Non-cured rubber asphalt waterproof coating, preparation method of coating and root puncture resistant waterproof material

A technology of asphalt waterproof coating and non-curing rubber, which is applied in the direction of asphalt coatings and coatings, which can solve the problems of no root puncture resistance, high dryness requirements, and limited application range, so as to eliminate fire hazards and reduce construction and maintenance costs, the effect of reducing the number of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

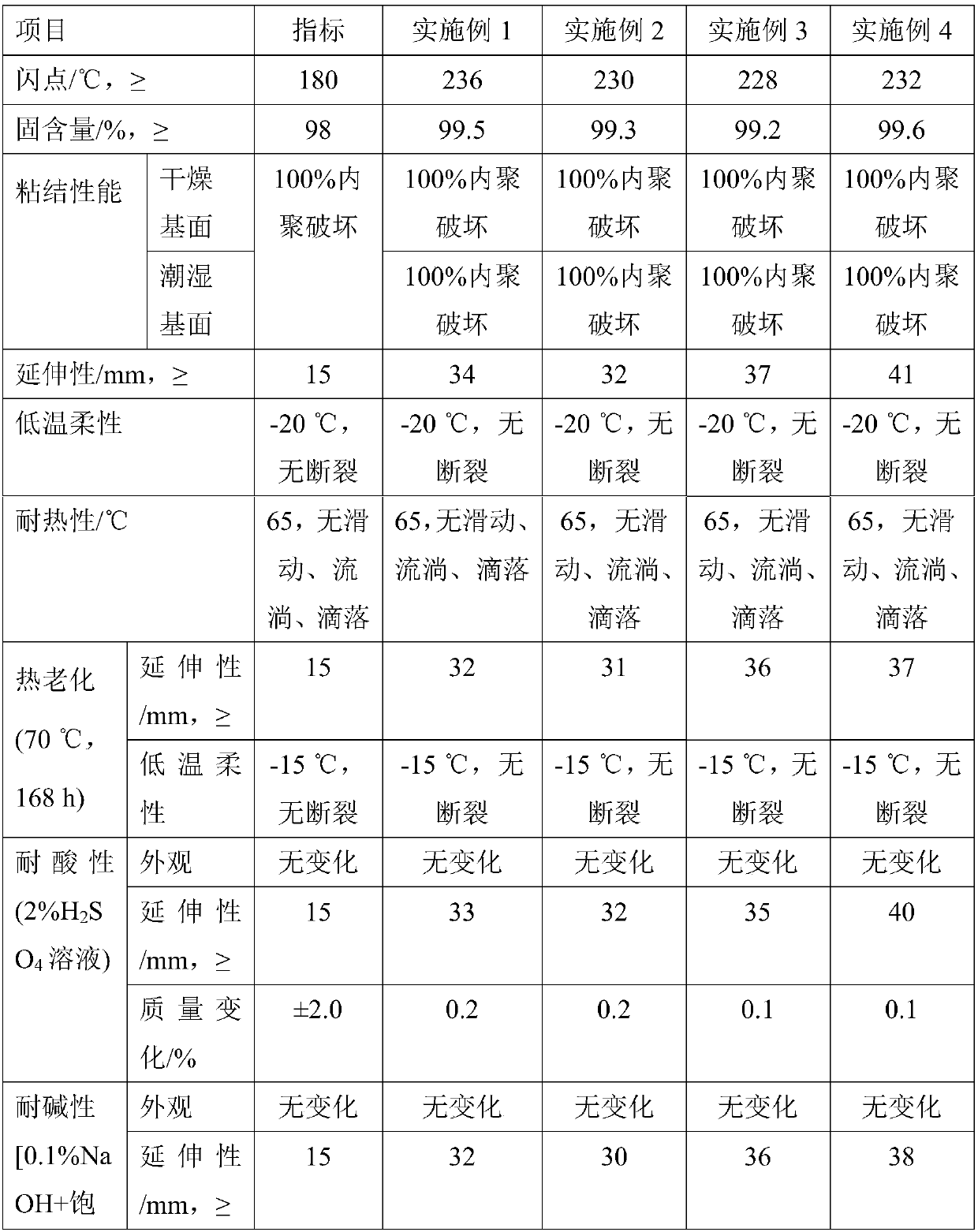

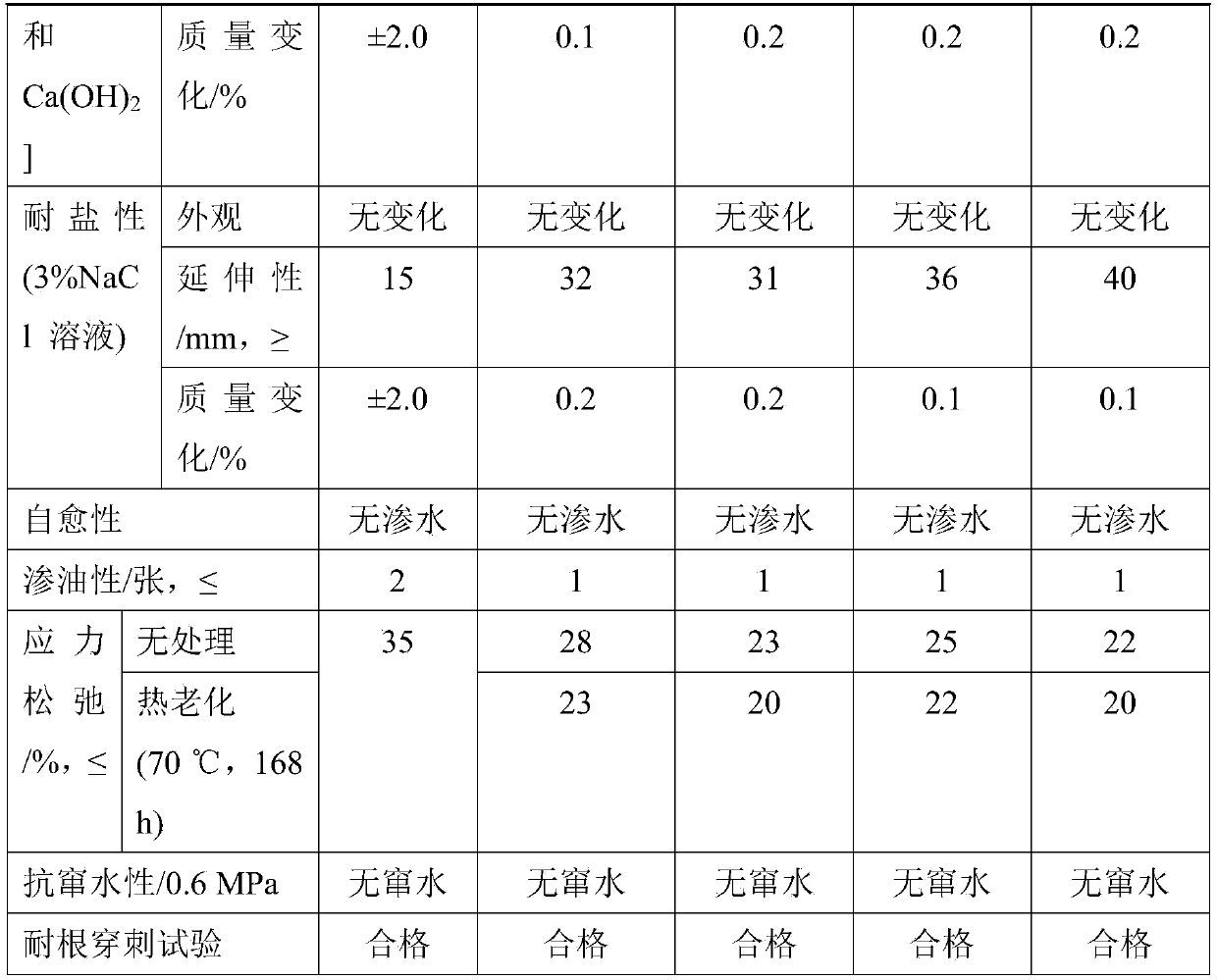

Examples

Embodiment 1

[0029] A kind of non-curing rubber asphalt waterproof coating, comprises following components by weight part: 55 parts of 70# road petroleum asphalts, 25 parts of catalytic cracking oil slurry, SBS 1301 8 parts, SBR (combined styrene content is 22% in SBR ~25%) 3 parts, coumarone resin 20 parts, 80 mesh waste rubber powder 5 parts, zeolite powder 25 parts, B2 0.5 parts.

[0030] The preparation method is:

[0031] (1) Weigh each component by parts by weight, mix petroleum pitch and softener, heat to 170°C, and stir at a speed of 2000r / min for 20min;

[0032] (2) Add modifiers SBS and SBR to the mixture of step (1), heat to 180°C, and stir at a speed of 2000r / min for 30min;

[0033] (3) Add tackifier, scrap rubber powder, filler and root inhibitor to the mixture in step (2) in sequence, cool down to 150°C, stir at 5000r / min for 60min, then cool down to room temperature.

Embodiment 2

