Preparation method of self-cleaning coating

A self-cleaning and coating technology, applied in the field of coatings, can solve the problems of low sunlight utilization efficiency, poor anti-fouling and decontamination effects, etc., to improve self-cleaning function, excellent automatic anti-fouling and decontamination effects, and increase utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

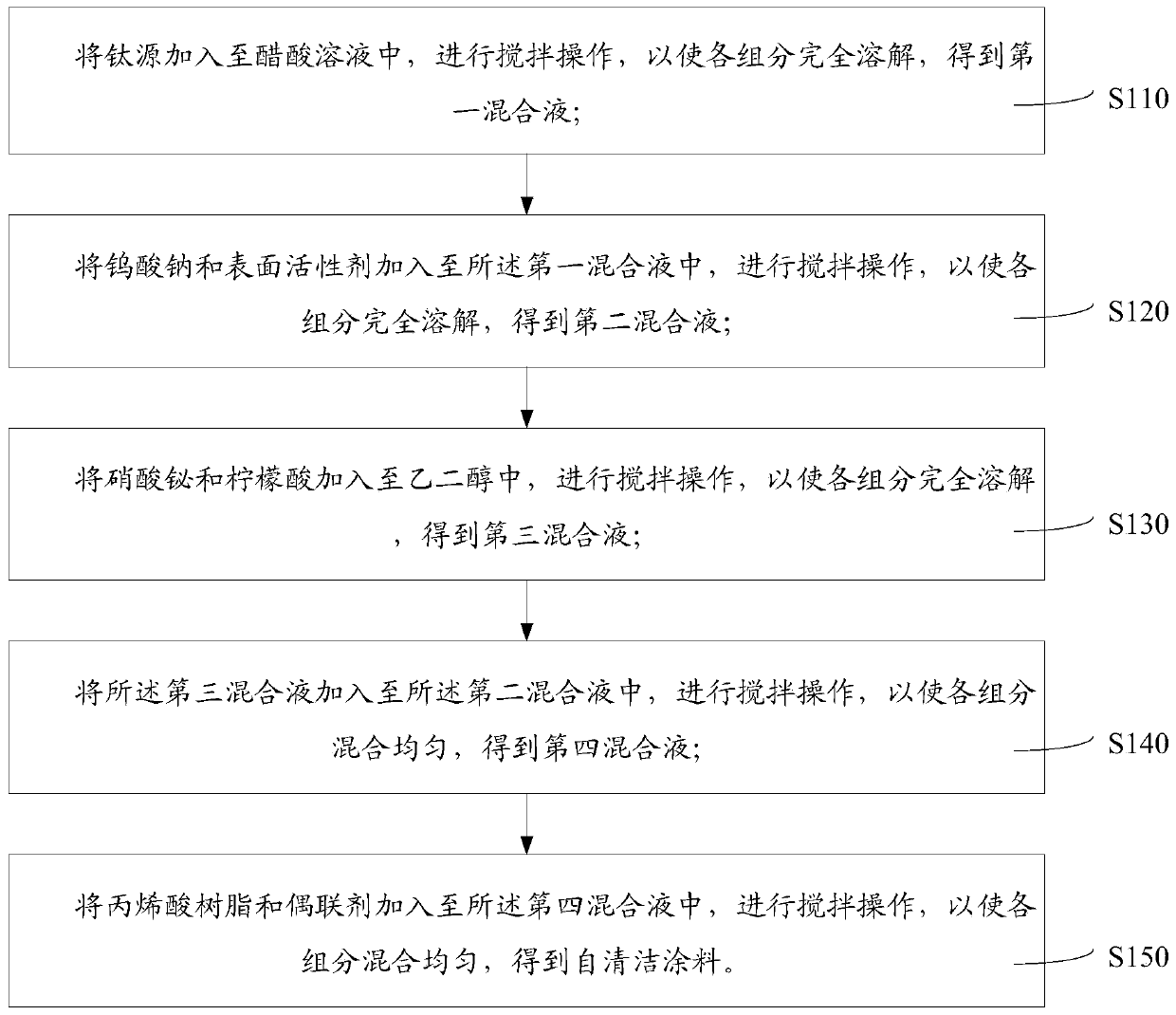

[0031]A method for preparing a self-cleaning paint, comprising the following steps: adding a titanium source into an acetic acid solution, and performing a stirring operation so that each component is completely dissolved to obtain a first mixed solution; adding sodium tungstate and a surfactant to the In the first mixed solution, a stirring operation is performed to completely dissolve each component to obtain a second mixed solution; bismuth nitrate and citric acid are added to ethylene glycol, and a stirring operation is performed to completely dissolve each component , to obtain the third mixed solution; the third mixed solution is added to the second mixed solution, and the stirring operation is carried out so that the components are mixed evenly to obtain the fourth mixed solution; the acrylic resin and the coupling agent are added Into the fourth mixed solution, stirring operation is performed to make the components uniformly mixed to obtain a self-cleaning coating.

[...

Embodiment approach

[0036] In one embodiment, the operation of adding the titanium source into the acetic acid solution and stirring to completely dissolve each component to obtain the first mixed solution is as follows: dissolving the acid in water to obtain the acetic acid solution; The titanium source is added dropwise into the acetic acid solution, the stirring operation is performed, and then left to stand until each component is completely dissolved to obtain a first mixed solution. It should be noted that adding the titanium source drop by drop can make the titanium source fully undergo hydrolysis reaction, vigorous stirring can make the titanium source uniformly dispersed and dissolved, and when the components are completely dissolved, the dissolution becomes transparent, and the hydrolysis gives Titanium dioxide can reach nano-scale sol state.

[0037] In one embodiment, the method of adding the third mixed solution to the second mixed solution is dropwise addition. It should be noted t...

Embodiment 1

[0052] S111, add 5 g of acid to 100 ml of water, and perform stirring operation to completely dissolve each component to obtain an acetic acid solution; add 3 g of n-butyl titanate dropwise to the acetic acid solution, and stop after vigorously stirring for 6 hours Stir and stand until each component is completely dissolved, at this time the solution becomes transparent to obtain the first mixed solution;

[0053] S121, adding 0.5g of sodium tungstate to the first mixed liquid, performing a stirring operation to completely dissolve each component, then adding 2g of polyvinylpyrrolidone into the first mixed liquid, and performing a stirring operation, To completely dissolve each component to obtain a second mixed solution;

[0054] S131, adding 1.47g of bismuth nitrate and 1.75g of citric acid into 100ml of ethylene glycol, and performing a stirring operation to completely dissolve each component to obtain a third mixed solution;

[0055] S141, adding the third mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com