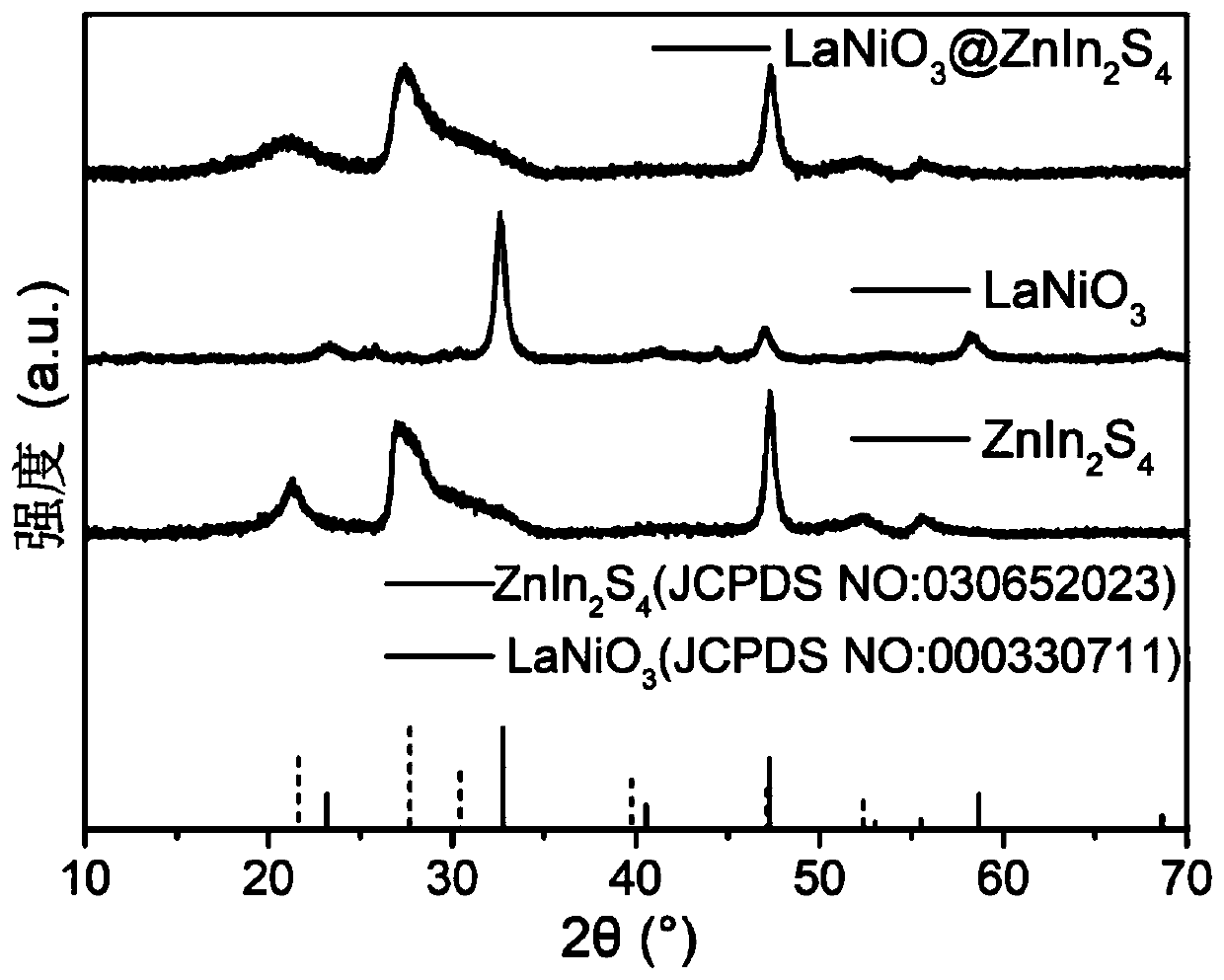

Preparation and Application of ZnIn2S4 Based Core-Shell Composite Photocatalyst

A technology of znin2s4 and complex light, which is applied in the direction of physical/chemical process catalysts, hydrogen/synthesis gas production, hydrogen production, etc., can solve the problems of catalyst stability reduction, catalyst stability not being improved, and inability to suppress photocorrosion, etc. Achieve the effects of improving stability, inhibiting photocorrosion, and improving photocatalytic reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] NeO 3 @ZnIn 2 S 4 The preparation method of the composite photocatalyst of core-shell structure is, but not limited to the following method, which specifically includes the following steps carried out in sequence:

[0040] S1LaNiO 3 Solution preparation: LaNiO 3 The nanocubes are dispersed in deionized water, and the pH value is adjusted to 1.5-3 to obtain LaNiO 3 Suspension solution; LaNiO 3 The ratio of nano cubes to deionized water is 50-150 mg: 50-150 mL.

[0041] S2 LaNiO 3 The suspension solution is mixed with zinc salt compound, indium salt compound and sulfur-containing compound to obtain a mixed solution;

[0042] S3 After the mixed solution undergoes condensation-reflux reaction, the precipitate is collected, and the light yellow powder obtained after washing and drying is LaNiO 3 @ZnIn 2 S 4 Core-shell composite photocatalyst.

[0043] Wherein, in step S2, the mixed solution is stirred under ultrasonic waves for 1-2 hours.

[0044] Wherein, in ste...

Embodiment 1

[0053] A kind of composite photocatalyst, it is mainly ZnIn 2 S 4 Nanosheets supported on LaNiO 3 nanocube surface, the formation of LaNiO 3 @ZnIn 2 S 4 Core-shell composite photocatalyst.

Embodiment 2

[0055] NeO 3 @ZnIn 2 S 4 The preparation method of core-shell type composite photocatalyst, it comprises the following steps:

[0056] S1LaNiO 3 Preparation of nanocubes

[0057] 0.5 parts by mass of La(NO 3 ) 3 ·6H 2 O, 0.4 parts by weight of Ni(NO 3 ) 2 ·6H 2 O. 0.4 parts by weight of polyvinylpyrrolidone and 0.4 parts by weight of glycine were dissolved in 90 ml of deionized water, and the pH of the solution was adjusted to 7.9 with ammonia water. The above solution was transferred to a reaction kettle and reacted at 190°C for 14h. The obtained product was filtered with deionized water and ethanol solution, dried, and calcined at 700 °C for 3 h to obtain LaNiO 3 nanocube;

[0058] S2LaNiO 3 Solution preparation: 50mg of LaNiO 3 The nanocubes were dispersed in deionized water, and the pH value was adjusted to 1.5 to obtain LaNiO 3 suspension solution;

[0059] S3 LaNiO 3 suspension solution and ZnCl 2 , InCl 3 Mixed with thioacetamide to get the mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com