Intelligent interval pumping control system of oil field beam-pumping unit and control method thereof

A technology of a beam pumping unit and a control system, which is applied to the automatic control system of drilling, earthwork drilling and production, and production fluids, etc. It can solve problems such as inability to achieve high-efficiency operation, low efficiency of the mechanical production system, and production decline, and achieve The effect of solving the decline in production, solving the low efficiency of the mechanical mining system, and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

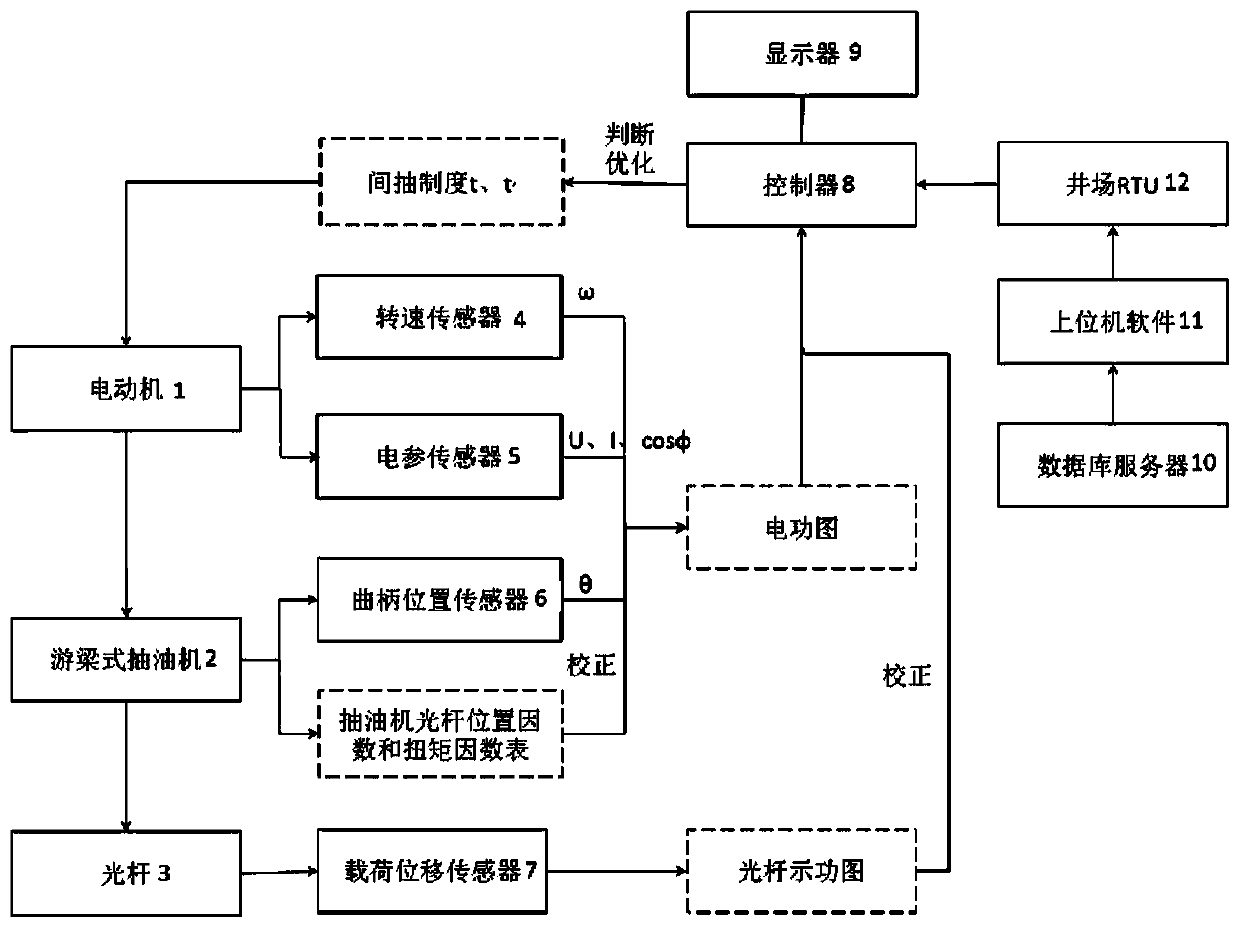

[0054] The first embodiment of the present invention relates to an intelligent inter-pumping control system for beam pumping units in oilfields, such as figure 1 As shown, it includes a database server 10, a host computer 11, a well site RTU 12 and a controller 8 that are electrically connected in sequence. The controller 8 is electrically connected to the display 9 and the motor 1. The motor 1 is connected to and drives the beam pumping unit 2. The donkey head of the beam pumping unit 2 is connected to the polished rod 3, the motor 1 is equipped with a speed sensor 4 and an electric parameter sensor 5, a crank position sensor 6 is installed on the crank of the beam pumping unit 2, and a load displacement sensor 7 is installed on the polished rod 3;

[0055] The rotational speed sensor 4 , the electric parameter sensor 5 , the crank position sensor 6 and the load displacement sensor 7 are respectively connected with the controller 8 .

no. 2 approach

[0060] Different from the first embodiment, in this embodiment, the electric parameter sensor 5 includes a voltage sensor for measuring the voltage of the motor 1 , a current sensor for measuring the current of the motor 1 , and a power factor sensor for measuring the power factor of the motor 1 .

