Production method of high-sulfur full-water-soluble nitrosulfur-based nitrogen fertilizer particles

A production method, fully water-soluble technology, applied in nitrogen fertilizer, ammonium nitrate fertilizer, fertilization device, etc., can solve problems such as inability to form eutectic, thick slurry, and inability to continue normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

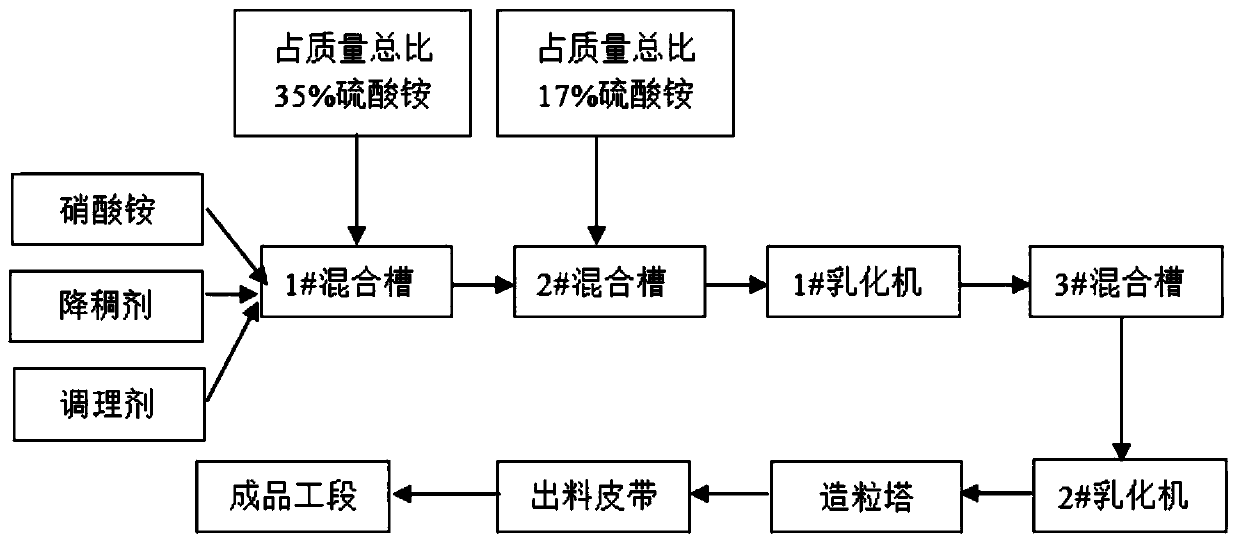

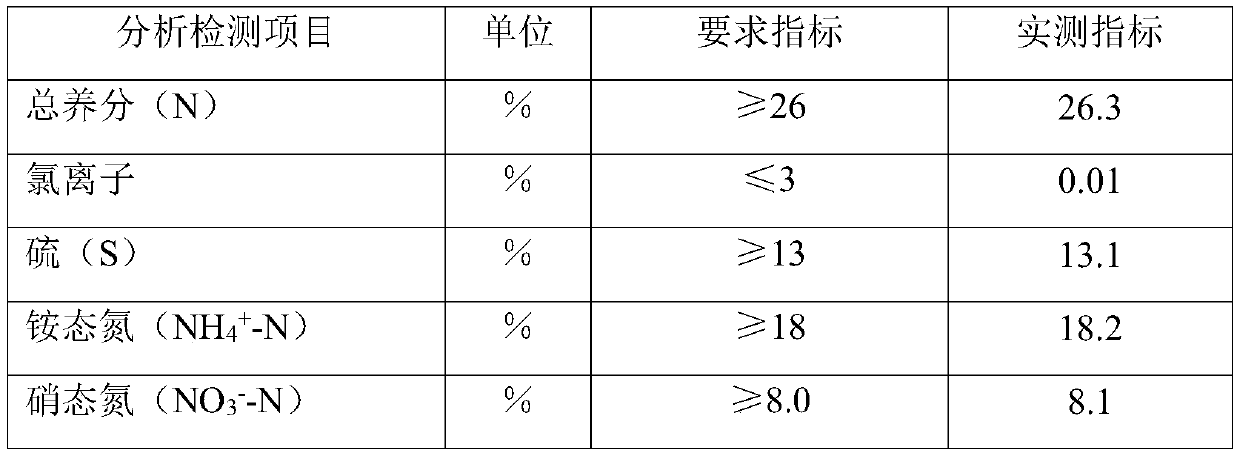

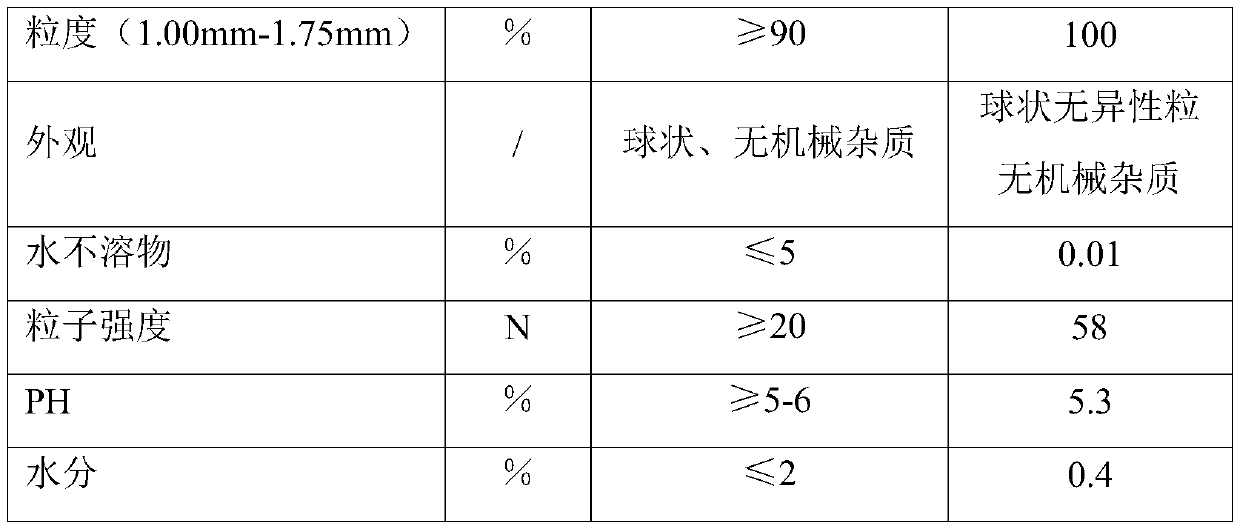

[0044] A method for producing quick-acting and long-acting high-sulfur full water-soluble nitrosulfur-based fertilizer granules, comprising the following steps:

[0045] 1) 95% of the ammonium nitrate produced by the ammonium nitrate plant is transported to the second-stage evaporation of ammonium nitrate in the high tower through a melt pump, and concentrated into a 99% ammonium nitrate solution, which accounts for 44% of the total mass ratio of ammonium nitrate after being measured by a mass flow meter The solution enters the primary mixing tank; at the same time, in the primary mixing tank, add a thickening agent (sodium dodecylsulfonate) accounting for 1% of the total mass ratio and a conditioning agent accounting for 3% of the total mass ratio after being metered by the metering belt under the tower (polyvinyl acetate) and solid ammonium sulfate accounting for 35% of the total mass ratio are fully mixed under stirring, and the temperature is controlled to 165-170°C.

[00...

Embodiment 2

[0049] A method for producing quick-acting and long-acting high-sulfur full water-soluble nitrosulfur-based fertilizer granules, comprising the following steps:

