Preparation method of anti-inflammatory alga extract applied to cosmetics

A technology of cosmetics and extracts, which is applied in the field of preparation of seaweed anti-inflammatory extracts, can solve the problems of unsuitable anti-inflammatory cosmetics and unfavorable inflammation recovery, and achieve the effect of improving transdermal effect and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

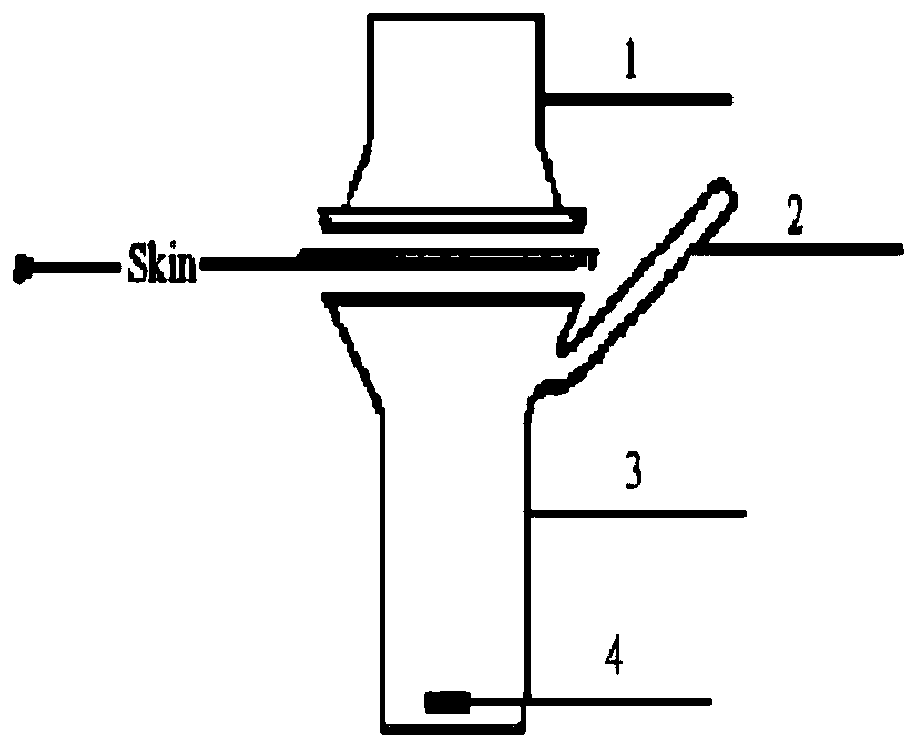

Image

Examples

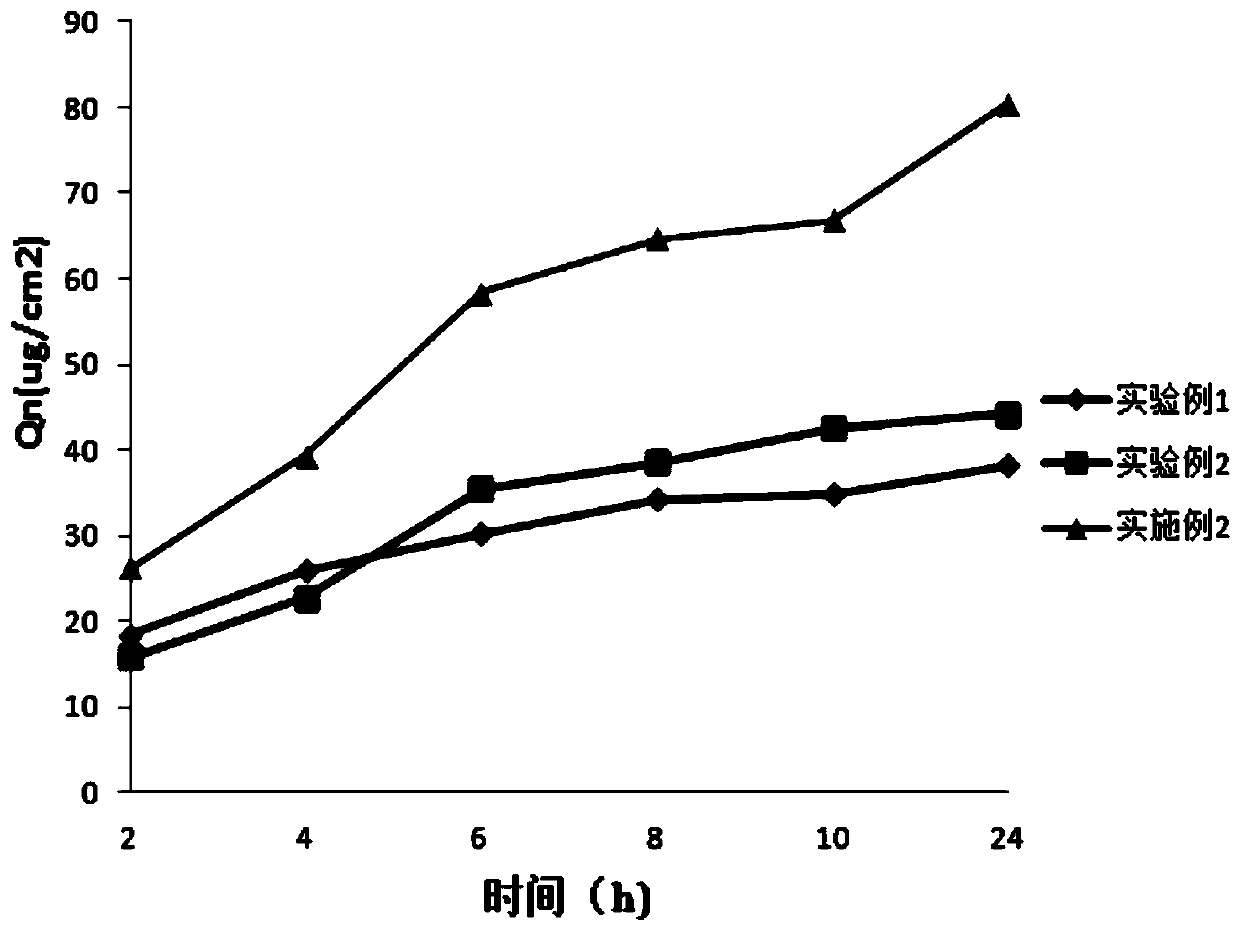

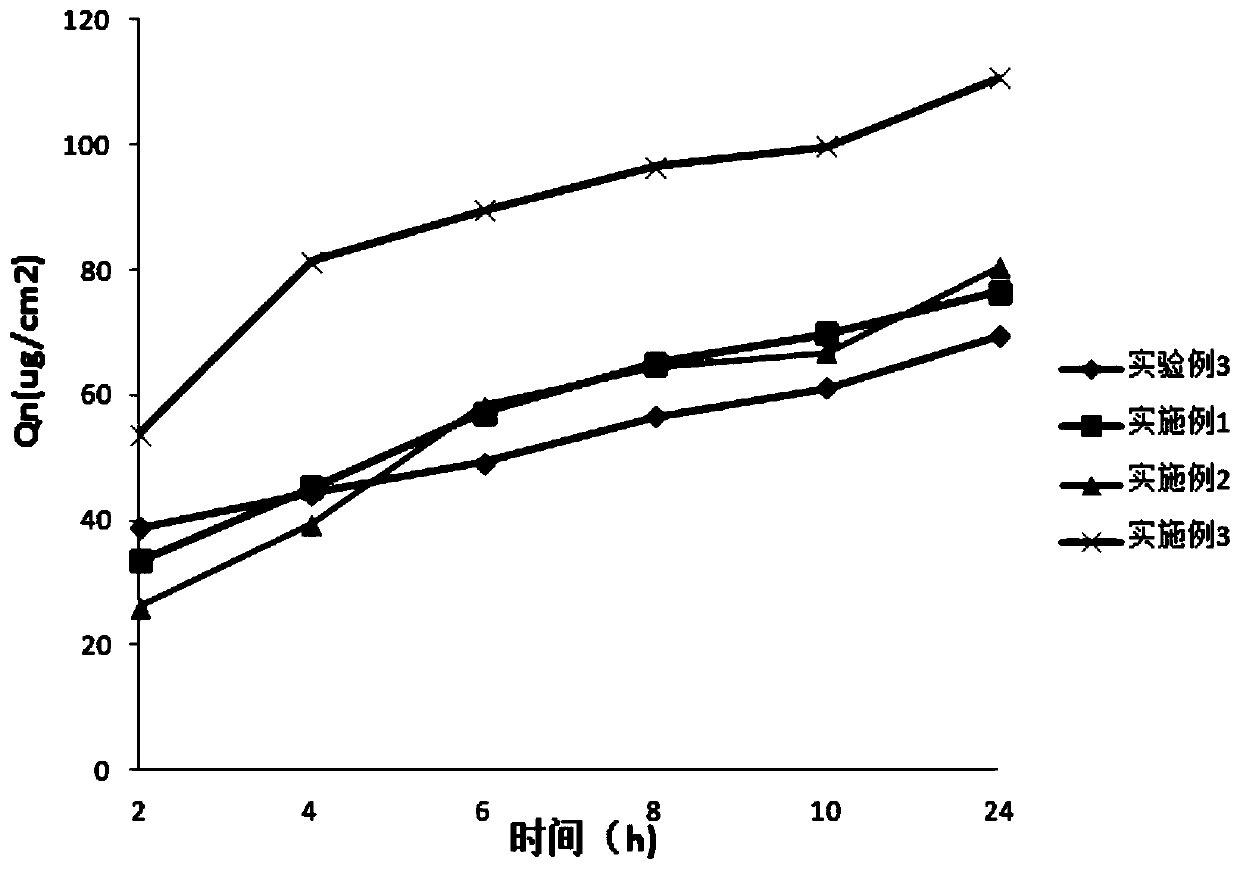

Embodiment 1

[0037] A preparation method for a seaweed anti-inflammatory extract applied to cosmetics, comprising the steps of:

[0038] (1) Water extraction method to extract kelp crude polysaccharide: 100 mesh desalted kelp dry powder was soaked in water, the mass ratio of kelp dry powder to water was 1:30, and soaked for 16 hours; after soaking, the reaction system was leached in hot water at 70°C for 10 hours, Centrifuge to obtain a kelp crude polysaccharide solution; decolorize the kelp crude polysaccharide solution with a macroporous anion resin, the mass ratio of the macroporous resin to the crude polysaccharide solution is 1:200, and stir at 45°C for 1 hour for decolorization.

