Noble metal/amino MOFs selective hydrogenation catalyst, preparation method and application thereof

A hydrogenation catalyst and noble metal technology, which is applied in the preparation of hydroxyl compounds, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve problems such as high surface energy, small size, and easy agglomeration , to achieve high selectivity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

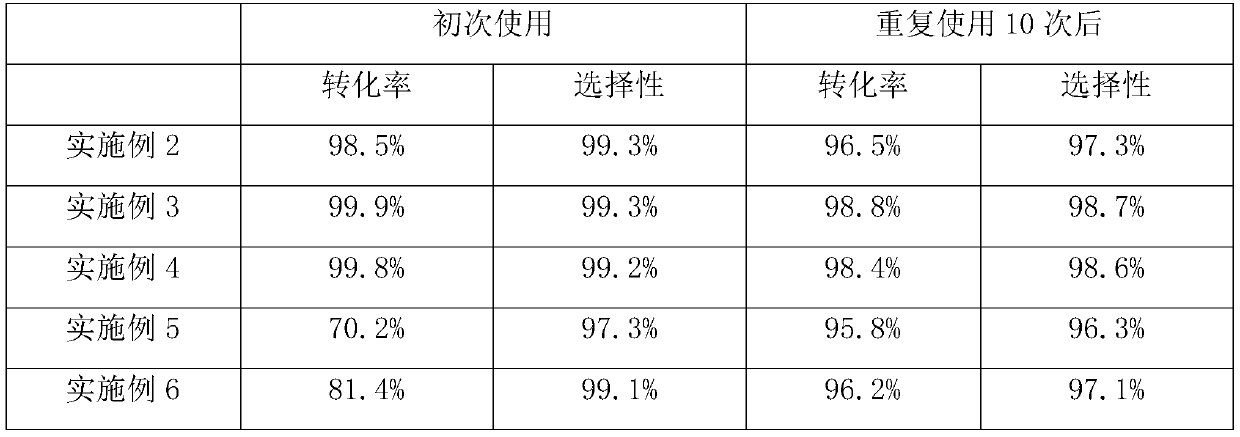

Examples

preparation example Construction

[0027] The preparation method of the supported noble metal / amino MOFs selective hydrogenation catalyst of the present invention comprises the following steps:

[0028] (1) Low-temperature liquid phase reduction to prepare single-atom noble metal sol;

[0029] (2) Load the single-atom noble metal sol in step (1) into the amino MOFs material to obtain a supported noble metal / amino MOFs selective hydrogenation catalyst.

[0030] Preferably, step (1) specifically includes the following steps: (1a) Slowly add the reducing agent solution to the noble metal precursor solution dropwise under the condition of -50-0°C, and after the dropwise addition, continue to complete the reaction to obtain a single atom Precious metal sol.

[0031] Preferably, the noble metal in step (1a) is Pt, and the noble metal precursor is a soluble salt of Pt, such as any one of H2PtCl4, H2PtCl6, K2PtCl6, Na2PtCl6, K2PtCl4 or Na2PtCl4 or a mixture of at least two .

[0032] Preferably, the concentration of...

Embodiment 1

[0056] Preparation of porous grade UiO66-NH2:

[0057] Weigh 0.8g of ZrCl4, 0.6g of 2-aminoterephthalic acid and dissolve in 200mL N,N-dimethylformamide to obtain a mixed solution; the mixed solution is sonicated for 5min, and then transferred to water with a Teflon cannula In a thermal reaction kettle, crystallize at 120°C for 24 hours to obtain the reaction product; after the reaction product is cooled to room temperature, wash with N,N-dimethylformamide solution and methanol solution three times respectively, and vacuum dry at 100°C for 12 hours to prepare Porous grade UiO-66-NH2.

Embodiment 2

[0059] Preparation of Supported Noble Metal / Amino MOFs Selective Hydrogenation Catalyst:

[0060] Configure 10mL 0.0001MH 2 PtCl 6 solution and 50mL0.001M hydrazine hydrate solution, H 2 PtCl 6 The solvent of the solution and the hydrazine hydrate solution is a mixture of water and ethanol with a volume ratio of 1:9.

[0061] H 2 PtCl 6 The solution and the hydrazine hydrate solution were placed in a high and low temperature box, and when the temperature dropped to -50°C, the hydrazine hydrate solution was slowly added dropwise to the H 2 PtCl 6 In the solution, after the dropwise addition, the reaction was continued at -50° C. for 2 h to obtain a single-atom Pt sol.

[0062] Weighed 1.95g of porous UiO66-NH2 into the above single-atom Pt sol, stirred for 10h, washed alternately with water and ethanol, and dried in vacuum at 100°C for 12h to prepare the supported noble metal / amino MOFs selective hydrogenation catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com