[0050] 1) 95% of the ammonium nitrate produced by the ammonium nitrate plant is transported to the second-stage evaporation of ammonium nitrate in the high tower through a melt pump, and concentrated into a 99% ammonium nitrate solution, which accounts for 51% of the total mass ratio of ammonium nitrate after being measured by a mass flow meter The solution enters the first-level mixing tank; at the same time, add a thickening agent (sodium dodecylsulfonate) accounting for 1% of the total mass ratio and a conditioning agent accounting for 3% of the total mass ratio after being metered by the metering belt under the tower in the primary mixing tank (polyvinyl acetate) and solid ammonium sulfate accounting for 25% of the total mass ratio are fully mixed under stirring, and the temperature is controlled to 165-170°C.

...

Embodiment 3

[0054] A method for producing quick-acting and long-acting high-sulfur full water-soluble nitrosulfur-based fertilizer granules, comprising the following steps:

[0055] 1) 95% of the ammonium nitrate produced by the ammonium nitrate plant is transported to the second-stage evaporation of ammonium nitrate in the high tower through a melt pump, and concentrated into a 99% ammonium nitrate solution, which accounts for 58% of the total mass ratio of ammonium nitrate after being measured by a mass flow meter Solution enters in the first-level mixing tank; Add simultaneously in the first-level mixing tank and account for 1% thickening agent (sodium lauryl sulphate) of the total mass ratio and the conditioner ( polyacrylamide) and solid ammonium sulfate accounting for 25% of the total mass ratio are fully mixed under stirring, and the temperature is controlled to 165-170°C.

[0056] 2) 13% of the total mass ratio of solid ammonium sulfate enters the secondary mixing tank together wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com