Vertical Tunneling Field Effect Transistor with Enhanced On-state Current

A tunneling field effect and on-state current technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as poor performance of TFET devices, and achieve enhanced device on-state current, increased tunneling probability, and increased electric field. The effect of line density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

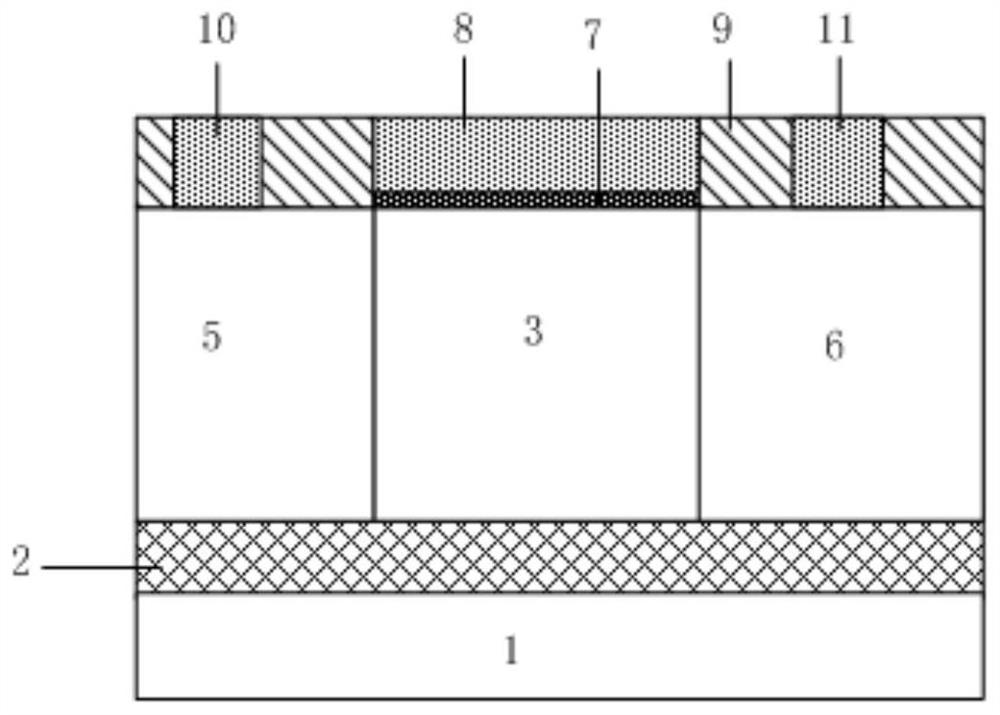

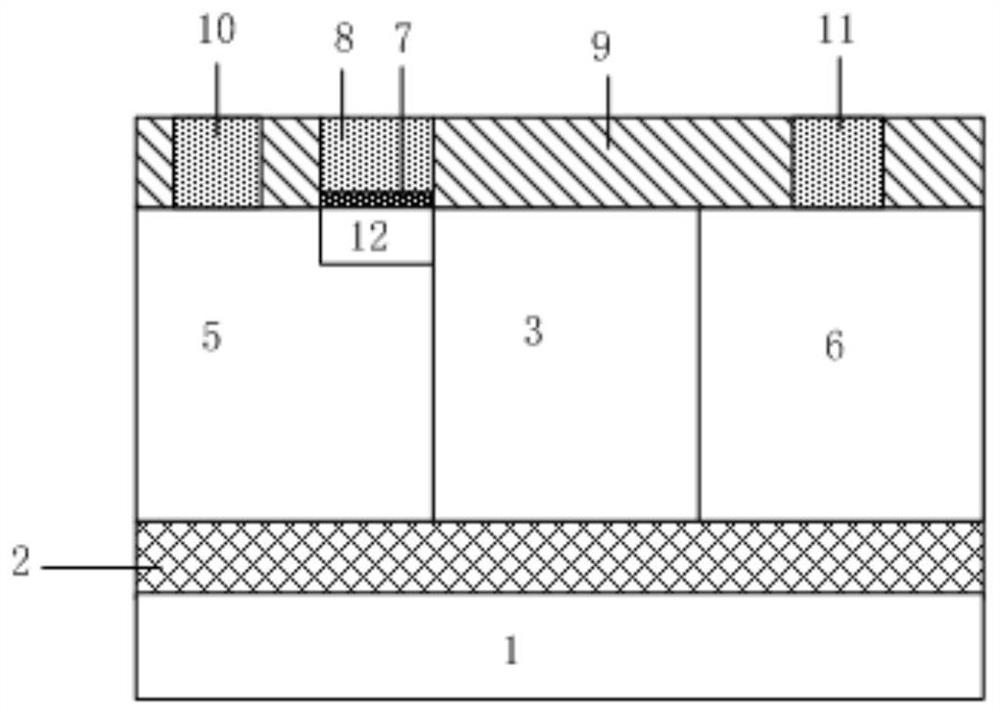

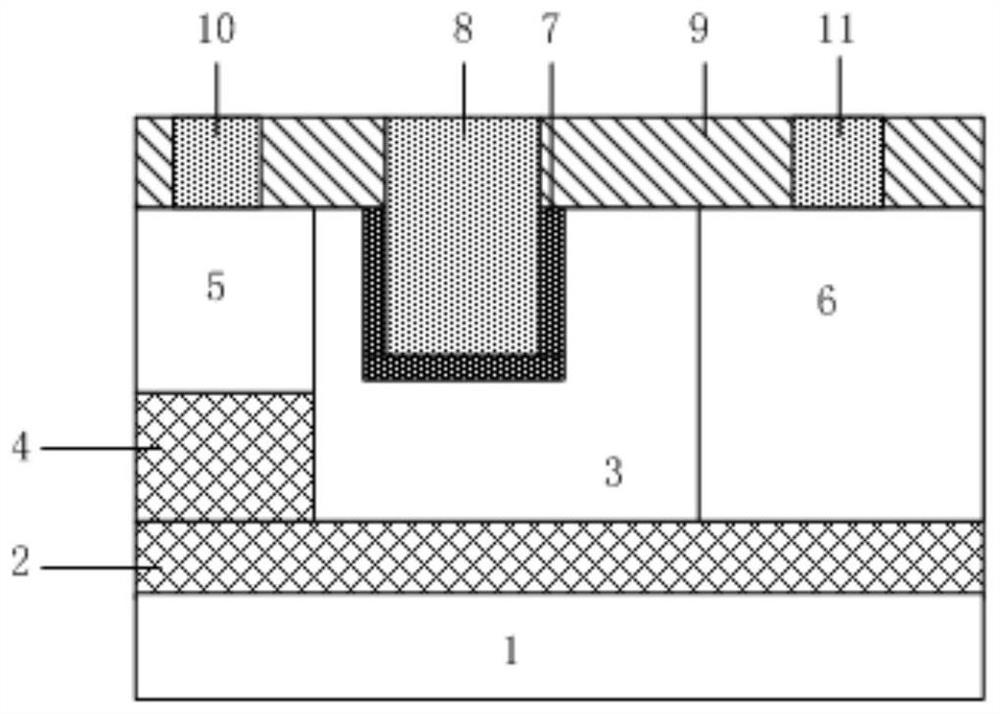

[0038] The vertical tunneling field-effect transistor with enhanced on-state current in Embodiment 1 of the present invention, its cross-sectional view can be found in image 3 , including a semiconductor substrate 1, a buried oxide layer 2, an intrinsic region 3, a source region 5, a drain region 6, a gate oxide layer 7, a gate electrode 8, sidewalls 9, a source electrode 10, a drain electrode 11 and a low-K dielectric region 4. Wherein, the buried oxide layer 2 is arranged above the semiconductor substrate 1, and its lower surface is in contact with the upper surface of the semiconductor substrate 1, and the low-K dielectric layer 4, the intrinsic region 3 and the drain region 6 are respectively arranged on the buried oxide layer 2, the lower surface of the low-K dielectric layer 4, the lower surface of the intrinsic region 3, and the lower surface of the drain region 6 are respectively in contact with the upper surface of the buried oxide layer 2, and the two sides of the in...

Embodiment 2

