Cut tobacco containing polysaccharides from tobacco leaves and polysaccharides derived from them with high moisture retention

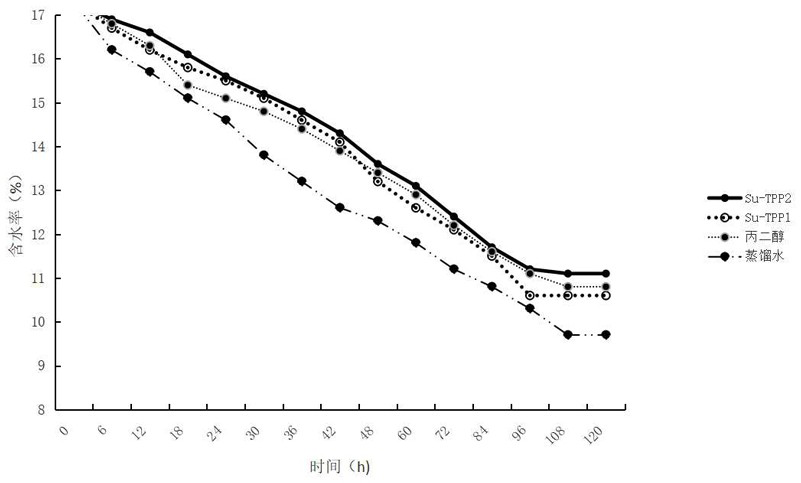

A technology of tobacco leaves and polysaccharides, applied in the field of tobacco, can solve the problems of affecting the natural flavor of cigarettes, low antioxidant activity, poor cigarette aroma coordination, etc., and achieves the effects of good in vitro antioxidant activity, simple preparation method and slow water loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

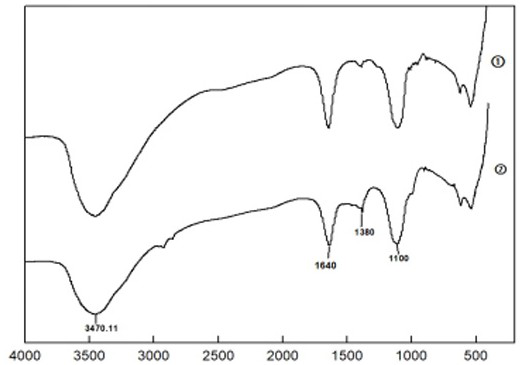

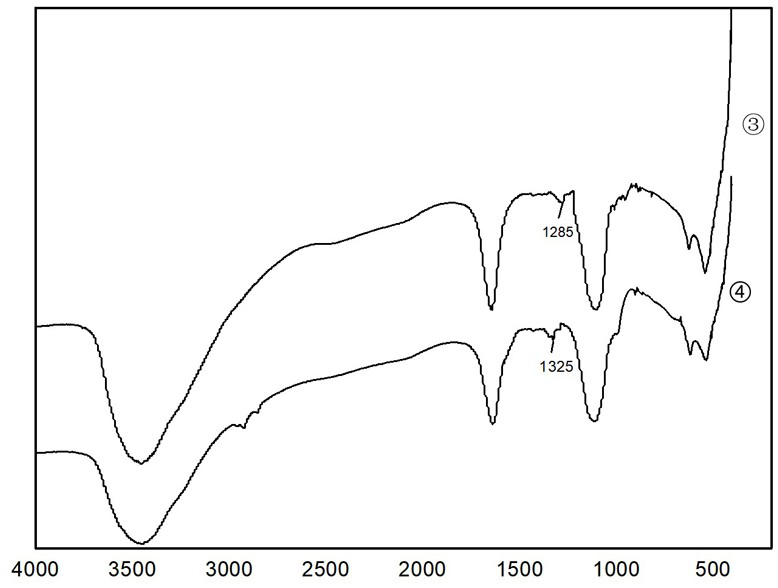

[0027] The embodiment of the present invention provides a kind of preparation method of succinylated tobacco polysaccharide, comprising the following steps:

[0028] (1) Extraction of polysaccharides from tobacco leaves;

[0029] (2) Refining of polysaccharides from tobacco leaves;

[0030] (3) Succinylation of polysaccharides from tobacco leaves.

[0031] The extraction of tobacco polysaccharides in step (1) is carried out as follows: grind the tobacco leaves and pass through a 40-mesh sieve, add petroleum ether to soak for 3-5 hours, and then filter to obtain the filter residue; add 300mL 80% ethanol to the filter residue for reflux extraction 2 time, 2h / time, suction filtration, the filter residue is dried and pulverized at 60°C for later use; add distilled water at about 60°C to the dried filter residue, the mass ratio of filter residue to distilled water is 1:35, and then put it into an ultrasonic cleaner, Sonicate at 380-400 W for 8-10 min, then filter, take the filtra...

Embodiment 1

[0049] Embodiment 1 of the present invention provides a kind of preparation method of succinylated tobacco polysaccharide, comprising the following steps:

[0050] (1) Extraction of polysaccharides from tobacco leaves: Grind the tobacco leaves and pass through a 40-mesh sieve, soak in petroleum ether for 3 hours, and then extract the filter residue by suction; add 300mL 80% ethanol to the filter residue for reflux extraction twice, 2h each time, and suction filter , the filter residue was dried and pulverized at 60°C for later use; distilled water at 60°C was added to the dried filter residue, the mass ratio of the filter residue to distilled water was 1:35, and then placed in an ultrasonic cleaner and ultrasonically treated at 380 W for 8 min. After filtering, the filtrate was taken for concentration and ethanol precipitation with absolute ethanol to obtain the tobacco leaf crude polysaccharide precipitate, and the calculated yield of tobacco leaf crude polysaccharide was 3.18...

Embodiment 2

[0054] Embodiment 2 of the present invention provides a kind of preparation method of succinylated tobacco polysaccharide, comprising the following steps:

[0055] (1) Extraction of polysaccharides from tobacco leaves: Grind the tobacco leaves and pass through a 40-mesh sieve, soak them in petroleum ether for 4 hours, and then extract the filter residue by suction; add 300mL of 80% ethanol to the filter residue for reflux extraction twice, 2h each time, and suction filter , the filter residue was dried and pulverized at 60°C for later use; distilled water at 60°C was added to the dried filter residue, the mass ratio of the filter residue to distilled water was 1:35, and then placed in an ultrasonic cleaner, ultrasonically treated at 400W for 8 min, and then Filtrate, take the filtrate for concentration, and use absolute ethanol to ethanol precipitate to obtain the tobacco leaf crude polysaccharide precipitate. The calculated yield of tobacco leaf crude polysaccharide is 3.57%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com