Preparation method and applications of magnetic recyclable lanthanum oxycarbonate phosphorus-removal adsorbent

A technology of lanthanum oxycarbonate and phosphorus adsorbent, which is applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of difficult recycling and low adsorption capacity, and achieve short preparation cycle and high production efficiency. Simple process and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

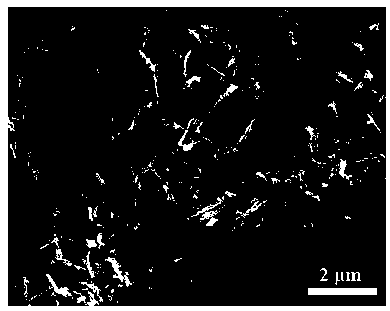

Image

Examples

Embodiment 1

[0042] In this embodiment, a magnetic recyclable lanthanum oxycarbonate dephosphorization adsorbent is prepared according to the following steps:

[0043] Step 1, the synthesis of lanthanum / iron composite metal organic framework precursor:

[0044] (1) Weigh 10 mmol (2.10 g) of trimesic acid, dissolve it in 900 ml of a water / alcohol mixed solution with a volume ratio of 1:1, and place it in a magnetic stirring constant temperature water bath at 60 °C with a constant temperature stirring bar for 0.5 h. Get liquid A;

[0045](2) Weigh 6.67 mmol (2.89 g) of lanthanum nitrate hexahydrate and 3.33 mmol (0.90 g) of ferric chloride hexahydrate, and dissolve them in 100 ml of deionized water to obtain liquid B;

[0046] (3) Under the condition of constant temperature water bath at 60 ℃, drop liquid B into liquid A drop by drop, under the action of vigorous magnetic stirring, react for 1 h, and then stand for 0.5 h to obtain light orange lanthanum / iron (2:1 , molar ratio) composite o...

Embodiment 2

[0073] The difference between this example and Example 1 is that the dosages of lanthanum nitrate hexahydrate and ferric chloride hexahydrate are both 5 mmol, and the molar ratio of metallic lanthanum to iron is 1:1.

[0074] The experimental conditions listed in Application Example 1 are used to detect its phosphorus adsorption performance, and the results show that La 2 o 2 CO 3 / γ-Fe 2 o 3 The (1:1) magnetic adsorbent also has a good removal ability for phosphate anions, and its saturated adsorption capacity can reach 102.41 mg P / g.

Embodiment 3

[0076] The difference between this example and Example 1 is that the amount of trimesic acid is 30 mmol.

[0077] The phosphorus removal performance of the magnetic adsorbent in this example was tested by isothermal adsorption batch experiments, and the results showed that its saturated adsorption capacity was 142.56 mg P / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com