A kind of mesoporous carbon reinforced iron-based composite material and its preparation method and application

An iron-based composite material and mesoporous carbon technology, applied in the direction of prosthesis, medical science, etc., can solve the problems of slow degradation of bone implants, insufficient osteogenic ability, limited biological activity, etc., to promote biomineralization, increase Quantity, the effect of increasing the corrosion current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

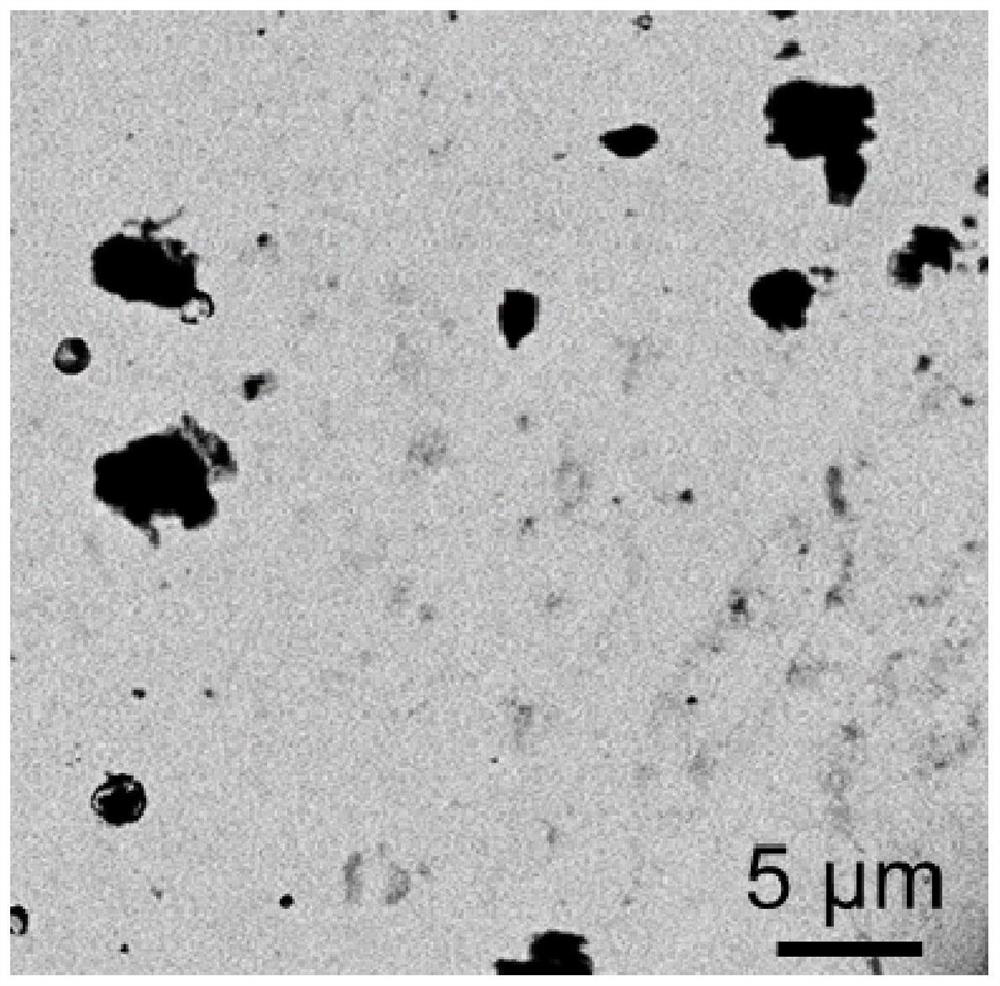

[0041] Weigh 1g of mesoporous carbon powder, its electrical conductivity is: 0.3S / cm, the average particle size is 3μm, and 99g of pure iron powder with an average particle size of 35μm are wetted in a ball mill under the action of a protective (nitrogen) atmosphere. Ball milling method, using dry alcohol as the ball milling medium at a speed of 350r / min for 4 hours to obtain a uniformly dispersed iron / mesoporous carbon mixed powder. Iron / mesoporous carbon implants were obtained after melting, cooling and solidification under the conditions of high-purity argon protection, laser power 100W, scanning speed 150mm / s, and powder coating thickness 60μm.

[0042] Microstructure observation revealed that mesoporous carbon was uniformly dispersed in the iron matrix, and mechanical tests showed that the ultimate compressive strength was 230Mpa.

[0043] After soaking in simulated body fluid for 30 days, the calculated degradation rate is 0.21 mm / year, and the surface is covered with a ...

