A kind of ternary light-resistant liquid crystal copolymer containing imidoxazole structure and its preparation and application

A technology containing imoxazole and copolymers, applied in the direction of conjugated synthetic polymer rayon, liquid crystal materials, single-component synthetic polymer rayon, etc., can solve the problems of slow development, low heat resistance temperature PBO, and low strength and other problems, to achieve the effect of short polymerization time, high heat resistance and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

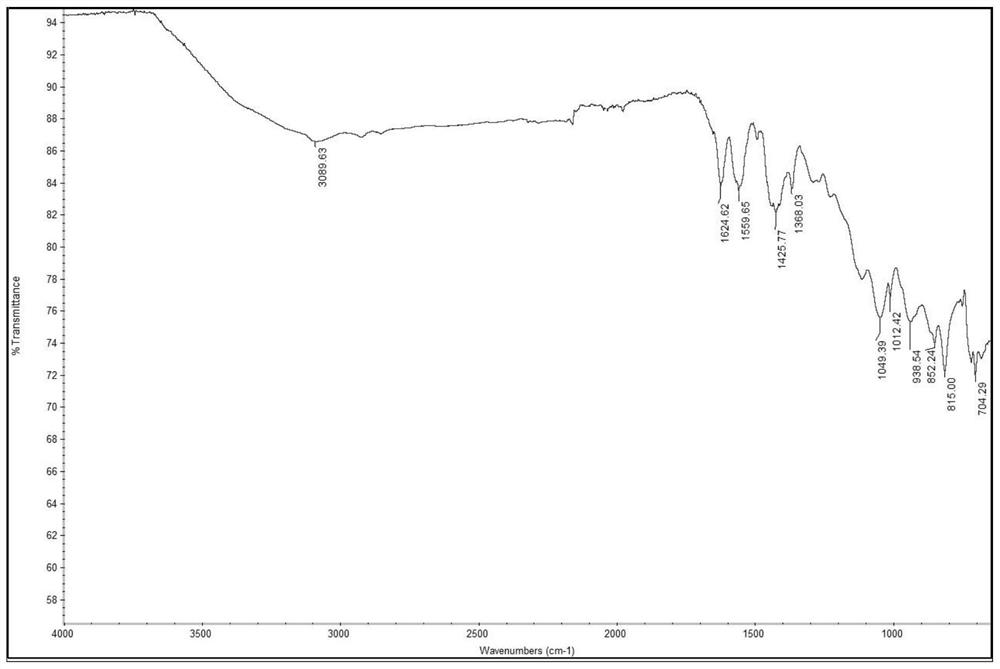

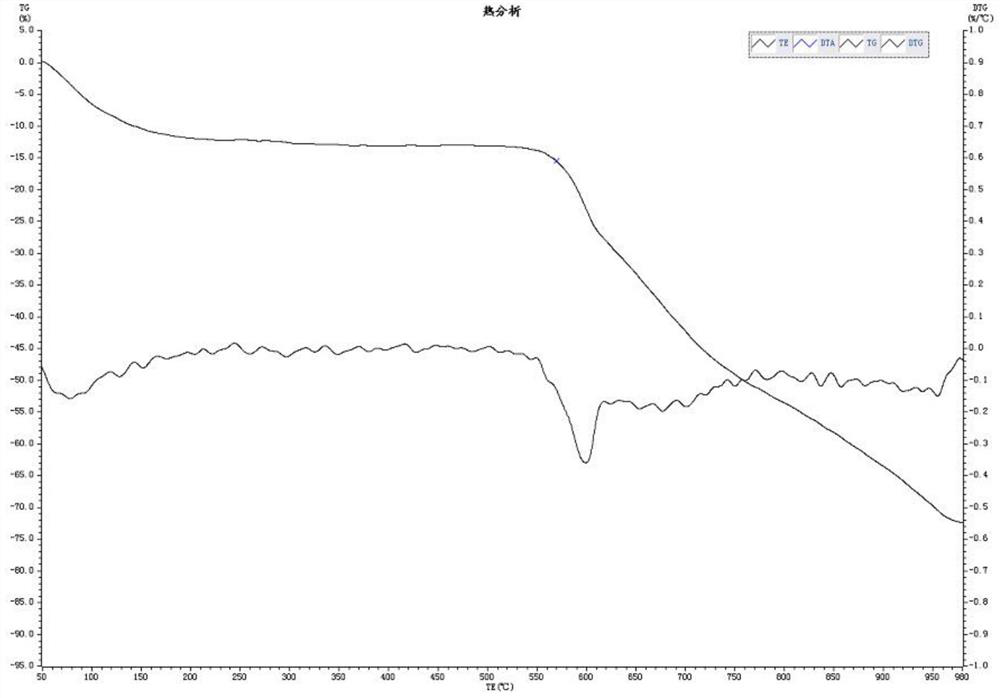

[0074] Example 1 O 4 -PBO-ABPBI (poly-2,5-benzoxazole-p-phenylenebenzobisoxazole-benzimidazole) and its monofilament fibers

[0075]

[0076] Sequentially add P into the glass polymerization reaction column 2 o 5 Mass concentration is 20.0g of polyphosphoric acid (PPA) of 85.65%, turn on spiral stirring, and heat up 150 ℃ and control the rotating speed stirring of 350r / min, pass N 2 Slowly add 5.0266g of a mixture of three AB-type monomers (AHBA 0.860g, ABAA 1.613g, DABA 2.563g, (mol ratio 1:1:3, mass ratio 0.17:0.32:0.51) under protection for 3min, and add for 1h Stir and heat up to 168°C to show fluorescence (liquid crystal state after 20 minutes), finally control the temperature between 170-180°C, and then polymerize for 1 hour to form filaments, until the speed drops significantly to 200r / min or below, the polymerization reaction is over, stop stirring .O 4 -PBO-ABPBI ternary liquid crystal copolymer (O 4 PBO-co-PBO-co-ABPBI, modified chain link n / (n+m+k)=20%, k / (n...

