A kind of two-component terminal silyl group polyether modified sealant and its preparation method

A silyl-terminated polyether and sealant technology, which is applied in the field of sealants, can solve the problems of poor storage stability of sealants, weak shear strength of substrates, and slow curing in deep layers, and achieve short positioning time, fast curing, and long shelf life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of a two-component silyl-terminated polyether modified sealant, comprising:

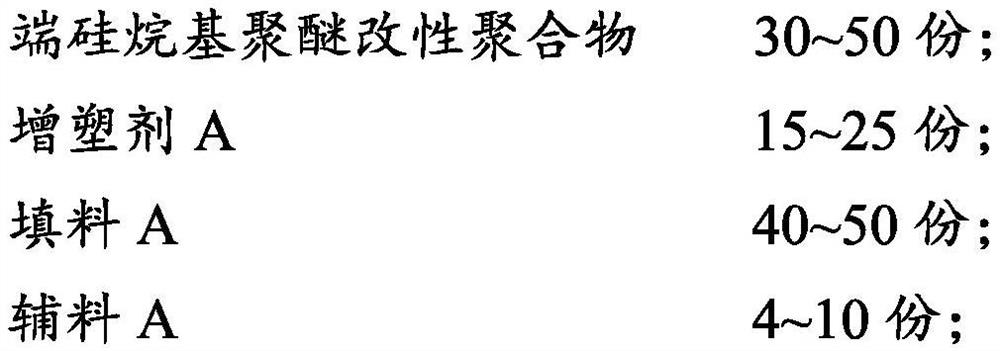

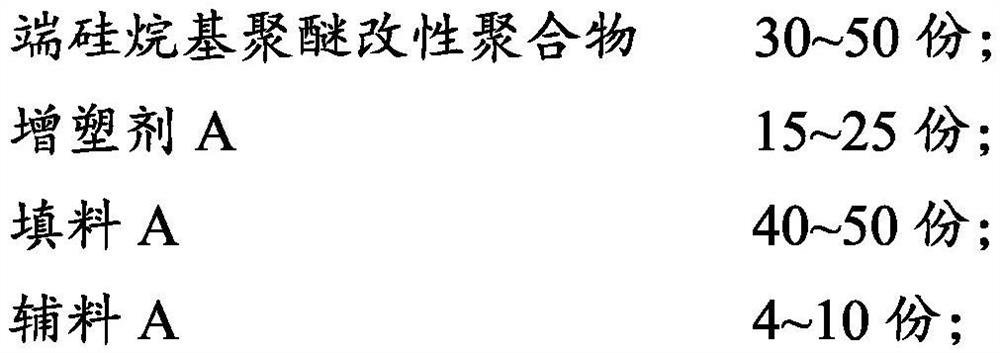

[0044] Component A is obtained by mixing 30-50 parts by weight of a silyl-terminated polyether-modified polymer, 15-25 parts by weight of a plasticizer A, 40-50 parts by weight of a filler A, and 4-10 parts by weight of an auxiliary material A;

