A Longitudinal Tunneling Field Effect Transistor with Improved Subthreshold Swing

A tunneling field effect, sub-threshold swing technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of sub-threshold characteristics of devices, etc., to improve on-state current, increase leakage current, and circuit design. Flexibility-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

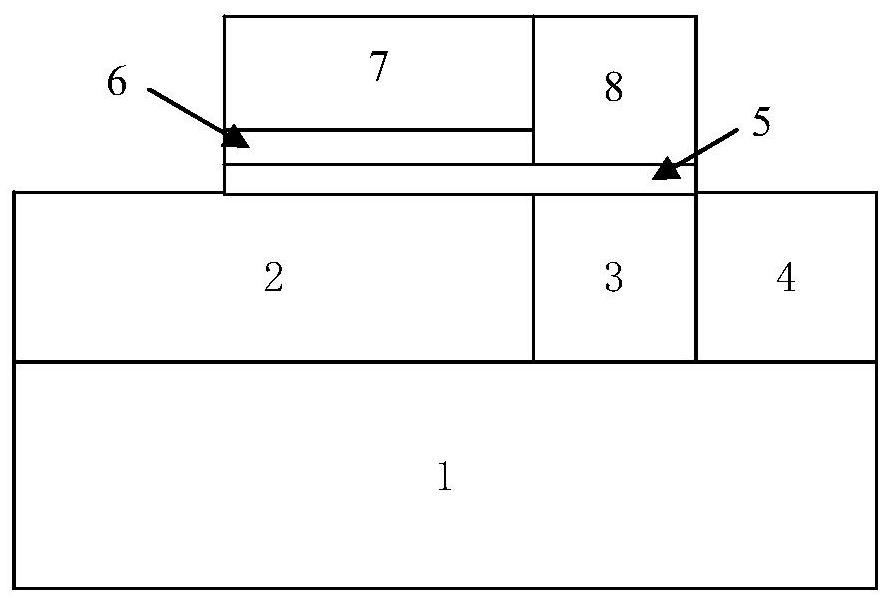

[0045] A longitudinal tunneling field effect transistor with improved sub-threshold swing according to Embodiment 1 of the present invention, its cross-sectional view can be found in figure 1 , including a semiconductor substrate 1, a source region 2, an intrinsic region 3, a drain region 4, an epitaxial region 5, a gate oxide layer 6, a metal gate 7 and a gate spacer 8, to make an N-type substrate on a P-type substrate Take TFETs as an example.

[0046] Its production process is as follows:

[0047] Step 1: Select the doping concentration as light doping (10 14 ~10 16 cm -3 ) of P-type single crystal silicon as the material of the semiconductor substrate 1, see figure 2 ;

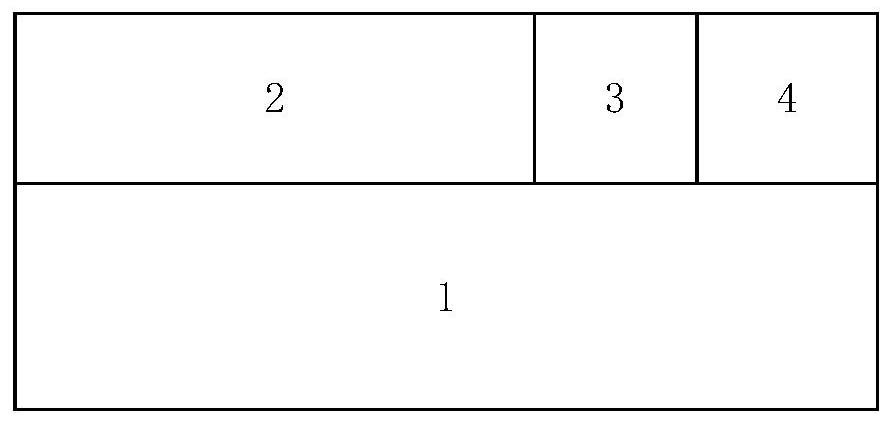

[0048] Step 2: Using an ion implantation process to form mutually independent P ++ type source region 2 and N + Type drain region 4, the region of substrate 1 between source region 2 and drain region 4 forms intrinsic region 3, see image 3 ;

[0049] Step 3: epitaxially grow a thin SiGe epitaxia...

Embodiment 2

[0058] Embodiment 2 of the present invention is a vertical heterojunction tunneling field effect transistor in which the material of the epitaxial region 5 is InAs, and its cross-sectional view can be found in figure 1 , including a semiconductor substrate 1, a source region 2, an intrinsic region 3, a drain region 4, an epitaxial region 5, a gate oxide layer 6, a metal gate 7 and a gate spacer 8, to make an N-type substrate on a P-type substrate Take TFETs as an example. The difference from the fabrication of the first embodiment is that the material of the epitaxial region 5 in the first embodiment is SiGe, and the material of the epitaxial region 5 in this embodiment is InAs.

[0059] Both InAs in Embodiment 2 and SiGe in Embodiment 1 are narrow bandgap materials. The electron affinity of the InAs material is 4.9eV, and the band gap is 0.354eV; the electron affinity of the Si material is 4.05eV, and the band gap is 1.12eV. It can be seen that the valence band positions of ...

Embodiment 3

[0061] Embodiment 3 of the present invention is a complementary vertical tunneling field effect transistor based on a gradually doped epitaxial region. Similar to CMOS, using the proposed gradient doped TFET structure, by adding a small number of masks and only changing the doping type of the corresponding region, N-TFET devices and P-TFET devices can be fabricated on the same substrate to achieve complementary longitudinal tunneling. Through the field effect transistor (TFET), its cross-section see Figure 14 , including semiconductor substrate 1, source region 2, intrinsic region 3, drain region 4, epitaxial region 5, gate oxide layer 6, metal gate 7, sidewall 8, shallow trench isolation STI9, P-epitaxial layer 10, passivation Layer 11 and metal tungsten 12, the production process is as follows:

[0062] Step 1: Select highly doped P-type single crystal silicon (Si) as the material of the semiconductor substrate 1, the resistivity of the semiconductor substrate 1 is 0.009-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com