Embodiment 2

[0088] Example 2 O 4 -HPBO-ABPBI (poly-2,5-benzoxazole-hydroxyp-phenylenebenzobisoxazole-benzimidazole) and its monofilament fibers

[0089]

[0090] A) 10% monooxazole-26% HPBO modified ABPBI

[0091] Sequentially add P into the glass polymerization reaction column 2 o 5 Mass concentration is 88.43% polyphosphoric acid (PPA) 23.5g (18.5g85.3%PPA, 5.0gP 2 o 5 ), turn on the spiral stirring, and raise the temperature to 120°C to control the stirring at a speed of 350r / min, pass N 2 Slowly add 5.615g of a mixture of a compound salt and two AB-type monomers (AHBA 0.459g, HD2.417g, DABA 2.739g, mol ratio 0.5:1.25:3, mass ratio 0.08:0.43:0.49) under protection, and add Stir for 30 minutes and heat up to 150°C to appear yellow-green fluorescence (liquid crystal state after 20 minutes). Finally, control the temperature between 150-180°C and polymerize for another 30 minutes to form a filament until the speed drops significantly to 200r / min or below. When finished, stop stirr...

Embodiment 3

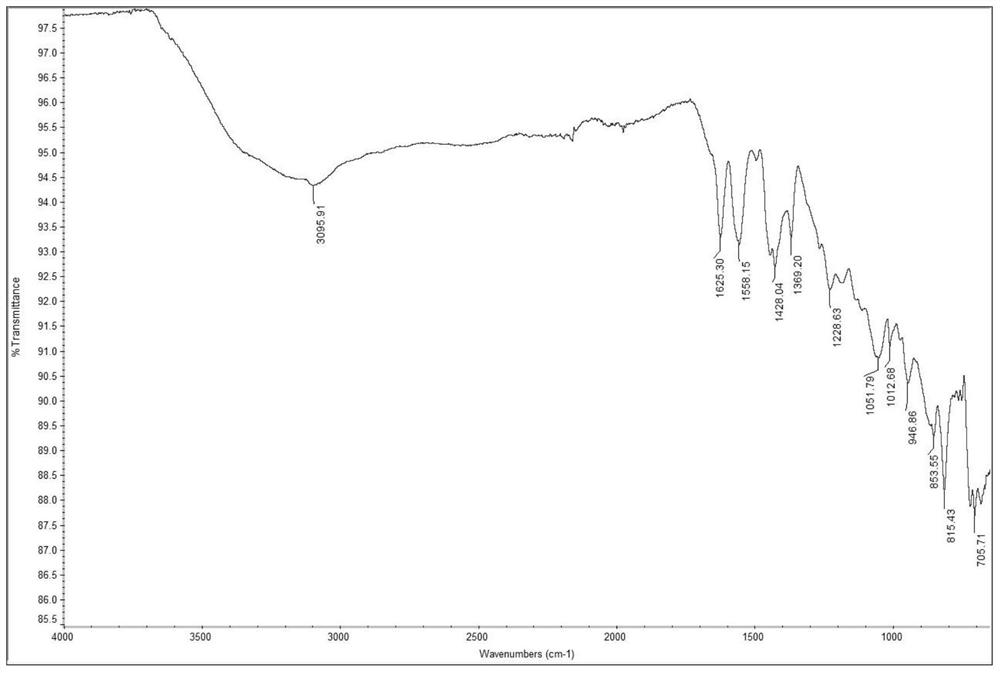

[0094] Example 3 O 4 -PBI-ABPBI (poly-2,5-benzoxazole-p-phenylenebenzodiimidazole-benzimidazole) and its monofilament fibers

[0095]

[0096] Sequentially add P into the glass polymerization reaction column 2 o 5 Mass concentration is 85.3% polyphosphoric acid (PPA) 18.0g, P 2 o 5 3.4g, turn on the spiral stirring, and raise the temperature to 120°C and control the stirring speed of 350r / min, pass N 2 Slowly add 4.866g of a mixture of two AB-type monomers and a compound salt monomer (AHBA 1.633g, TATAB 1.613g, DABA1.62g, mol ratio 1:0.5:1, mass ratio 0.336:0.331:0.333) under protection for 3 minutes After adding, stir for 1 hour and heat up to 164°C to appear gray brown fluorescence (liquid crystal state after 15 minutes), and finally control the temperature between 165-170°C and polymerize for another 20 minutes until the speed drops significantly to 200r / min or below. For the end of the polymerization reaction, stop stirring. Get O 4 -PBI-ABPBI ternary liquid crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com