High-protein low-carbon water fat-reducing biscuit and preparation method thereof

A technology of carbohydrate-reducing biscuits and carbohydrate-reducing fat, which is applied in baking, baked goods, food science and other directions, can solve the problems of neglecting nutritional needs, declining basal metabolism of the human body, and simple nutritional structure, so as to reduce intake and absorption, increase Serum HDL-C level and the effect of meeting trace element requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

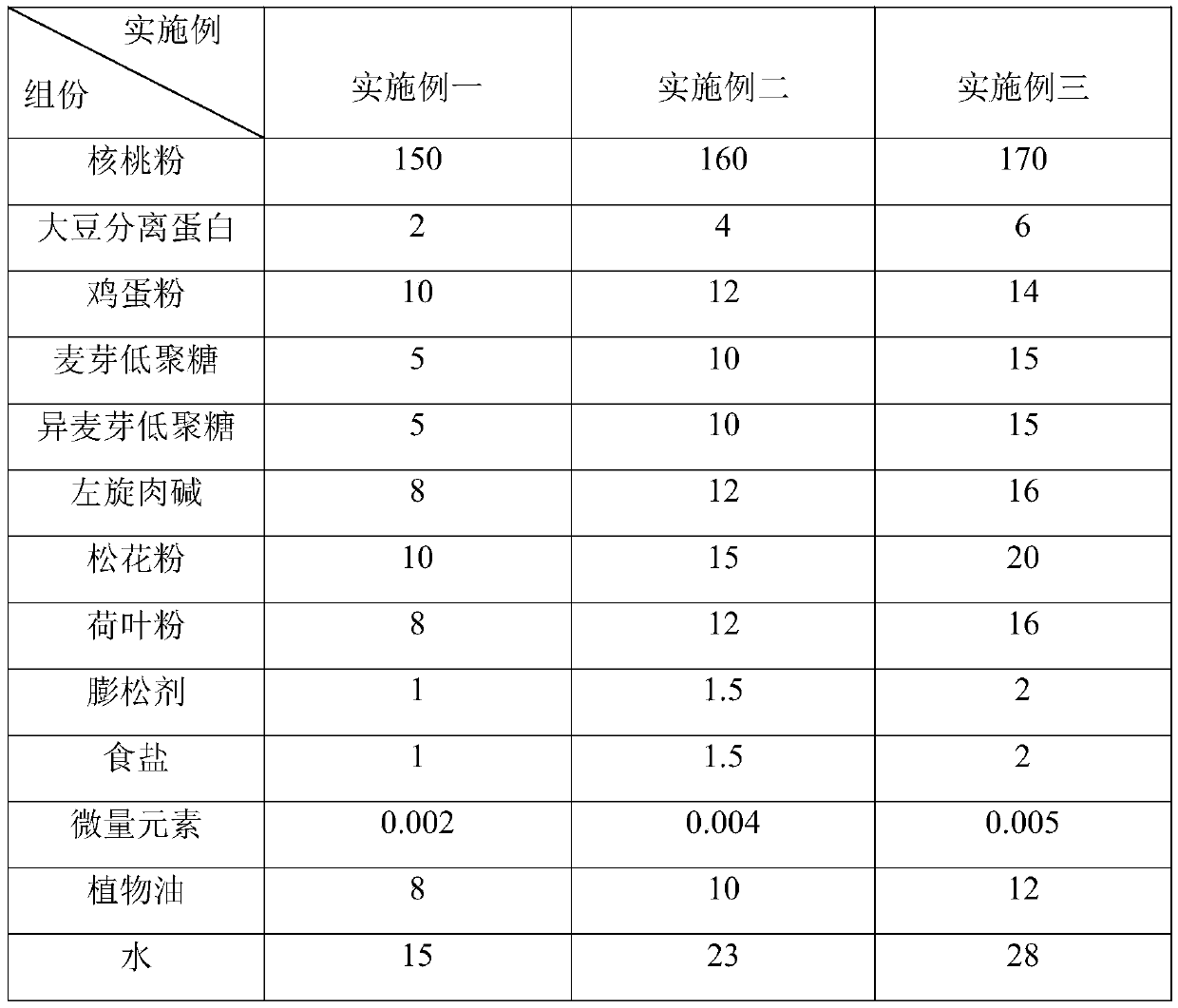

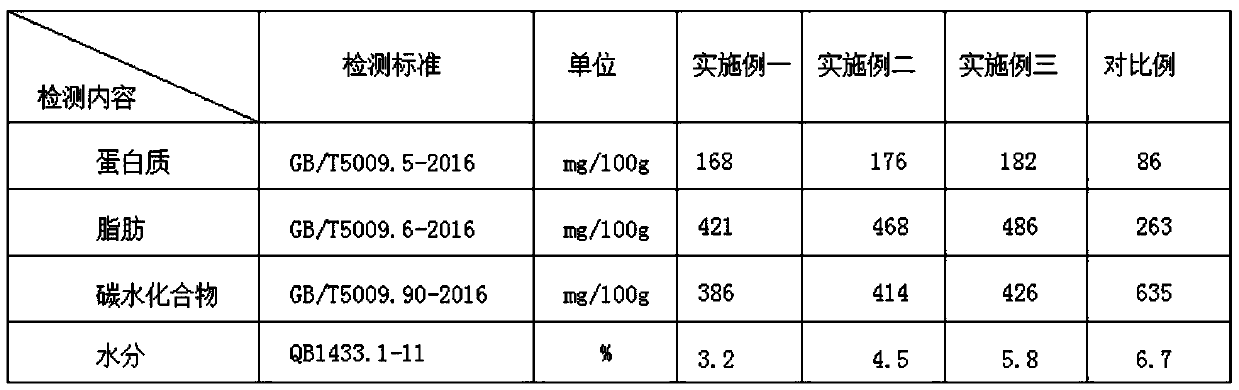

Embodiment 1

[0036] A high-protein, low-carbohydrate and fat-reducing biscuit is composed of the following ingredients in parts by weight: 150 parts of walnut powder, 2 parts of soybean protein isolate, 10 parts of egg powder, 5 parts of maltooligosaccharide, 5 parts of isomaltooligosaccharide, 8 parts of L-carnitine, 10 parts of pine pollen, 8 parts of lotus leaf powder, 1 part of leavening agent, 1 part of table salt, 0.002 parts of trace elements, 8 parts of vegetable oil, and 15 parts of water.

[0037] Among them, the pine pollen is broken wall pine pollen processed by superfine grinding, and its wall breaking rate is greater than 90%. The lotus leaf powder is made by selecting, crushing and passing through a 100-mesh sieve using lotus leaves as raw materials.

[0038] Wherein, the leavening agent is formed by mixing 0.5 parts each of sodium bicarbonate and yeast powder.

[0039] Among them, the trace elements are made by mixing ferrous lactate, vitamin B and vitamin D according to th...

Embodiment 2

