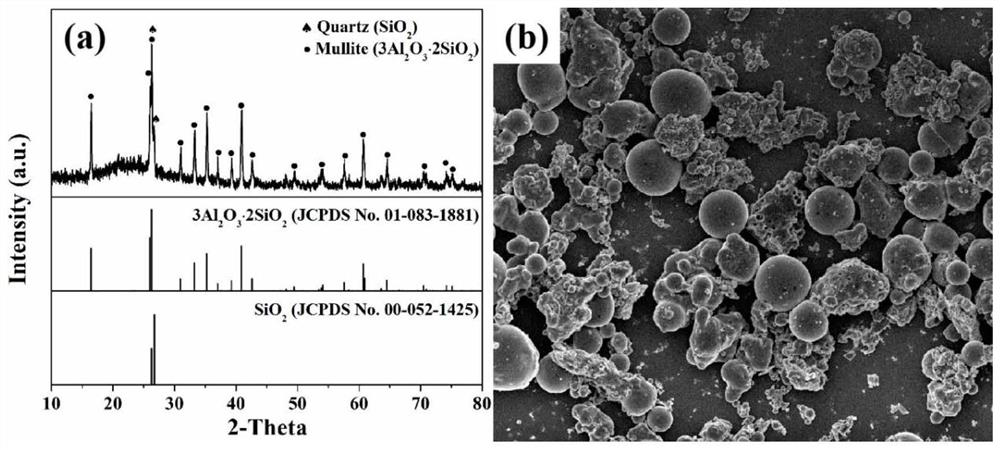

A kind of preparation of sio from fly ash 2 -al 2 o 3 Method for compounding aerogel materials

A technology of composite airgel and fly ash, applied in the field of mesoporous materials, achieves the effect of low cost, short process and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

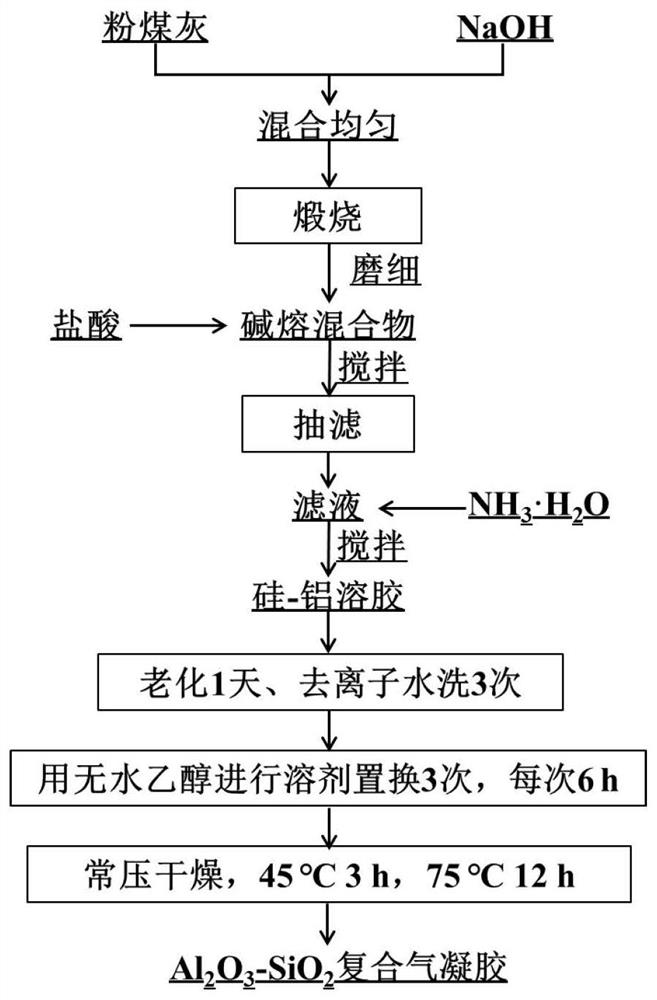

[0031] Example 1 (see the process flow figure 2 )

[0032] (1) Mix the fly ash and sodium hydroxide (mass ratio is 1:0.8) uniformly, place it in a muffle furnace, and calcinate at 350°C for 2 hours.

[0033] (2) Grind the alkali fusion mixture obtained in step (1), take 5 g of the alkali fusion mixture, add 30 ml of hydrochloric acid (5 mol / L) and 40 ml of deionized water, and stir until the reaction is complete.

[0034] (3) Filter the mixed solution in step (2) to obtain a solution containing silicon and aluminum.