[0039] (2) High-voltage pulsed electric field treatment: the temperature of the sea-tangle crude polysaccharide solution obtained in step (1) is adjusted to 40 ± 1° C., and it is passed into a high-voltage pulsed electric field disposal chamber; the working conditions for high-voltage pulsed electric field t...

Embodiment 2

[0044] A preparation method for a seaweed anti-inflammatory extract applied to cosmetics, comprising the steps of:

[0045] (1) Water extraction method to extract kelp crude polysaccharide: 100 mesh desalted kelp dry powder was soaked in water, the mass ratio of kelp dry powder to water was 1:30, and soaked for 16 hours; after soaking, the reaction system was leached in hot water at 70°C for 10 hours, Centrifuge to obtain a kelp crude polysaccharide solution; decolorize the kelp crude polysaccharide solution with a macroporous anion resin, the mass ratio of the macroporous resin to the crude polysaccharide solution is 1:200, and stir at 45°C for 1 hour for decolorization.

[0046] (2) High-voltage pulsed electric field treatment: the temperature of the sea-tangle crude polysaccharide solution obtained in step (1) is adjusted to 40 ± 1° C., and it is passed into a high-voltage pulsed electric field disposal chamber; the working conditions for high-voltage pulsed electric field t...

Embodiment 3

[0051] A preparation method for a seaweed anti-inflammatory extract applied to cosmetics, comprising the steps of:

[0052] (1) Water extraction method to extract kelp crude polysaccharide: 100 mesh desalted kelp dry powder was soaked in water, the mass ratio of kelp dry powder to water was 1:30, and soaked for 16 hours; after soaking, the reaction system was leached in hot water at 70°C for 10 hours, Centrifuge to obtain a kelp crude polysaccharide solution; decolorize the kelp crude polysaccharide solution with a macroporous anion resin, the mass ratio of the macroporous resin to the crude polysaccharide solution is 1:200, and stir at 45°C for 1 hour for decolorization.

[0053] (2) High-voltage pulsed electric field treatment: adjust the temperature of the kelp crude polysaccharide solution obtained in step (1) to 40 ± 1°C, and add it to the high-voltage pulsed electric field treatment chamber; the working conditions for high-voltage pulsed electric field treatment are: elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com