[0061] In addition, further, the following data are stored in the database server 10: the allowable value P of intermittent pumping and menstrual stop, the daily production fluid V of the oil well 日产液 , crude oil volume water content n w , the density of water ρ w , the density ρ of crude oil without water o , casing inner diameter ф 套 , tubing outer diameter ф 油 , oil well pump diameter D p , stroke S, sprint n 冲 , stroke loss λ, oil well pump leakage Q 漏 , the gas-liquid ratio R at the pump suction port, the pump clearance volume coefficient K, and the submerged pressure P of the well pump s , the discharge outlet pressure P of the well pump d , the variable process index...

no. 3 approach

[0064] On the basis of the intelligent inter-pumping control system of the beam pumping unit in the oil field, the present invention also protects a control method utilizing the intelligent inter-pumping control system of the beam pumping unit in the oil field, which specifically includes the following steps:

[0065] In step S1, the upper computer 11 calls the data stored in the database server 10, and calculates the initial value of the thinning system according to the called data;

[0066] Step S2, the initial value of the thinning system is sent to the well site RTU12 by the host computer 11, and the controller 8 retrieves the initial value of the thinning system from the well site RTU12;

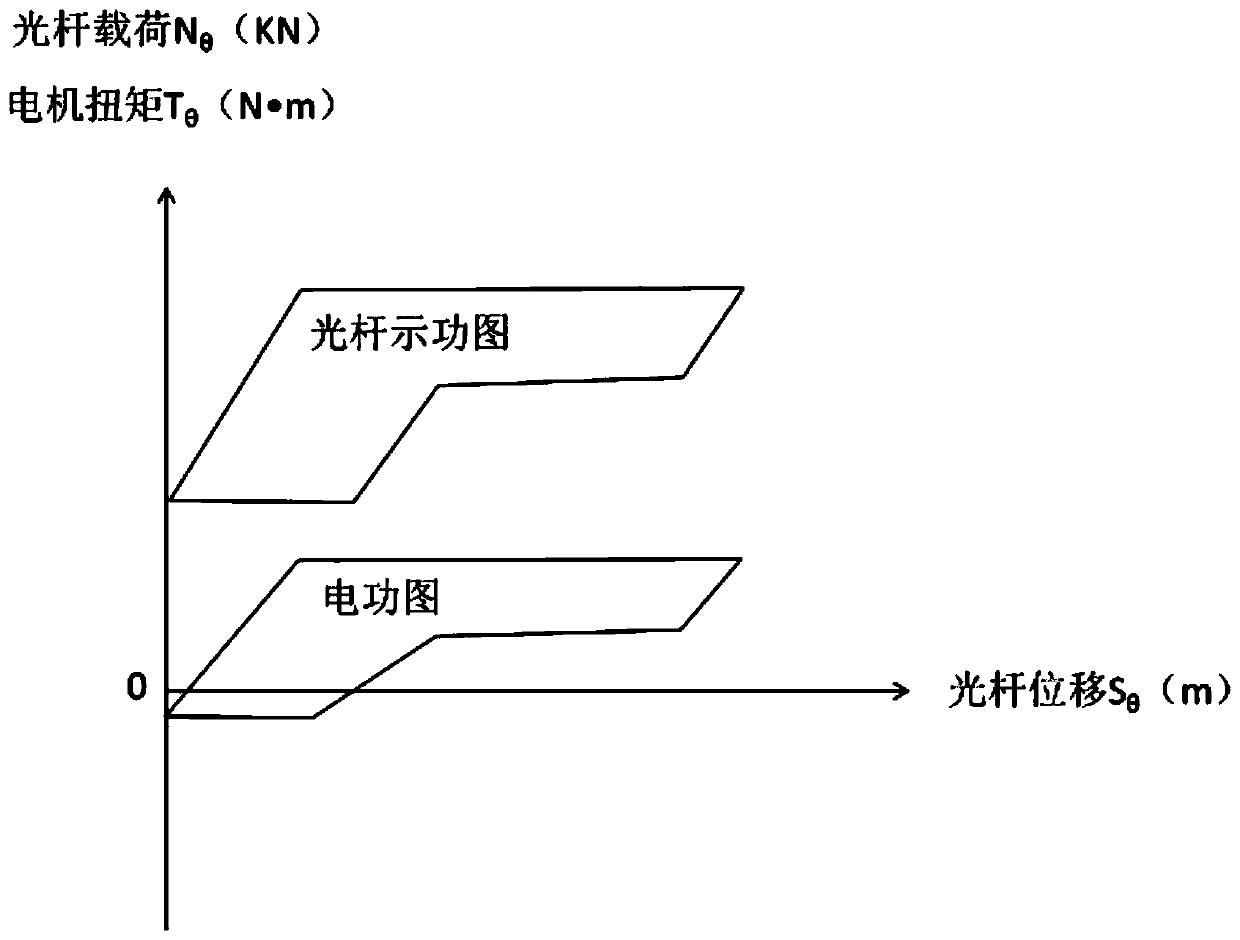

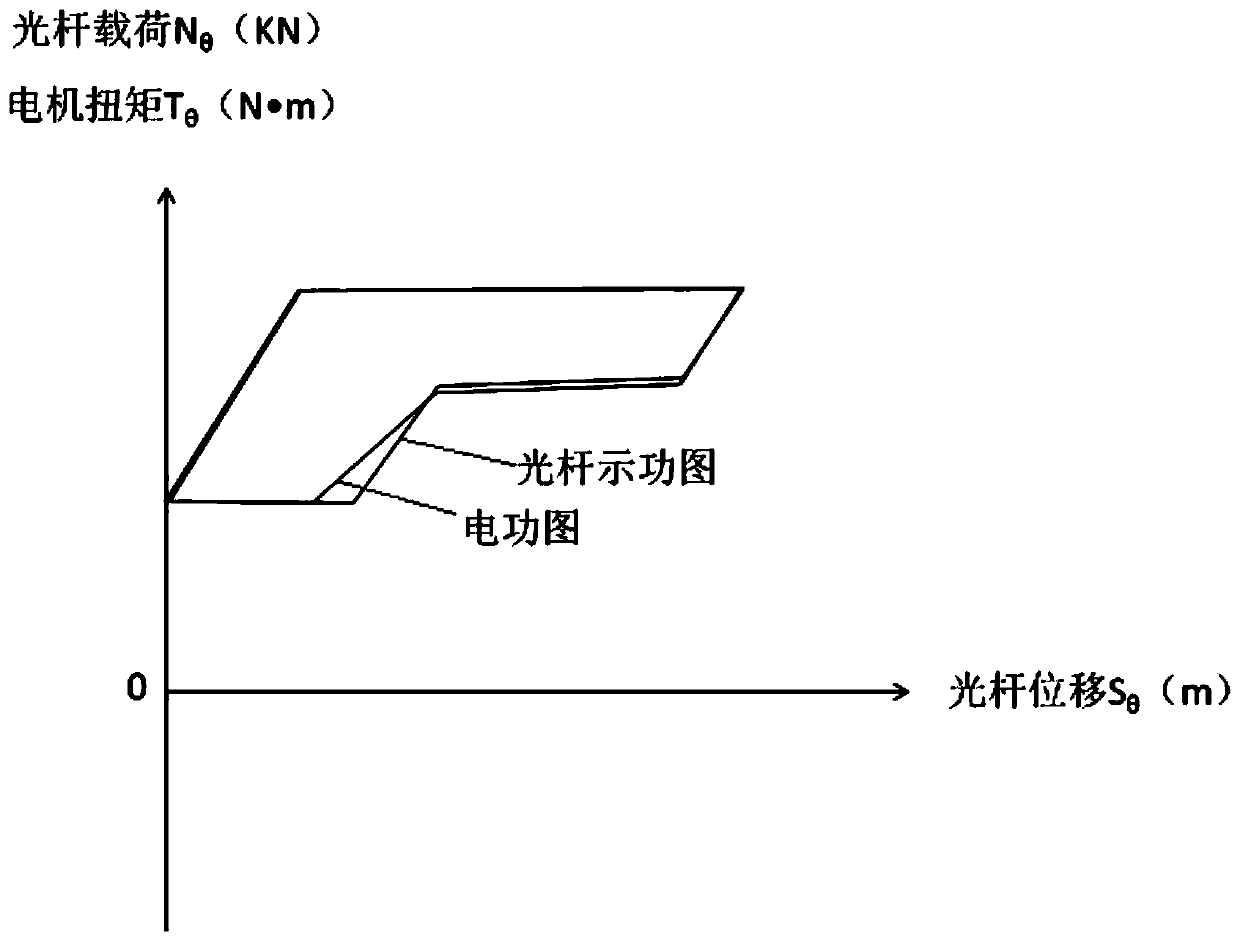

[0067] In step S3, the controller 8 draws a polished rod indicator diagram according to the load displacement data transmitted by the load displacement sensor 7, and reflects it on the display 9;

[0068] Step S4, the controller 8 draws the electric power diagram of the motor according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com