A flow-type agar production line

A production line and streamlined technology, applied in the direction of transportation and packaging, packaging, packaging machines, etc., can solve problems such as low work efficiency, increase production costs, consume a lot of time and labor, and achieve high work efficiency, increase work efficiency, reduce The effect of the action steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the utility model is further described.

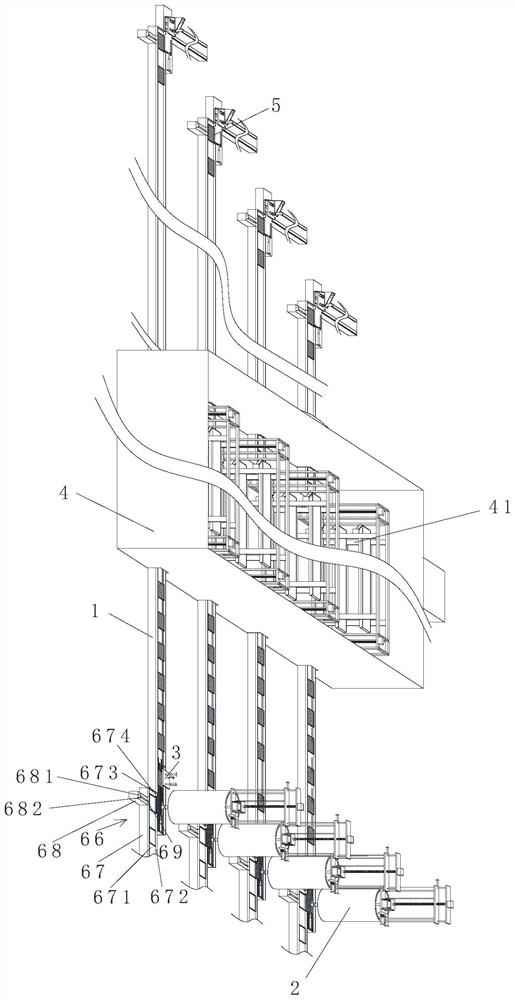

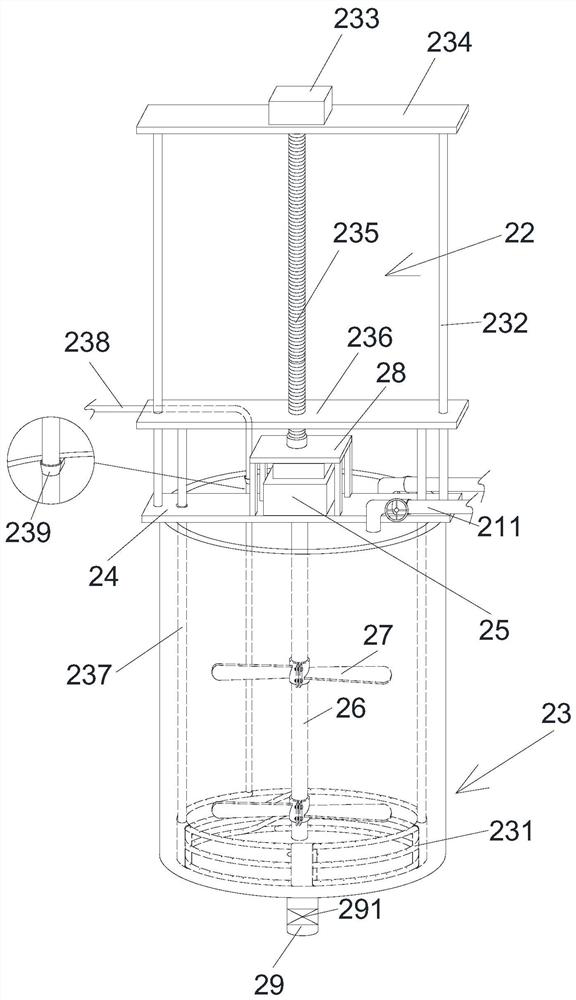

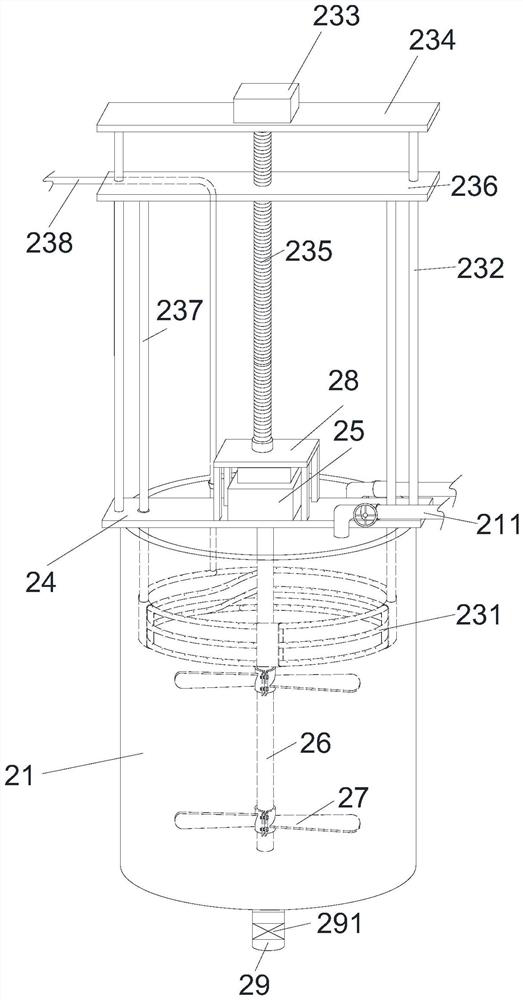

[0033] see Figure 1 to Figure 15 As shown, the present invention provides an embodiment: a flow-through agar production line, comprising a plurality of agar production lines 1, on the agar production line 1, from right to left, there are successively provided with the Jiangli that is used to cook the Jiangli vegetable into jelly Vegetable cooking glue device 2, agar squeeze water filter device for squeezing and filtering the agar tray 3, condensation chamber for cooling and solidifying the agar on the agar tray after extrusion, and cutting the cooled agar into pieces Agar orientation adjustable automatic cutting device 5; the Jiangli vegetable cooking gelatin device 2 is arranged above the agar squeeze water filter device 3, and the agar squeeze water filter device 3 is connected to the agar squeeze water filter device 3 through the first chain conveyor belt The condensation cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com