Embodiment 2

[0045] Weigh 0.5g of mesoporous carbon powder, its conductivity is: 0.3S / cm, the average particle size is 3μm and 99.5g of pure iron powder with an average particle size of 35μm, in a ball mill under the action of a protective (argon) atmosphere Wet ball milling was carried out, and dry alcohol was used as the ball milling medium at a speed of 350 r / min for 4 hours to obtain a uniformly dispersed iron / mesoporous carbon mixed powder. Iron / mesoporous carbon implants were obtained after melting, cooling and solidification under the conditions of high-purity argon protection, laser power 100W, scanning speed 150mm / s, and powder coating thickness 60μm.

[0046]Microstructure observation revealed that mesoporous carbon was uniformly dispersed in the iron matrix, and mechanical tests showed that the ultimate compressive strength was 210Mpa.

[0047] After soaking in simulated body fluid for 30 days, the calculated degradation rate is 0.17mm / year, and the surface is covered with a lar...

Embodiment 3

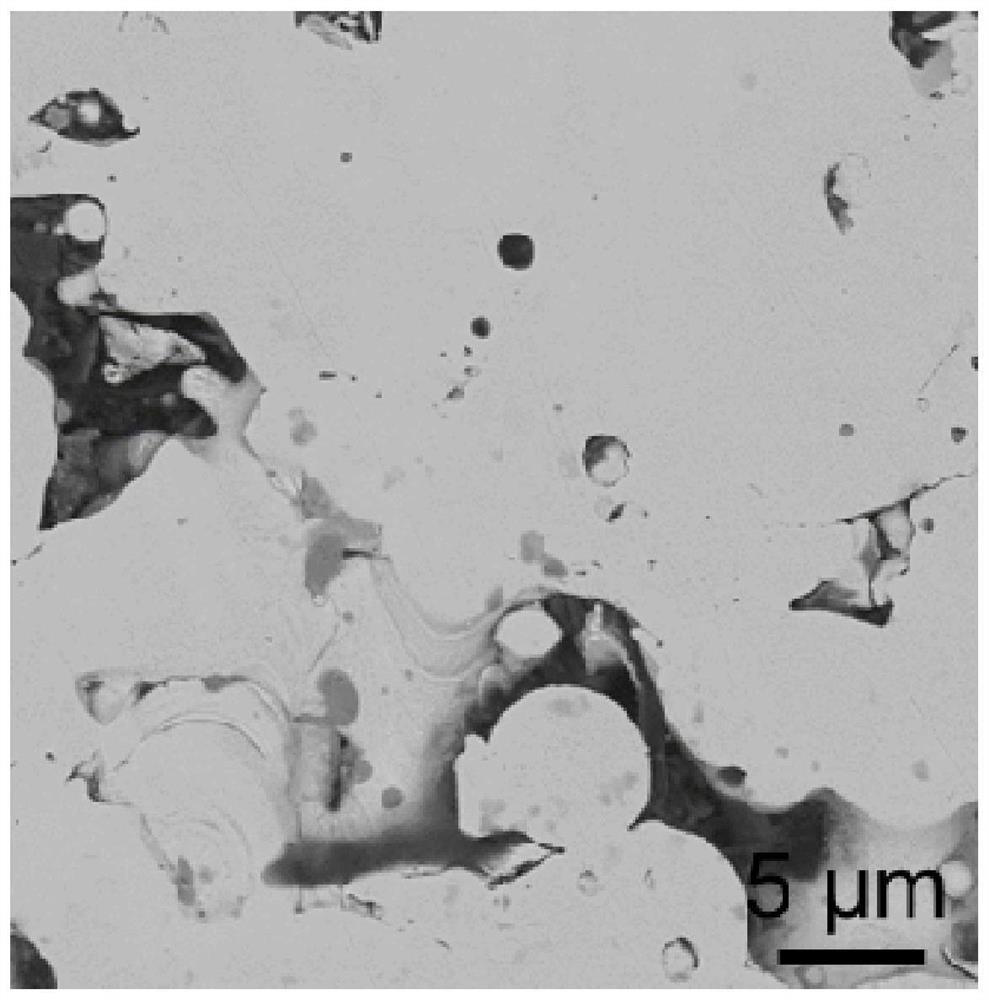

[0049] Weigh 2g of mesoporous carbon powder, its conductivity is: 0.3S / cm, the average particle size is 3μm and 95g of pure iron powder with an average particle size of 35μm, and it is carried out in a ball mill under the action of a protective (argon) atmosphere. Wet ball milling, using dry alcohol as the ball milling medium at a speed of 350r / min for 4 hours to obtain a uniformly dispersed iron / mesoporous carbon mixed powder. Iron / mesoporous carbon implants were obtained after melting, cooling and solidification under the conditions of high-purity argon protection, laser power 100W, scanning speed 150mm / s, and powder coating thickness 60μm.

[0050] Observation of the microstructure reveals that mesoporous carbon is uniformly dispersed in the iron matrix, and the mechanical test shows that the ultimate compressive strength is 204Mpa.

[0051] After soaking in simulated body fluid for 30 days, the calculated degradation rate is 0.18mm / year, and the surface is covered with a l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com