Foamed ceramic with embossment effect and preparation method

A foamed ceramic and embossing technology, applied in the field of building decoration materials, can solve the problems of long processing time, increase production cost, affect the yield of board materials, etc., and achieve easy exhaust, prolong service life, and improve overall structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

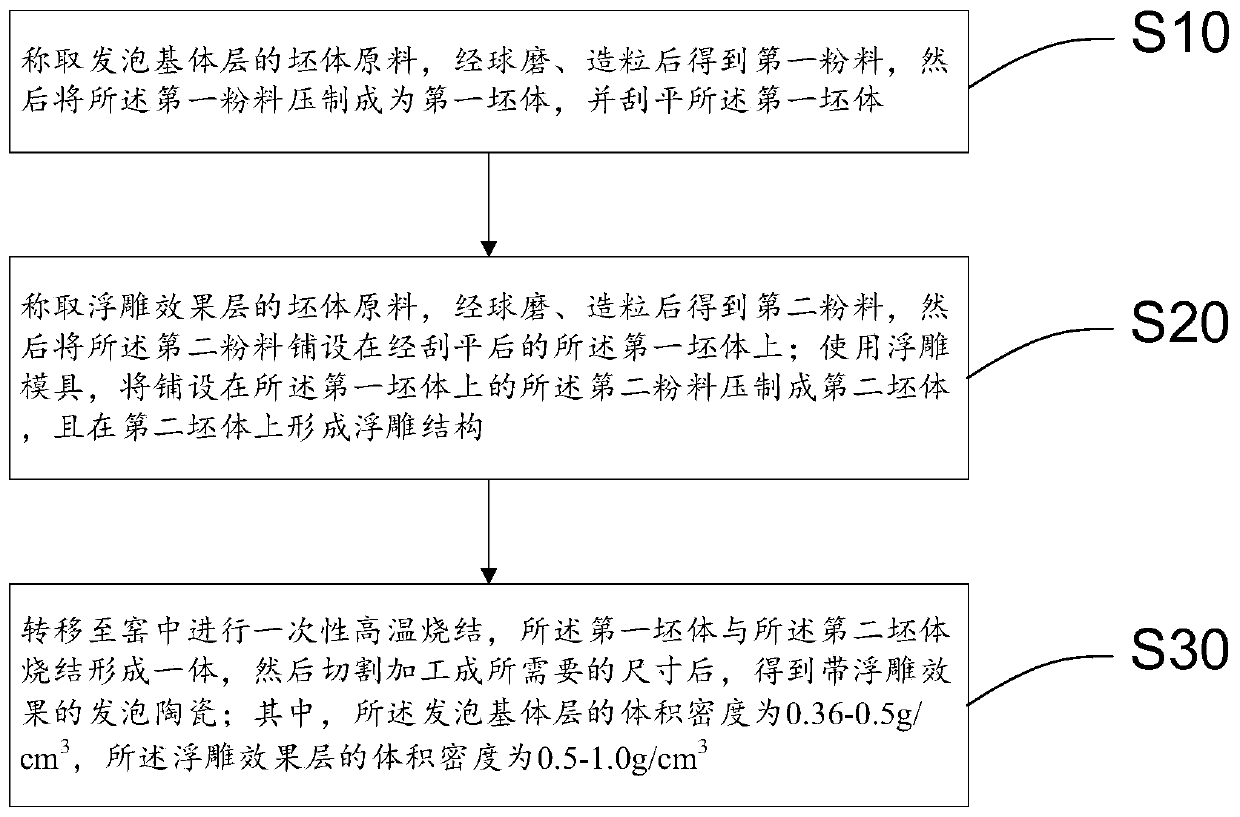

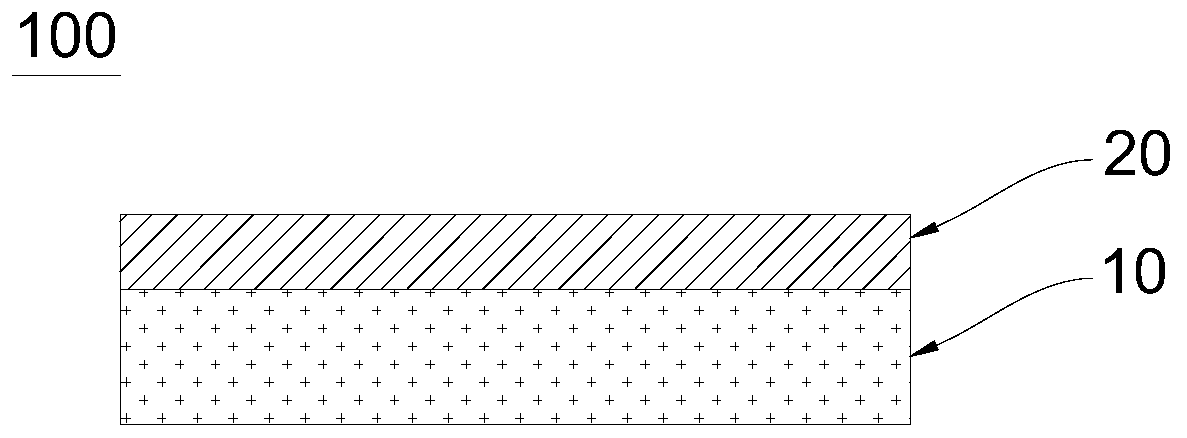

[0072] Such as figure 1 As shown, one embodiment of the present invention provides a method for preparing foamed ceramics with a relief effect, comprising the following steps:

[0073] S10, weighing the green body raw material of the foaming matrix layer, ball milling and granulating to obtain a first powder, then pressing the first powder into a first green body, and scraping the first green body;

[0074] S20. Weigh the green body raw material of the relief effect layer, and obtain the second powder after ball milling and granulation, and then lay the second powder on the scraped first green body; use a relief mold , pressing the second powder laid on the first green body into a second green body, and forming a relief structure on the second green body;

[0075] S30. Transferring to a kiln for one-time high-temperature sintering, the first green body and the second green body are sintered to form one body, and then cut and processed into required sizes to obtain foamed cera...

Embodiment 1

[0093] A method for preparing foamed ceramics with a relief effect, comprising the following steps:

[0094] Weigh the green body raw material of the foaming matrix layer, and its mass percentage is: tailings 66.5%, talc 20%, calcium oxide 2%, kaolin 10%, dispersant 1.0%, foaming agent 0.5%; The raw materials are transferred to a ball mill for ball milling to obtain a slurry, and then the slurry is sprayed and granulated to obtain a green body powder of the foamed matrix layer, and then the green body powder of the foamed matrix layer is pressed to form a foamed matrix layer blank body, and scrape the upper surface of the foamed matrix layer green body;

[0095] Weigh the green body raw material of the embossed effect layer, and its mass percentage content is: tailings 66.5%, talc 20%, calcium oxide 2%, kaolin 10%, dispersant 1.0%, foaming agent 0.3%; Transfer to a ball mill for ball milling to obtain a slurry, and then spray and granulate the slurry to obtain the green body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com