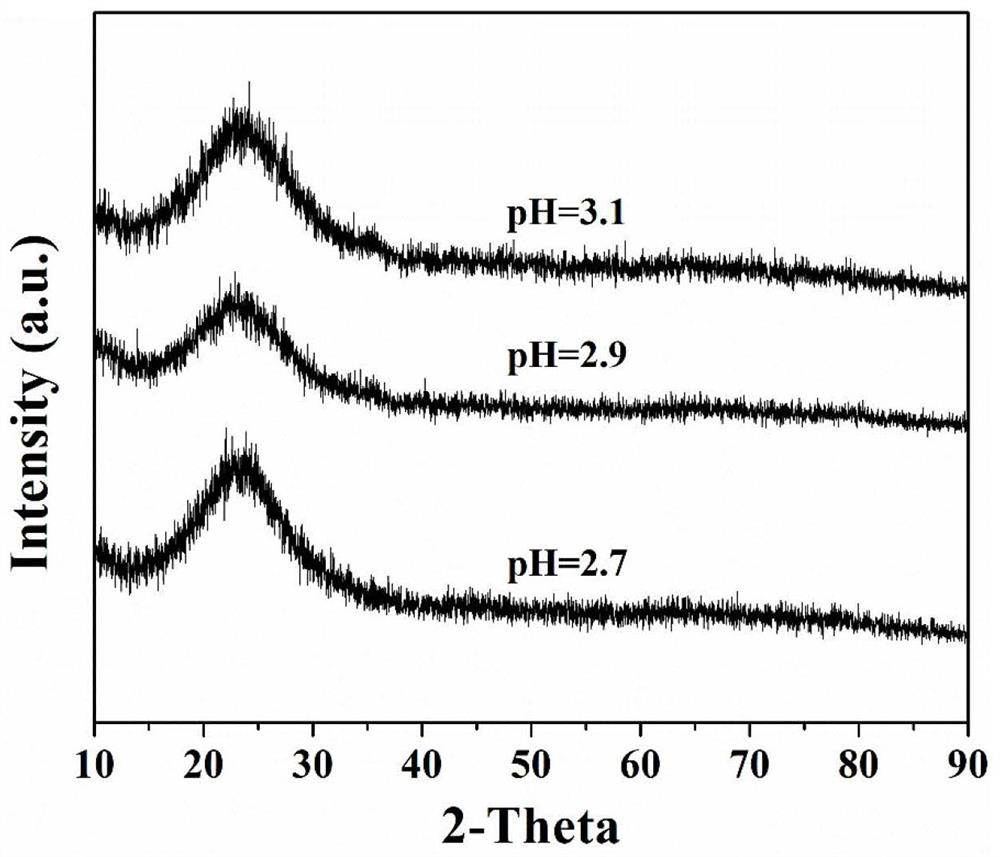

[0035] (4) Ammonia water (0.25mol / L) was added to the solution obtained in step (3), and the pH of the solution was controlled to be 2.7.

[0036] (5) After aging the gel obtained in step (4) for 1 day, wash it twice with deionized water.

[0037] (6) The gel obtained in step (5) is replaced with anhydrous ethanol for solvent replacement, and dried in an oven at 45° C. for 3 hours and at 75° C. for 12 hours.

Embodiment 2

[0038] Example 2 (see the process flow figure 2 )

[0039] (1) Mix the fly ash and sodium hydroxide (mass ratio is 1:1) evenly, place it in a muffle furnace, and calcine at 400 ° C for 1.5 hours.

[0040] (2) Grind the alkali fusion mixture obtained in step (1), take 6 g of the alkali fusion mixture, add 25 ml of hydrochloric acid (5 mol / L) and 30 ml of deionized water, and stir until the reaction is complete.

[0041] (3) Filter the mixed solution in step (2) to obtain a solution containing silicon and aluminum.

[0042] (4) Ammonia water (0.35mol / L) was added to the solution obtained in step (3), and the pH of the solution was controlled to be 2.9.

[0043] (5) After aging the gel obtained in step (4) for 2 days, wash it three times with deionized water.

[0044] (6) The gel obtained in step (5) is replaced with anhydrous ethanol for solvent replacement, and dried in an oven at 45° C. for 3 hours, 65° C. for 12 hours, and 75° C. for 12 hours.

Embodiment 3

[0045] Example 3 (see the process flow figure 2 )

[0046] (1) Mix the fly ash and sodium hydroxide (mass ratio is 1:1.2) evenly, place it in a muffle furnace, and calcine it at 500°C for 1 hour.

[0047] (2) Grind the alkali fusion mixture obtained in step (1), take 4 g of the alkali fusion mixture, add 35 ml of hydrochloric acid (5 mol / L) and 35 ml of deionized water, and stir until the reaction is complete.

[0048] (3) Filter the mixed solution in step (2) to obtain a solution containing silicon and aluminum.

[0049] (4) Ammonia water (0.5mol / L) was added to the solution obtained in step (3), and the pH of the solution was controlled to be 3.1.

[0050] (5) After aging the gel obtained in step (4) for 3 days, wash with deionized water 4 times.

[0051] (6) The gel obtained in step (5) was replaced by anhydrous ethanol, and dried in an oven at 45°C for 3 hours, 55°C for 6 hours, 65°C for 12 hours, and 75°C for 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com