On-site repair method of high temperature radar and infrared compatible stealth coating

A repair method and high-temperature technology, applied in coatings, devices for applying liquid to surfaces, pre-treatment surfaces, etc., can solve the problems of damaged parts that do not have the conditions for dismantling and returning to the factory, cannot be used in high-temperature environments, and require sinterability. , to achieve the effect of simple and portable tools and heating equipment, shortened sintering time, and reduced sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

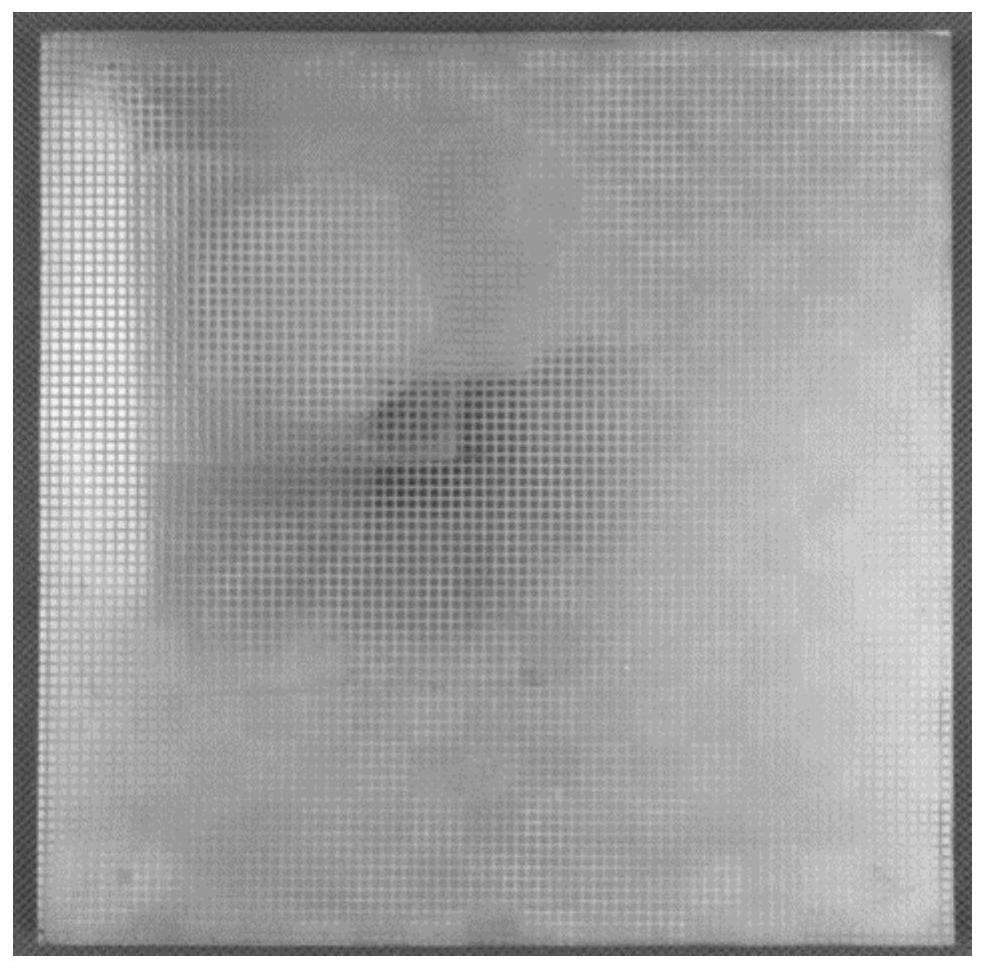

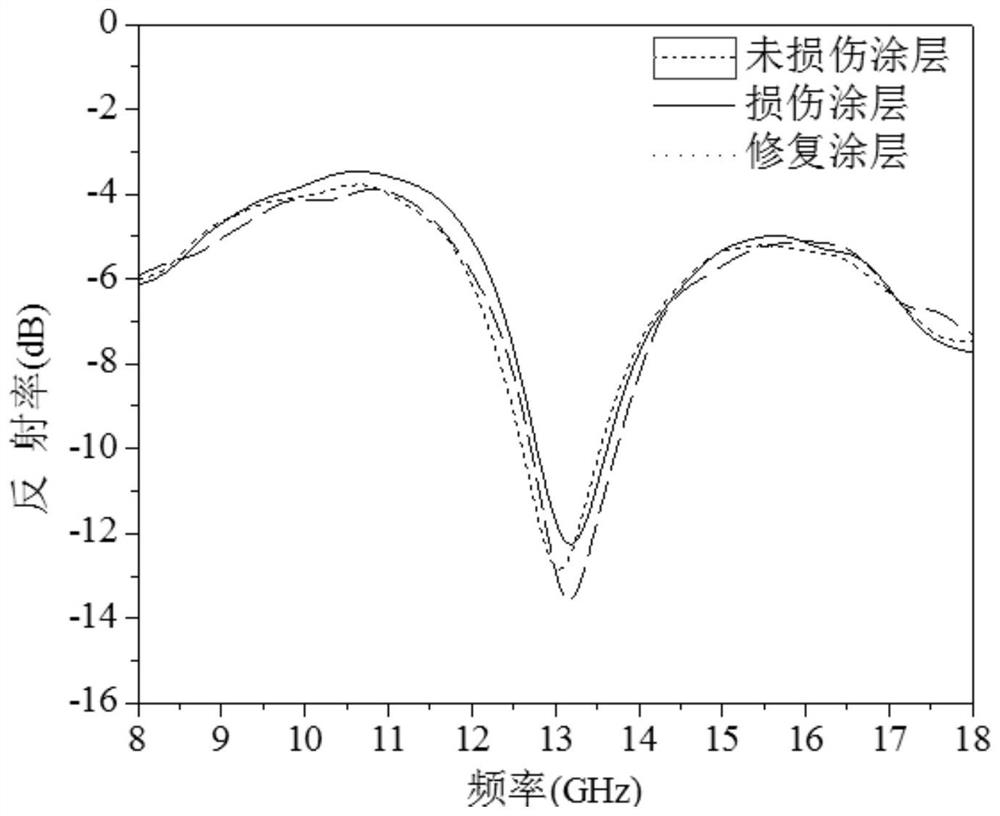

[0042] This embodiment provides a high-temperature radar infrared-compatible stealth coating on-site repair method for the damage of the patch conductor type high-temperature periodic structural layer in the high-temperature radar and infrared compatible stealth coating, and the size of the damaged area is 5cm*6cm, including the following steps:

[0043] (1) Prepare conductor paint: described conductor paint is made up of following mass percentage raw material: 70% silver powder, 10% glass powder, surplus is organic vehicle, and glass powder is made up of following mass percentage component: 58% Bi 2 o 3 , 25% B 2 o 3 , 13% Sb 2 o 3 and 4% SiO 2 ; The organic vehicle is composed of 85% tributyl citrate, 6% nitrocellulose and 9% lecithin by mass fraction;

[0044] (2) Clean up the damaged area, and use adhesive tape to cover the surrounding complete coating to delineate the repair area;

[0045] (3) Apply the conductive paint obtained in step (1) to the repaired area desc...

