A kind of nano-modified epoxy resin anticorrosion coating and preparation method thereof

A water-based epoxy resin and epoxy resin technology, applied in the direction of epoxy resin coatings, anti-corrosion coatings, conductive coatings, etc., can solve the problems of not easy to disperse, easy to agglomerate, etc., achieve small thermal conductivity, high degree of bonding, and prevent damage sex cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

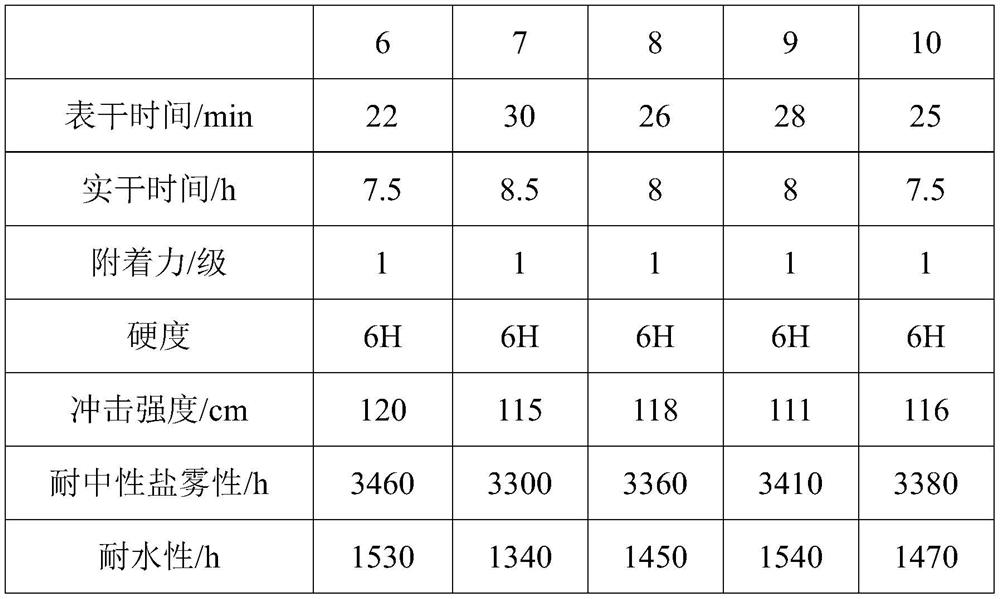

Examples

Embodiment 1

[0036] Example 1: Carbon / SiO 2 Coated K 2 Ti 6 o 13 Preparation of nanocomposites

[0037] The preparation method is as follows:

[0038] (1) Mix ethyl orthosilicate with absolute ethanol, γ-(2,3-epoxypropoxy)propyltrimethoxysilane, and then add K 2 Ti 6 o 13 Whiskers, polyethylene glycol 600, ultrasonically disperse for 30 minutes, after the dispersion is uniform, add deionized water, ultrasonically disperse for 30 minutes, slowly add hydrochloric acid ethanol solution with a concentration of 0.2mol / L, heat up to 45°C, and react for 35 minutes, A silica sol mixed system was prepared.

[0039] Among them, the molar ratio of ethyl orthosilicate, absolute ethanol, γ-(2,3-glycidoxy)propyltrimethoxysilane, and deionized water is 1:5:0.2:4; ethyl orthosilicate The molar ratio of the ester to the added hydrochloric acid ethanol solution of HCl is 1:0.06; tetraethyl orthosilicate, K 2 Ti 6 o 13 The mass ratio of whiskers and polyethylene glycol 600 is 5:5:1; K 2 Ti 6 o ...

Embodiment 2

[0041] Example 2: Carbon / SiO 2 Coated K 2 Ti 6 o 13 Preparation of nanocomposites

[0042] The preparation method is as follows:

[0043] (1) Mix ethyl orthosilicate with absolute ethanol, γ-(2,3-epoxypropoxy)propyltrimethoxysilane, and then add K 2 Ti 6 o 13 Whiskers, polyethylene glycol 600, ultrasonically disperse for 30 minutes, after the dispersion is uniform, add deionized water, ultrasonically disperse for 20 minutes, slowly add the hydrochloric acid ethanol solution with a concentration of 0.2mol / L, heat up to 45°C, and react for 40 minutes, A silica sol mixed system was prepared.

[0044] Among them, the molar ratio of ethyl orthosilicate, absolute ethanol, γ-(2,3-glycidoxy)propyltrimethoxysilane, and deionized water is 1:7:0.3:3; ethyl orthosilicate The molar ratio of the ester to the added hydrochloric acid ethanol solution of HCl is 1:0.08; tetraethyl orthosilicate, K 2 Ti 6 o 13 The mass ratio of whiskers and polyethylene glycol 600 is 5:5:1; K 2 Ti 6...

Embodiment 3

[0046] Example 3: Carbon / SiO 2 Coated K 2 Ti 6 o 13 Preparation of nanocomposites

[0047] The preparation method is as follows:

[0048] (1) Mix ethyl orthosilicate with absolute ethanol, γ-(2,3-epoxypropoxy)propyltrimethoxysilane, and then add K 2 Ti 6 o 13 Whiskers, polyethylene glycol 600, ultrasonically disperse for 20 minutes, after the dispersion is uniform, add deionized water, ultrasonically disperse for 25 minutes, slowly add the hydrochloric acid ethanol solution with a concentration of 0.2mol / L, heat up to 50°C, and react for 30 minutes, A silica sol mixed system was prepared.

[0049] Among them, the molar ratio of ethyl orthosilicate, absolute ethanol, γ-(2,3-glycidoxy)propyltrimethoxysilane, and deionized water is 1:6:0.1:3; ethyl orthosilicate The molar ratio of the ester to the added hydrochloric acid ethanol solution of HCl is 1:0.08; tetraethyl orthosilicate, K 2 Ti 6 o 13 The mass ratio of whiskers and polyethylene glycol 600 is 5:5:1; K 2 Ti 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com