[0051] A high-protein, low-carbohydrate and fat-reducing biscuit is composed of the following ingredients in parts by weight: 160 parts of walnut powder, 4 parts of soybean protein isolate, 12 parts of egg powder, 10 parts of maltooligosaccharide, 10 parts of isomaltooligosaccharide, 12 parts of L-carnitine, 15 parts of pine pollen, 12 parts of lotus leaf powder, 1.5 parts of leavening agent, 1.5 parts of table salt, 0.004 parts of trace elements, 10 parts of vegetable oil, and 23 parts of water.

[0052] Among them, the pine pollen is broken wall pine pollen processed by superfine grinding, and its wall breaking rate is greater than 90%. The lotus leaf powder is made by selecting, crushing and passing through a 100-mesh sieve using lotus leaves as raw materials.

[0053] Wherein, the leavening agent is formed by mixing 0.75 parts of sodium bicarbonate and yeast powder respectively.

[0054] Among them, the trace elements are made by mixing ferrous lactate, vitamin B and vitam...

Embodiment 3

[0066] A high-protein, low-carbohydrate and fat-reducing biscuit is composed of the following ingredients in parts by weight: 170 parts of walnut powder, 6 parts of soybean protein isolate, 14 parts of egg powder, 15 parts of maltooligosaccharide, 15 parts of isomaltooligosaccharide, 16 parts of L-carnitine, 20 parts of pine pollen, 16 parts of lotus leaf powder, 2 parts of leavening agent, 2 parts of table salt, 0.005 parts of trace elements, 12 parts of vegetable oil, and 28 parts of water.

[0067] Among them, the pine pollen is broken wall pine pollen processed by superfine grinding, and its wall breaking rate is greater than 90%. The lotus leaf powder is made by selecting, crushing and passing through a 100-mesh sieve using lotus leaves as raw materials.

[0068] Wherein, the leavening agent is formed by mixing 1.0 parts each of sodium bicarbonate and yeast powder.

[0069] Among them, the trace elements are made by mixing ferrous lactate, vitamin B and vitamin D accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com