Multifunctional optical film and production method thereof

An optical film, multi-functional technology, applied in the field of optical film, can solve the problem of single function of anti-reflection film, achieve the effect of preventing ultraviolet aging and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

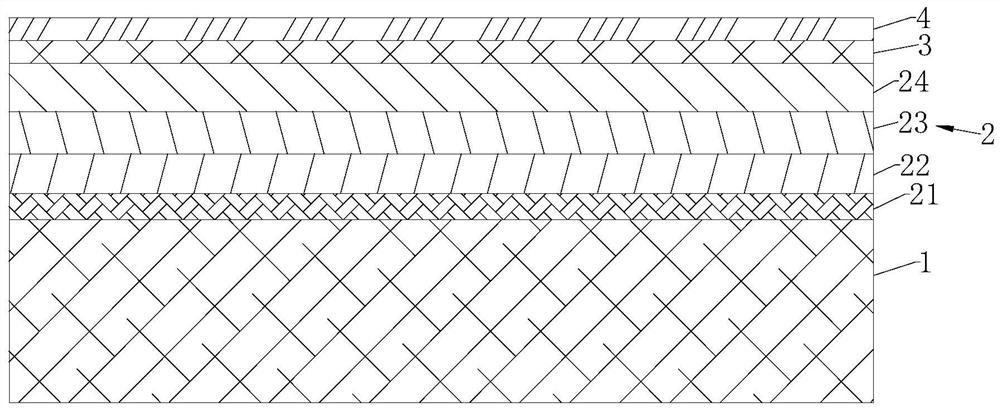

[0024] Embodiment one: if figure 1 As shown, the multifunctional optical film includes a substrate 1, which also includes an anti-reflection film layer 2, a chemically added hard coat layer 3 and a physically added hard coat layer 4 that are sequentially distributed on the surface of the substrate 1 from the inside to the outside;

[0025] The anti-reflection film layer 2 is a multi-layer anti-reflection film, including a cerium oxide film layer 21, an indium tin oxide film layer 22, a silicon nitride film layer 23 and a silicon dioxide film layer 24 distributed sequentially from the inside to the outside;

[0026] The chemical hard coat layer 3 is a wear-resistant film layer made by mixing methacryloxypropyl trimethoxysilane with epoxy resin;

[0027] The physical hard coating layer 4 is a diamond film layer.

[0028] The present invention also provides a method for preparing the above-mentioned multifunctional optical film, comprising the following steps:

[0029] (1) Surf...

Embodiment 2

[0042] Embodiment 2: The difference between Embodiment 2 and Embodiment 1 is that the chemical hard coat layer 3 is a UV curable film with vinyltriethoxysilane and 3-mercaptopropyltriethoxysilane as monomers . During preparation, use vinyltriethoxysilane and 3-mercaptopropyltriethoxysilane as monomers to prepare UV curing film hardening liquid, and spray the hardening liquid on the surface of the siliconized silicon film layer 24 to form a chemically hardened film. Dura layer 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com