Building thermal insulation coating material and preparation method thereof

A thermal insulation coating and building thermal insulation technology, applied in the field of coatings, can solve problems such as poor thermal insulation performance and thermal insulation performance that cannot meet its needs, and achieve good water resistance, good thermal insulation effect, excellent elasticity and elongation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

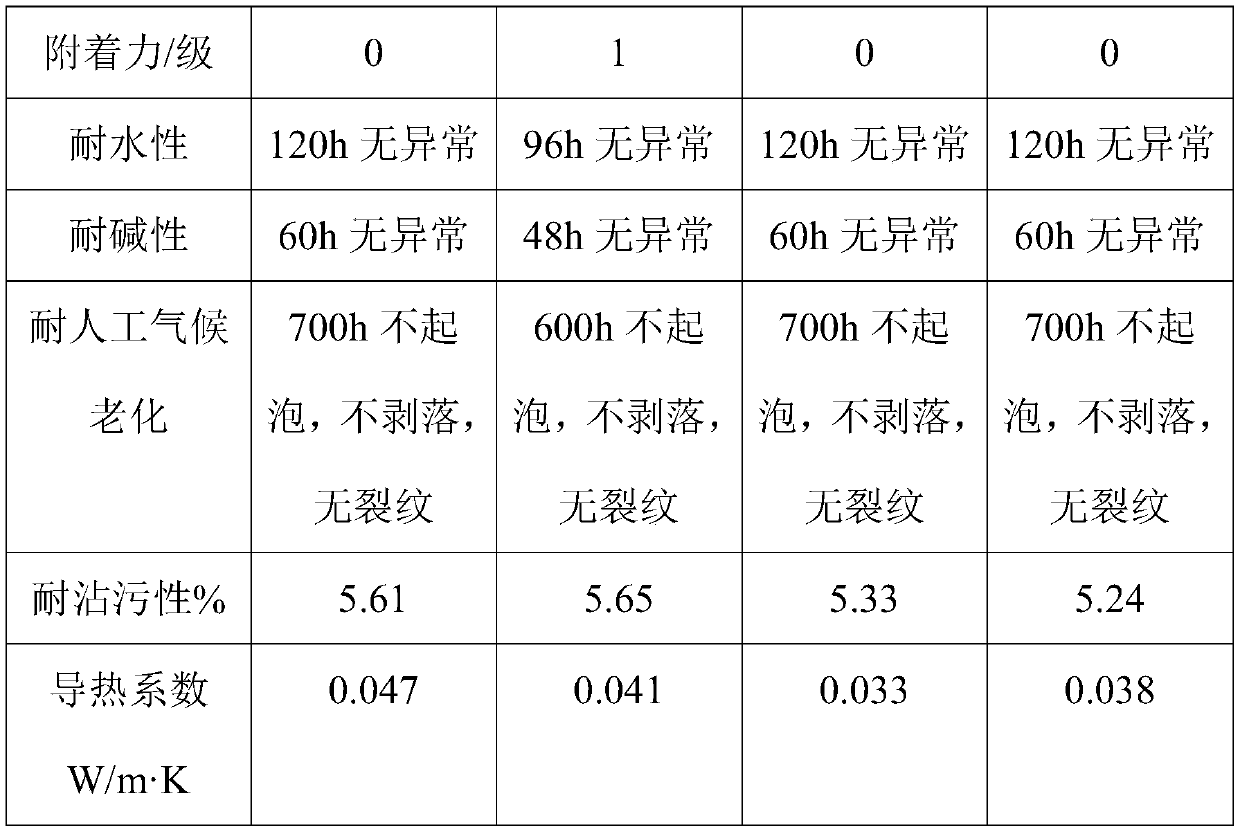

Embodiment 1

[0016] A kind of building thermal insulation paint that the present invention proposes, its raw material comprises by weight: 30 parts of elastic emulsion, 5 parts of film-forming auxiliary agent, 1 part of dispersant, 1 part of wetting agent, 5 parts of multifunctional auxiliary agent, 30 parts of ionized water, 1 part of glass hollow microspheres, SiO 2 Airgel 15 parts, titanium dioxide 1 part, thickener 3 parts.

[0017] Wherein, the preparation of the glass hollow microspheres is as follows: the glass hollow microspheres are added to a 93% acetone solution containing 5% silane coupling agent A-171 and 4% Dow Corning 3074, stirred at 40° C. for 30 min, suction filtered, and dried. instant;

[0018] Among them, the film-forming aid is dodecyl alcohol ester; the dispersant is sodium acrylate dispersant; the multifunctional additive is AMP-95; the thickener is sodium polyacrylate thickener; the wetting agent is polyoxyethylene octane Phenol ethers.

[0019] The preparation ...

Embodiment 2

[0021] A kind of building thermal insulation paint that the present invention proposes, its raw material comprises by weight: 50 parts of elastic emulsion, 2 parts of film-forming auxiliary agent, 3 parts of dispersant, 3 parts of wetting agent, 1 part of multifunctional auxiliary agent, 50 parts of ionized water, 10 parts of glass hollow microspheres, SiO 2 1 part of airgel, 30 parts of titanium dioxide, 1 part of thickener.

[0022] Wherein, the preparation of glass hollow microspheres is as follows: glass hollow microspheres are added to 97% acetone solution containing 8% silane coupling agent A-171 and 2% Dow Corning 3074, stirred at 50°C for 40min, suction filtered, and dried. instant;

[0023] Among them, the film-forming aid is propylene glycol methyl ether; the dispersant is sodium acrylate dispersant; the multifunctional additive is AMP-95; the thickener is sodium polyacrylate thickener; the wetting agent is polyoxyethylene polyoxypropylene embedded segment copolyme...

Embodiment 3

[0026] A kind of building thermal insulation coating proposed by the present invention, its raw material comprises by weight: 30 parts of elastic emulsion, 3 parts of film-forming auxiliary agent, 1.5 parts of dispersant, 2 parts of wetting agent, 2 parts of multifunctional auxiliary agent, 40 parts of ionized water, 4 parts of glass hollow microspheres, SiO 2 Airgel 8 parts, titanium dioxide 15 parts, thickener 1.5 parts.

[0027] Wherein, the preparation of the glass hollow microspheres is as follows: the glass hollow microspheres are added to a 95% acetone solution containing 6.5% silane coupling agent A-171 and 2.5% Dow Corning 3074, stirred at 45° C. for 30 min, suction filtered, and dried. instant;

[0028] Among them, the film-forming aid is dodecyl alcohol ester; the dispersant is sodium acrylate dispersant; the multifunctional additive is AMP-95; the thickener is sodium polyacrylate thickener; the wetting agent is polyoxyethylene octane A mixture of base phenol ethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com