Continuous pretreatment system and process for pirimiphos-methyl wastewater

A pretreatment technology of pirimiphos-methyl, applied in water/sewage treatment, natural water treatment, neutralized water/sewage treatment, etc., can solve the problems of lack of mature and effective industrialized treatment methods, low current efficiency, long mass transfer distance, etc. problems, to achieve the effect of easy engineering promotion and application, low operating cost and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

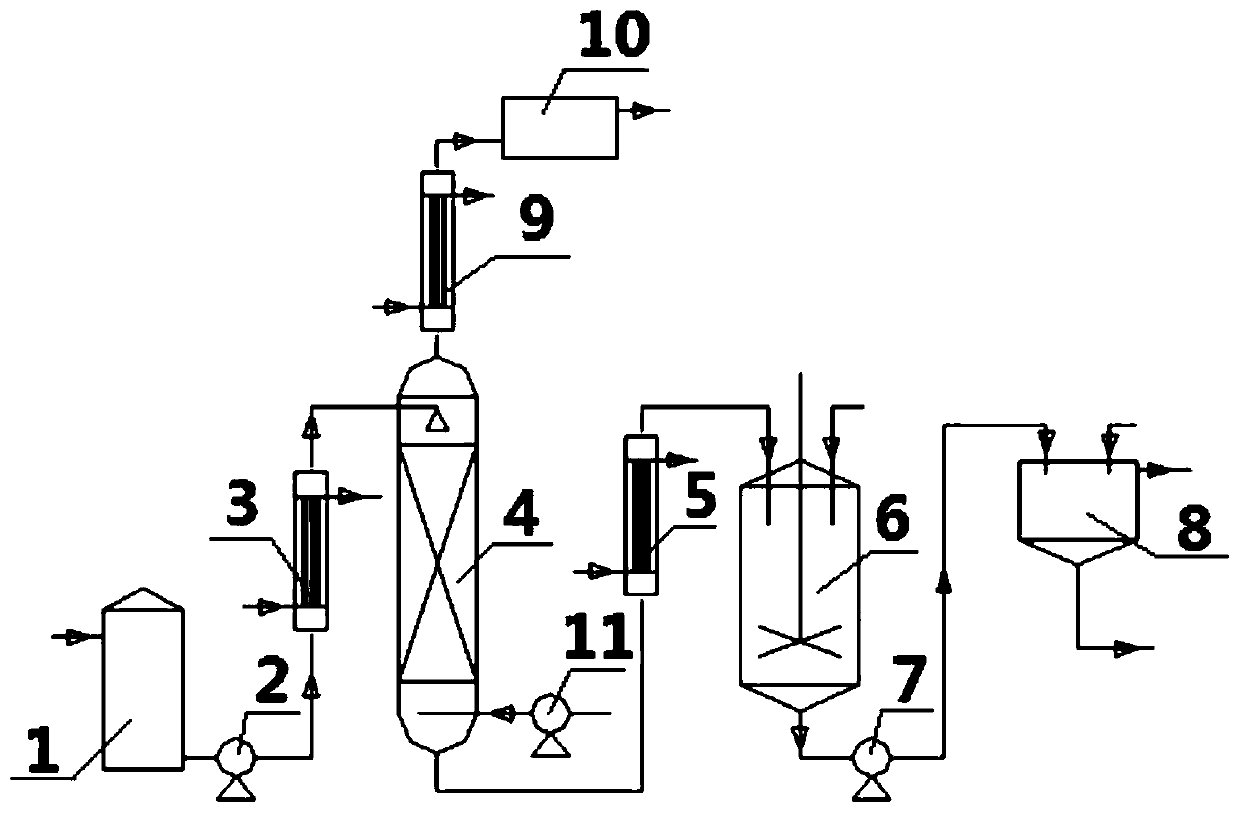

[0041] Such as figure 1 As shown, a continuous pretreatment system for pirimiphos-methyl wastewater includes a sequentially connected wastewater storage tank 1, a first water pump 2, a heater 3, a three-dimensional electrocatalytic oxidation stripping tower 4, a first cooler 5, The neutralization kettle 6, the second water pump 7, and the settling tank 8, wherein the three-dimensional electrocatalytic oxidation stripping tower 4 includes a stripping tower, and a three-dimensional electrocatalytic oxidation device is arranged in the stripping tower. In this embodiment, the effective height of the stripping tower is 6500 mm, and the tower diameter is 600 mm.

[0042] In this example, the three-dimensional electrocatalytic oxidation device is a cylindrical structure, with an IrO-RuO / Ti rod as the anode in the center, and a stainless steel plate as the cathode around it, where the IrO 2 -RuO 2 The diameter of the / Ti rod is 100mm; the diameter of the cathode is 400mm, and the ef...