[0053] The vertical tunneling field-effect transistor with enhanced on-state current in Embodiment 2 of the present invention, its cross-sectional view can be found in Figure 4 , which differs from Embodiment 1 only in that the low-K dielectric region 4 adopts a vacuum with a relative permittivity of 1, which is less than the relative permittivity of silicon dioxide, 3.9, and less than the relative permittivity of silicon, 11.2. As for the vacuum medium area, it can be produced by a suitable method, and other processes are basically the same. Through simulation verification, it can be seen that under the same other conditions, the smaller the dielectric constant of the insulating material in the low-K dielectric region 4 is, the better the performance of the resulting device is. As far as the material of the low-K dielectric region 4 is concerned, the electric field enhancement effect is the best when a vacuum is used.

Embodiment 3

[0055] The on-state current-enhanced vertical tunneling field effect transistor in Embodiment 3 of the present invention, its cross-sectional view can be found in Figure 5, the difference from Embodiment 1 is only that: the SOI silicon wafer for making the device is replaced by a common non-SOI silicon wafer, so that the materials of the semiconductor substrate 1 and the buried oxide layer 2 are the same as those of the intrinsic region 3, and other processes are basically the same . Since the price of ordinary silicon wafers is much lower than that of SOI silicon wafers, device manufacturing costs can be reduced. At the same time, the advantages of strong gate control ability, large tunneling area, and low-K dielectric region 4 are helpful to increase the tunneling electric field under the tunneling junction and reduce device leakage. However, the advantages of increased tunneling junction electric field and reduced leakage obtained by devices on ordinary silicon wafers wil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com