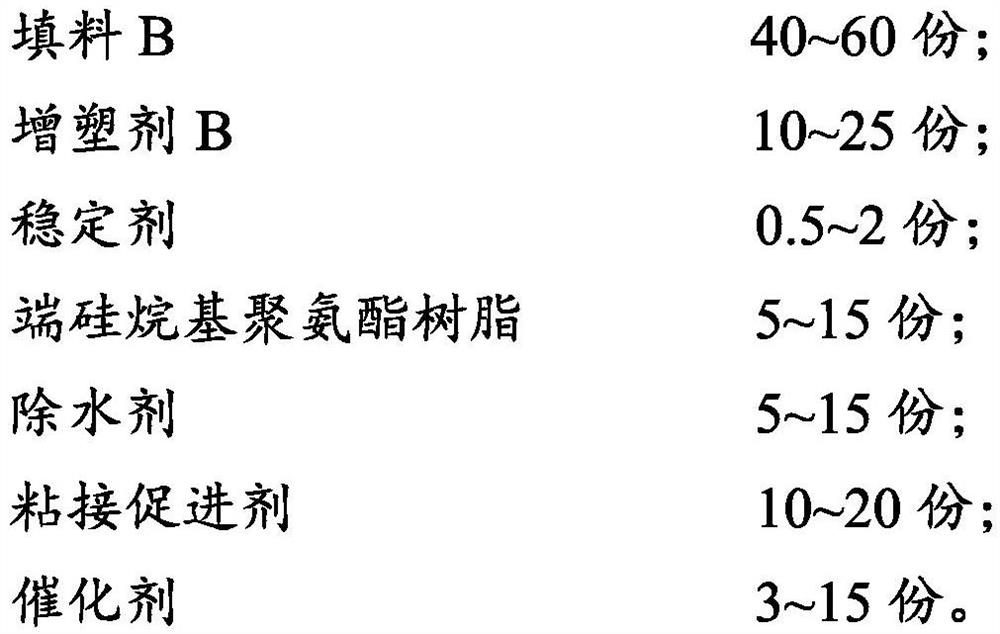

[0045] 40-60 parts by weight of filler B, 10-25 parts by weight of plasticizer B, 0.5-2 parts by weight of stabilizer, 5-15 parts by weight of terminal silane-based polyurethane resin, 5-15 parts by weight of water-removing agent, 10-20 parts by weight The adhesion promoter and 3-15 weight parts of the catalyst are mixed and stirred to obtain the component B.

[0046] According to the present invention, the present invention mixes and stirs 30-50 parts by weight of terminal silane-based polyether modified polymer, 15-25 parts by weight of plasticizer A, 40-50 parts by weight of filler A, and 4-1...

Embodiment 1

[0051] Component A: 40 parts of silyl-terminated polyether modified polymer 1 (25 parts of S303H of Zhongyuan Chemical, 15 parts of SAT720), 20 parts of plasticizer DIDP, 45 parts of filler A (light 40 parts of high quality calcium carbonate, 5 parts of heavy calcium carbonate), 2.5 parts of reinforcing filler (hydrophilic fumed silica), 2 parts of colored filler (carbon black), 1.5 parts of ultraviolet light absorber (BASF's 329) added Put it into a double-planetary stirred tank, stir for 1 hour under the conditions of a vacuum greater than 0.09MPa and a stirring speed greater than 25rpm / min, control the water content within the range of 1000-2000ppm, and put the material into a 300ml A tube to prepare the A component.

[0052] Component B: Add 50 parts of filler B (40 parts of 0.6μm light calcium carbonate, 10 parts of heavy calcium carbonate), 15 parts of plasticizer DIDP, and 1 part of heat stabilizer (BASF 1010) into the double planetary stirring tank , dehydration for 2 ...

Embodiment 2

[0055] Component A: 40 parts of terminal silyl polyether modified polymer 1 (40 parts of SAX400 of Zhongyuan Chemical), 20 parts of plasticizer DIDP, 45 parts of filler A (light calcium carbonate 40 parts of 0.6 μm particle size Parts, 5 parts of heavy calcium carbonate), 2.5 parts of reinforcing filler (hydrophilic fumed silica), 2 parts of colored filler (carbon black), 1.5 parts of ultraviolet light absorber (BASF's 329) are added to the double planetary stirring In the kettle, stir for 1 hour under the conditions of a vacuum degree greater than 0.09MPa and a stirring speed greater than 25rpm / min, control the water content within the range of 1000-2000ppm, and put the material into a 300ml A tube to prepare the A component

[0056] Component B: Add 50 parts of filler B (40 parts of 0.6μm light calcium carbonate, 10 parts of heavy calcium carbonate), 15 parts of plasticizer DIDP, and 1 part of heat stabilizer (BASF 1010) into the double planetary stirring tank , dehydration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com