Embodiment 2

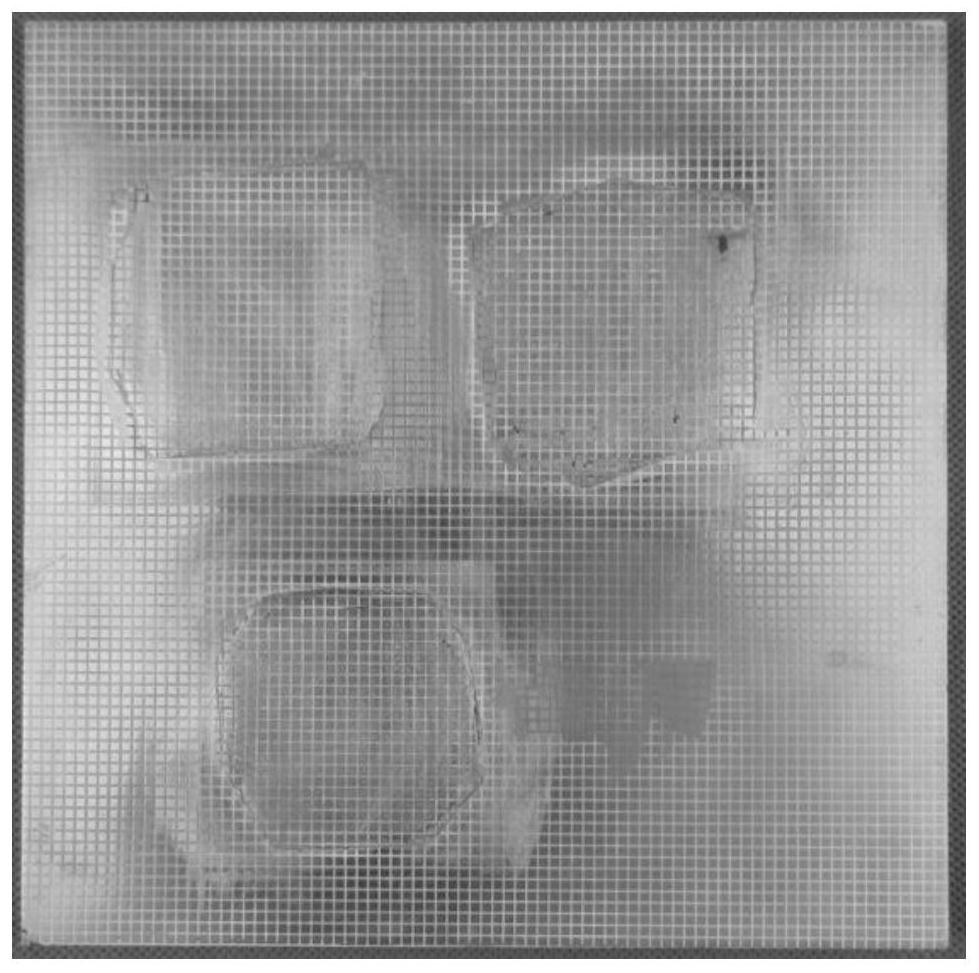

[0048] In this embodiment, the ceramic bottom layer, the chip resistance type high temperature periodic structure layer, the isolation layer and the chip conductor type high temperature periodic structure layer in the high temperature radar and infrared compatible stealth coating are all damaged, three damages, each damage area is about 5cm*6cm, the area where the three damages are located is 14cm*12cm, and the damage depth of the ceramic bottom layer is 0.5mm. It provides a high-temperature radar infrared compatible stealth coating on-site repair method, including ceramic bottom repair, chip resistance type high-temperature periodic structure Layer repair, isolation layer repair and patch conductor type high temperature period structure layer repair.

[0049] 2.1 Ceramic bottom repair method

[0050] (1) Prepare high-temperature ceramic glue B. High-temperature ceramic glue B is composed of the following raw materials in parts by mass: 13 parts of aluminum dihydrogen phosphat...

Embodiment 3

[0069] In this embodiment, the ceramic bottom layer, the chip resistance type high temperature periodic structure layer, the isolation layer and the chip conductor type high temperature periodic structure layer in the high temperature radar and infrared compatible stealth coating are all damaged, two damages, and the areas where the two damages are located The range is 12cm*10cm, and the damage depth of the ceramic bottom layer is 0.7mm. It provides a high-temperature radar infrared compatible stealth coating on-site repair method, including ceramic bottom repair, chip resistance type high temperature periodic structural layer repair, isolation layer repair and patch guide Body shape high temperature cycle structural layer repair.

[0070] 3.1 Ceramic bottom repair method

[0071] (1) Prepare high-temperature ceramic glue B. High-temperature ceramic glue B is composed of the following raw materials in parts by mass: 15 parts of aluminum dihydrogen phosphate, 48 parts of alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com