Embodiment 2

[0049] A kind of continuous pretreatment process of pirimiphos-methyl wastewater, this continuous pretreatment process is to adopt the continuous pretreatment system in embodiment 1 to carry out pretreatment to pirimiphos-methyl wastewater, comprising the following steps:

[0050] (1) Oxidation stripping

[0051] (1.1) The pirimiphos-methyl wastewater of a pesticide factory in Changde was stored in a wastewater storage tank, wherein the discharge of pirimiphos-methyl wastewater in the pesticide factory was 48 tons / day.

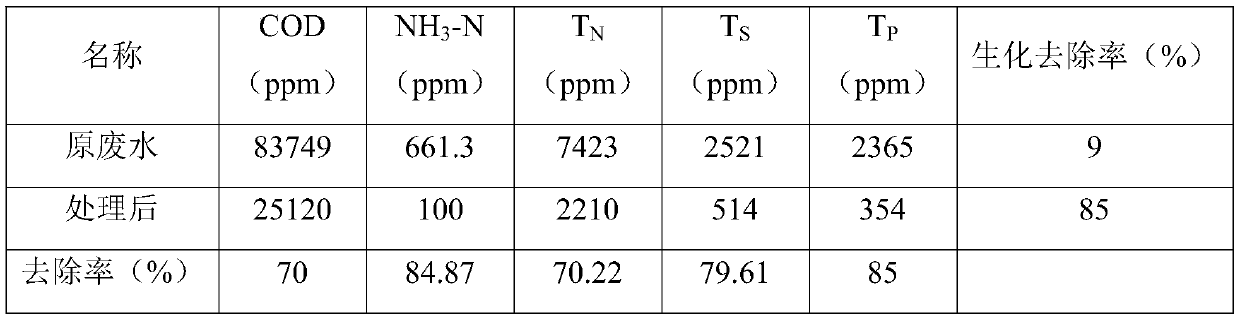

[0052] (1.2) Use the first water pump to send the pirimiphos-methyl wastewater in the wastewater storage tank (the pH of the wastewater is 7-8, and the water quality is as shown in Table 1) into the heater and heated to 65°C.

[0053] (1.3) According to the water flow rate of 2m 3 / h, the heated waste water in step (1.2) is sent into the three-dimensional electrocatalytic oxidation stripping tower from the upper part of the tower, and the current density is k...

Embodiment 3

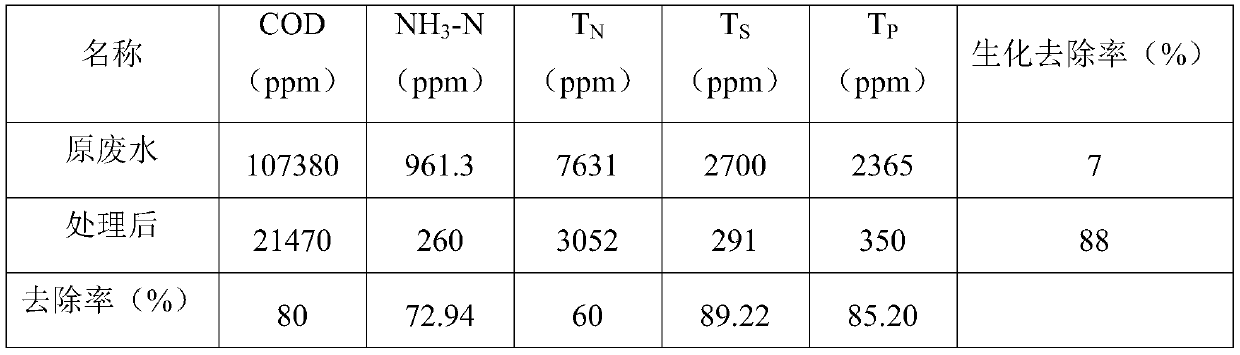

[0061] A continuous pretreatment system for pirimiphos-methyl wastewater. Compared with the continuous pretreatment system in Example 1, the only difference is that the filling material between the anode and cathode of the three-dimensional electrocatalytic oxidation device in Example 3 is different.

[0062] In Example 3, the preparation method of the electrocatalytic oxidation filler filled between the anode and the cathode of the three-dimensional electrocatalytic oxidation device comprises the following steps:

[0063] S1. Weigh 12kg of clay, 6kg of diatomite and 2kg of bentonite, add 10g of water glass with a mass concentration of 30% to make a spherical solid with a particle diameter of 50mm, and dry it at 105°C to obtain a catalyst carrier.

[0064] S2, put the catalyst carrier obtained in step S1 into a mixed solution of 6.9kg copper acetate and manganese acetate (this mixed solution is made by dissolving 492g manganese acetate and 200g copper acetate in water, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com