[0035] A kind of non-curing rubber asphalt waterproof coating, comprising the following components by weight: 35 parts of 70# road petroleum asphalt, 10 parts of aromatic hydrocarbon oil, 3 parts of SBS 1401, 5 parts of SBR, 5 parts of terpene resin, 60 mesh waste 10 parts of rubber powder, 12 parts of diatomaceous earth, B2 1 copy.

[0036] The preparation method is:

[0037] (1) Weigh each component by parts by weight, mix petroleum pitch and softener, heat to 150°C, and stir at a speed of 2000r / min for 30min;

[0038] (2) Add modifiers SBS and SBR to the mixture of step (1), heat to 170°C, and stir for 40min at a speed of 2000r / min;

[0039] (3) Add tackifier, waste rubber powder, filler and root inhibitor to the mixture in step (2) in sequence, cool down to 140°C, stir at 5000r / min for 50min, then cool down to room temperature.

Embodiment 3

[0041] A kind of non-curing rubber asphalt waterproof coating, comprises the following components by weight: 45 parts of 90# road petroleum asphalt, 17 parts of naphthenic oil, 5 parts of SBS 4303, 3 parts of SBR, 12 parts of C5 petroleum resin, 100 parts 10 parts of waste rubber powder, 10 parts of bentonite, B5 0.6 parts.

[0042] The preparation method is:

[0043] (1) Weigh each component by parts by weight, mix petroleum pitch and softener, heat to 160°C, and stir for 40min at a speed of 2000r / min;

[0044] (2) Add modifiers SBS and SBR to the mixture of step (1), heat to 190°C, and stir at a speed of 2000r / min for 60min;

[0045] (3) Add tackifier, waste rubber powder, filler and root inhibitor to the mixture in step (2) in sequence, cool down to 160°C, stir at 5000r / min for 50min, then cool down to room temperature to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com