Method and device for continuously treating heavy metal polluted sludge

A technology for heavy metals and sludge, applied in water pollutants, sludge treatment, special treatment targets, etc., can solve the problems of long time period, high cost, and excessive composting treatment, and achieve harmless treatment and advanced treatment. , The effect of reducing sludge odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

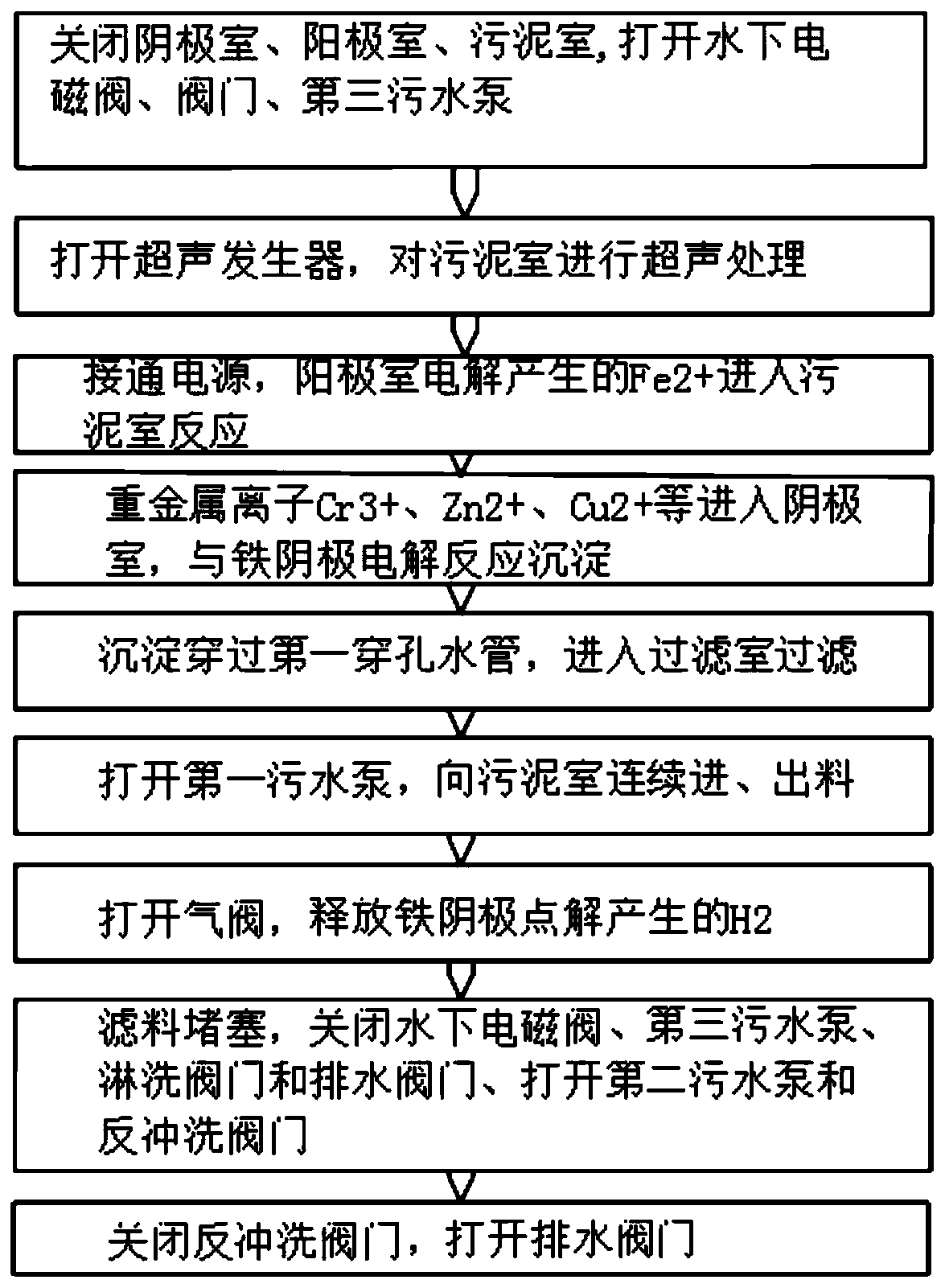

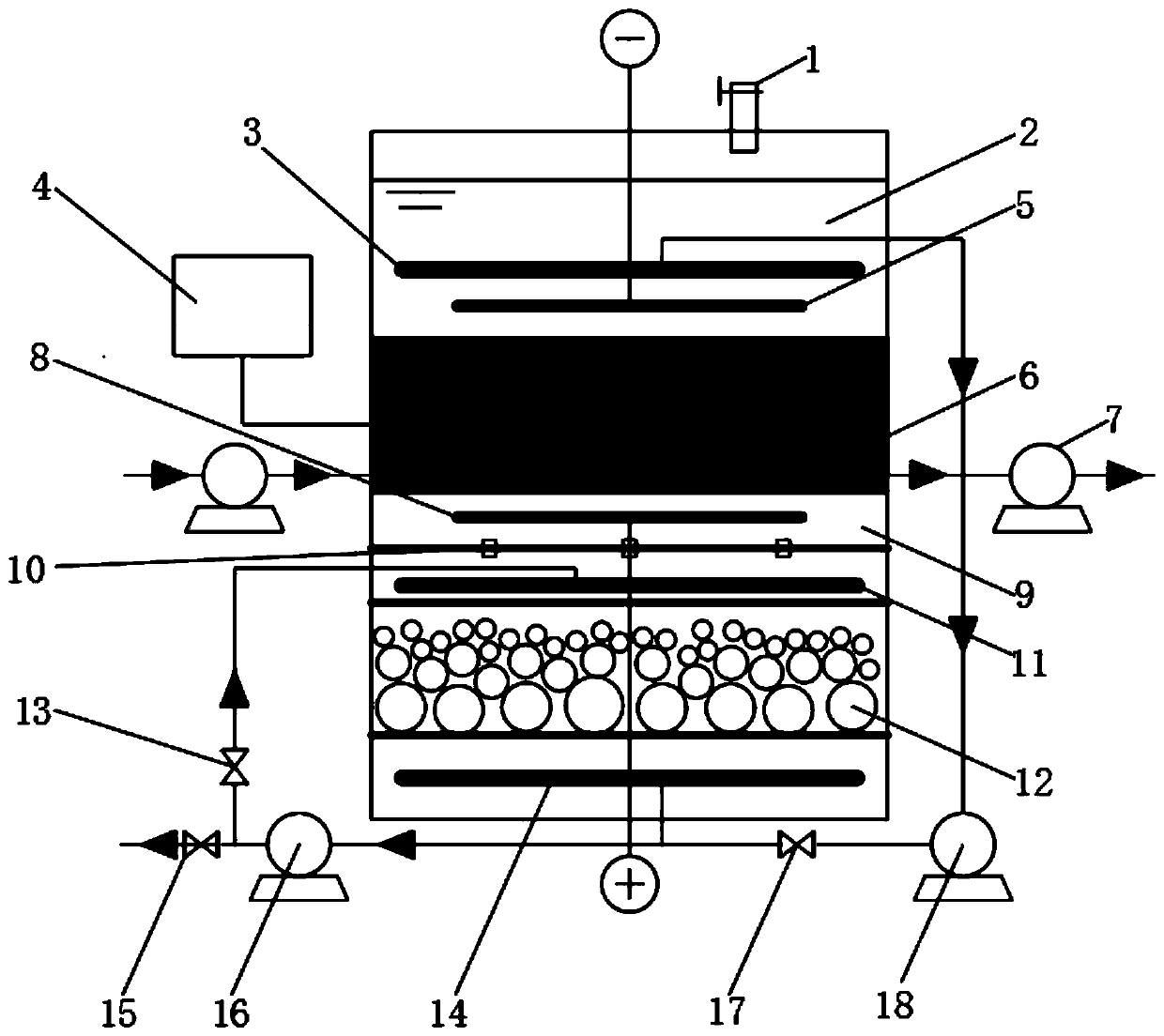

[0039] see figure 1 , the present invention provides a technical solution: the method for continuously treating heavy metal contaminated sludge comprises the following steps:

[0040] S1: Seal the cathode chamber 2, the anode chamber 9 and the sludge chamber 6, close the backwashing device, open the underwater solenoid valve 10, the valve 17 and the third sewage pump 18, so that the system aqueous solution passes through the filter layer 12 and the anode chamber in sequence 9. The sludge chamber 6 and the cathode chamber 2 are circulated from the first perforated water pipe 3 to the filter layer 12 through the third sewage pump 18 to realize continuous sludge washing;

[0041] S2: Turn on the ultrasonic generator 4, perform low-intensity ultrasonic treatment on the sludge in the sludge chamber 6, break up the sludge flocs, and release the heavy metal ions wrapped in the sludge such as Cu 2+ , Zn 2+ ;

[0042] S3: Turn on the power, in the anode chamber 9, the iron anode 8 e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com