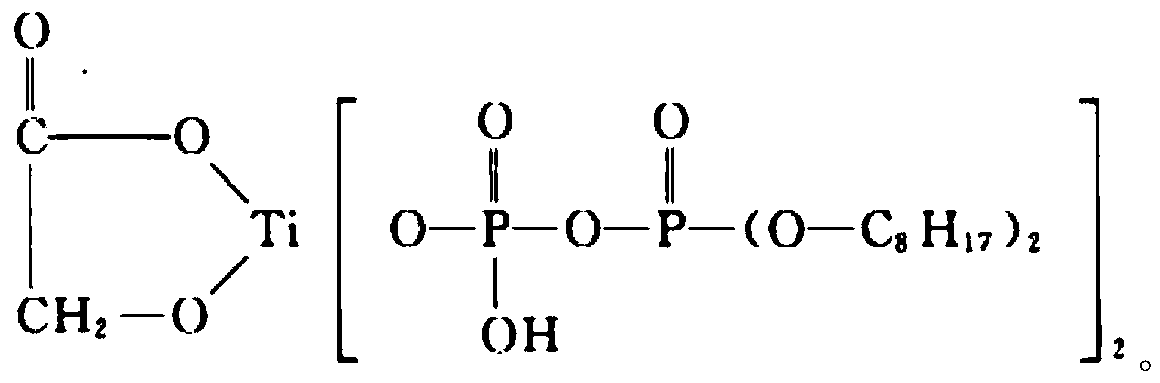

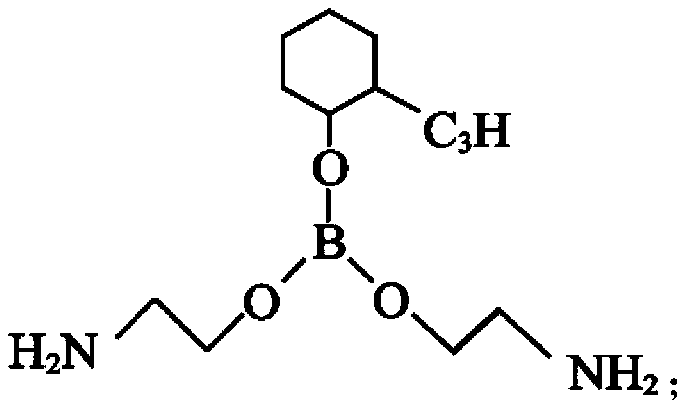

[0030] S2 Preparation of zeolite-supported nano-titanium dioxide: Add 10 g of pretreated zeolite and 5 g of coupling agent to 200 mL of titanium dioxide sol, filter out the sieve after ultrasonication and let it stand, dry it at a constant temperature and roast it under nitrogen protection, and naturally cool down to 100 Stop flowing nitrogen at ℃, wash with distilled water after cooling to room temperature, and dry to obtain zeolite-loaded nano-titanium dioxide; wherein, the titanium dioxide sol can be prepared by the method described in CN104828916B.

[0031] S3 Soak bentonite in sulfuric acid, rinse with...

Embodiment 2

[0041] A composite water quality treatment material for waste water and sewage, prepared by the following method:

[0042] S1 zeolite pretreatment: Stir the zeolite in hydrochloric acid solution, let it stand, and filter; boil the filtered zeolite in distilled water, wash it with distilled water, and finally put the zeolite in an oven to bake, and cool it for later use ;

[0043] S2 Preparation of zeolite-supported nano-titanium dioxide: Add 10 g of pretreated zeolite and 5 g of coupling agent to 200 mL of titanium dioxide sol, filter out the sieve after ultrasonication and let it stand, dry it at a constant temperature and roast it under nitrogen protection, and naturally cool down to 100 Stop flowing nitrogen at ℃, wash with distilled water after cooling to room temperature, and dry to obtain zeolite-loaded nano-titanium dioxide; wherein, the titanium dioxide sol can be prepared by the method described in CN104828916B.

[0044] S3 Soak bentonite in sulfuric acid, rinse with d...

Embodiment 3

[0054] A composite water quality treatment material for waste water and sewage, prepared by the following method:

[0055] S1 zeolite pretreatment: Stir the zeolite in hydrochloric acid solution, let it stand, and filter; boil the filtered zeolite in distilled water, wash it with distilled water, and finally put the zeolite in an oven to bake, and cool it for later use ;

[0056] S2 Preparation of zeolite-supported nano-titanium dioxide: Add 10 g of pretreated zeolite and 5 g of coupling agent to 200 mL of titanium dioxide sol, filter out the sieve after ultrasonication and let it stand, dry it at a constant temperature and roast it under nitrogen protection, and naturally cool down to 100 Stop flowing nitrogen at ℃, wash with distilled water after cooling to room temperature, and dry to obtain zeolite-loaded nano-titanium dioxide; wherein, the titanium dioxide sol can be prepared by the method described in CN104828916B.

[0057] S3 Soak bentonite in sulfuric acid, rinse with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com