One-component polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof, one-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of low tensile strength, poor erosion resistance and wear resistance, and easy occurrence of coating films, so as to improve the Effects of mechanical properties and foreign body puncture resistance, excellent mechanical properties and foreign body puncture resistance, good flexibility and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

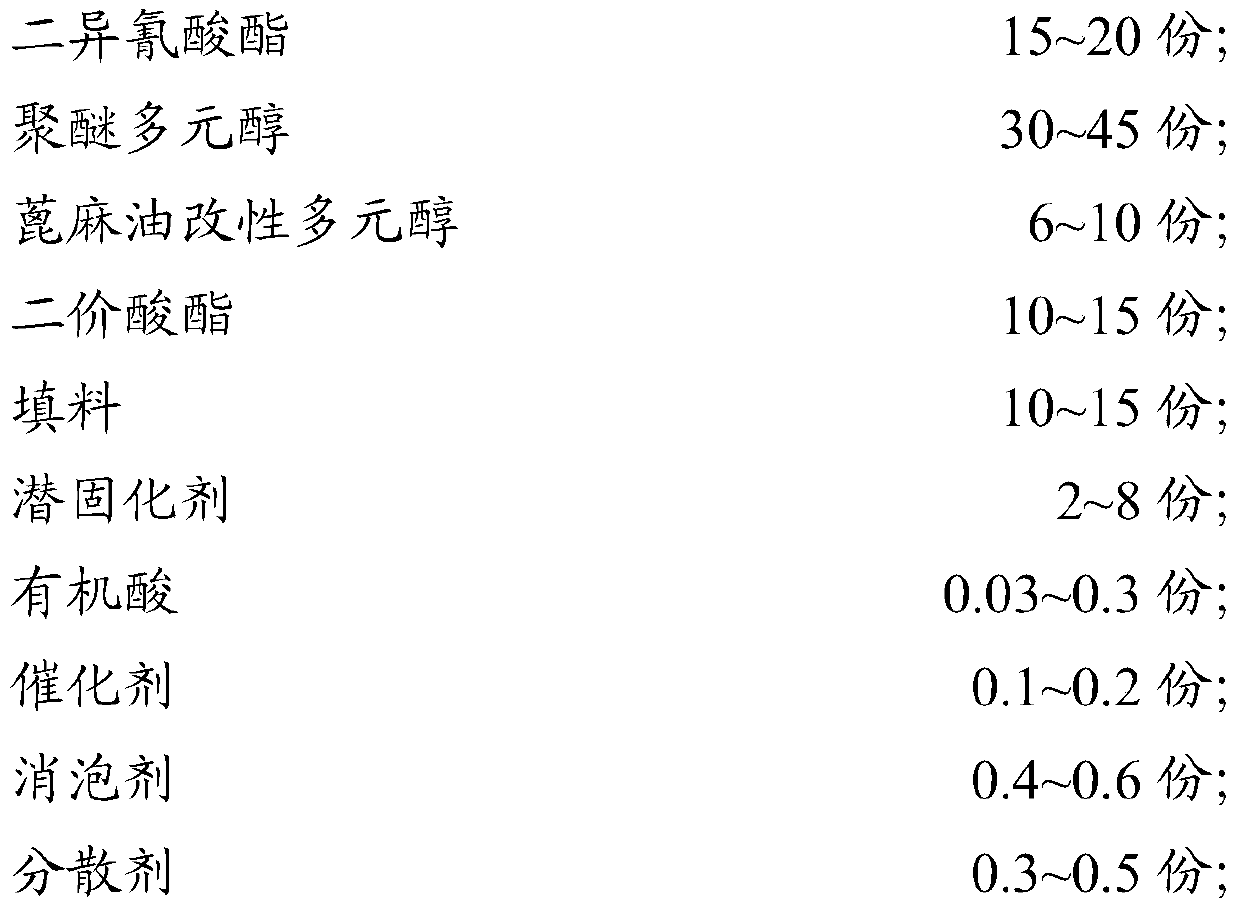

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing the one-component polyurethane waterproof coating described in the above technical scheme, comprising the steps of:

[0048] (1) mixing polyether polyol, filler, defoamer and dispersant, then grinding and drying to obtain a premix;

[0049] (2) In a protective atmosphere, add the dibasic acid ester solution of diisocyanate to the premix, heat up to 70-90°C and react at a constant temperature for 2 hours, then add the dibasic acid ester solution of the catalyst, and continue the constant temperature reaction for 0.5-1 hour; After completion, lower the temperature to 40-50°C, add the dibasic acid ester solution of castor oil-modified polyol, react at constant temperature for 0.5-1 hour, then add latent curing agent, organic acid and dibasic acid ester, and then undergo defoaming to obtain One-component polyurethane waterproof coating.

[0050] The invention mixes polyether polyol, filler, defoamer and dispersant,...

Embodiment 1

[0060] With 240g epoxy propylene polyether trihydric alcohol (number average molecular weight 5000), 10g epoxy propylene polyether trihydric alcohol (number average molecular weight 300), 15g epoxy propylene polyether glycol (number average molecular weight 1000), 5g Bisphenol A polyoxyethylene ether (hydroxyl value 230mKOH / g), 30g polytetramethylene glycol (number average molecular weight 2000), 2g carbon black, 70g titanium dioxide, 15g organic bentonite, 1.5g polyacrylate dispersant and 1.8g Silicone defoaming agent, after mixing evenly, grind it twice with a three-roller mill, and then dry it in a double planetary stirring tank at 120°C and -0.092MPa vacuum conditions for 2 hours to obtain a premix;

[0061] Cool the premixed material to 50°C, replace the vacuum with nitrogen to obtain a protective atmosphere, add the divalent acid ester solution of HMDI (containing 150g of HMDI), and then raise the temperature to 80°C for constant temperature reaction for 2h, then add the ...

Embodiment 2

[0063] With 240g epoxy propylene polyether trihydric alcohol (number average molecular weight 5000), 5g epoxy propylene polyether trihydric alcohol (number average molecular weight 300), 15g epoxy propylene polyether glycol (number average molecular weight 1000), 7g Bisphenol A polyoxyethylene ether (hydroxyl value 345mKOH / g), 15g polytetramethylene glycol (number average molecular weight 1000), 2g carbon black, 70g titanium dioxide, 15g organic bentonite, 1.5g polyacrylate dispersant and 1.8g Silicone defoaming agent, after mixing evenly, grind it twice with a three-roller mill, and then dry it in a double planetary stirring tank at 120°C and -0.092MPa vacuum conditions for 2 hours to obtain a premix;

[0064]Cool the premixed material to 50°C, replace the vacuum with nitrogen to obtain a protective atmosphere, add the divalent acid ester solution of HMDI (containing 150g of HMDI), and then raise the temperature to 80°C for constant temperature reaction for 2h, then add the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com