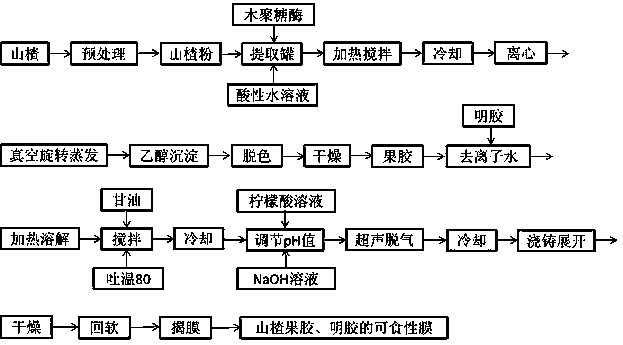

Method for preparing edible film rich in hawthorn pectin and gelatin

A technology of pectin and hawthorn, which is applied in flexible covering, packaging, wrapping paper, etc., can solve the problems of hidden dangers of food safety and environmental pollution, and achieve the effect of accelerating dissolution speed, low cost and good film-forming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Put 50 g of hawthorn powder in the extraction container, add 1000 mL of acidic deionized water with a pH value of 4 and xylanase of 1% of the mass of hawthorn powder; adjust the temperature on the magnetic stirrer to 50 °C, and the rotation speed to 200 r / min, extraction for 1 h. Cool to room temperature, set the speed of the centrifuge to 10000 r / min, and centrifuge for 5 minutes. The supernatant is rotatively evaporated at a temperature of 50 °C, a vacuum of -0.09 MPa, and a speed of 60 r / min to concentrate The volume of the liquid is 50% of the volume of the original extract. After cooling at room temperature, use 2 times the volume of the concentrated solution to precipitate the pectin extract to collect the pectin precipitate; then add 2 times the volume of ethanol to the pectin precipitate Rinse and decolorize 3 times to obtain wet pectin; dry the wet pectin with hot air at 50°C for 24 hours to obtain hawthorn pectin.

[0023] Add 2 g of hawthorn pectin and 6 g ...

Embodiment 2

[0026] Put 200 g of hawthorn powder in an extraction container, add 1000 mL of acidic deionized water with a pH value of 7 and xylanase of 3% raw material mass of hawthorn powder. Adjust the temperature to 50 °C, the rotation speed to 200 r / min, and extract for 1 h. Cool to room temperature, set the speed of the centrifuge to 10000 r / min, centrifuge for 5 minutes, and rotate the supernatant at a temperature of 50 °C, a vacuum of -0.09 MPa, and a speed of 60 r / min to concentrate The liquid volume is 50% of the original extract volume. After cooling, the pectin extract was precipitated with 2 times the volume of the concentrate, and the pectin precipitate was collected. Then add ethanol twice the volume of the pectin precipitate to rinse and decolorize the pectin precipitate 3 times to obtain wet pectin. The wet pectin was dried with hot air at 50 ℃ for 24 h to obtain hawthorn pectin.

[0027] Add 3 g of hawthorn pectin and 6 g of gelatin into 100 mL of deionized water, and d...

Embodiment 3

[0030] 150 g of hawthorn powder was placed in an extraction container, and 1000 mL of acidic deionized water with a pH value of 6 and xylanase of 2% of the raw material quality of hawthorn powder were added. Adjust the temperature to 50 °C, the rotation speed to 200 r / min, and extract for 1 h. Cool to room temperature, set the speed of the centrifuge to 10000 r / min, centrifuge for 5 minutes, and rotate the supernatant at a temperature of 50 °C, a vacuum of -0.09 MPa, and a speed of 60 r / min to concentrate The liquid volume is 50% of the original extract volume. After cooling, the pectin extract was precipitated with 2 times the volume of the concentrate, and the pectin precipitate was collected. Then add ethanol twice the volume of the pectin precipitate to rinse and decolorize the pectin precipitate 3 times to obtain wet pectin. The wet pectin was dried with hot air at 50 ℃ for 24 h to obtain hawthorn pectin.

[0031] Add 4 g of hawthorn pectin and 8 g of gelatin into 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com