A kind of extraction and purification method of cannabidiol

A technology of cannabidiol and purification methods, which is applied in chemical instruments and methods, organic chemistry, bulk chemical production, etc., can solve the problems of inability to fully remove heavy metal residues, cannabidiol safety adverse reactions, and end product safety. Avoid hidden dangers and other problems, and achieve the effect of narrow dissolution spectrum, easy access, and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

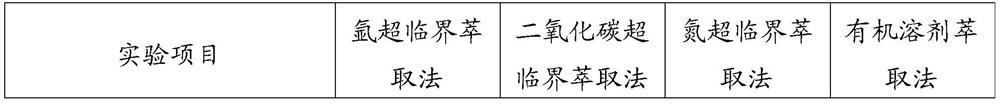

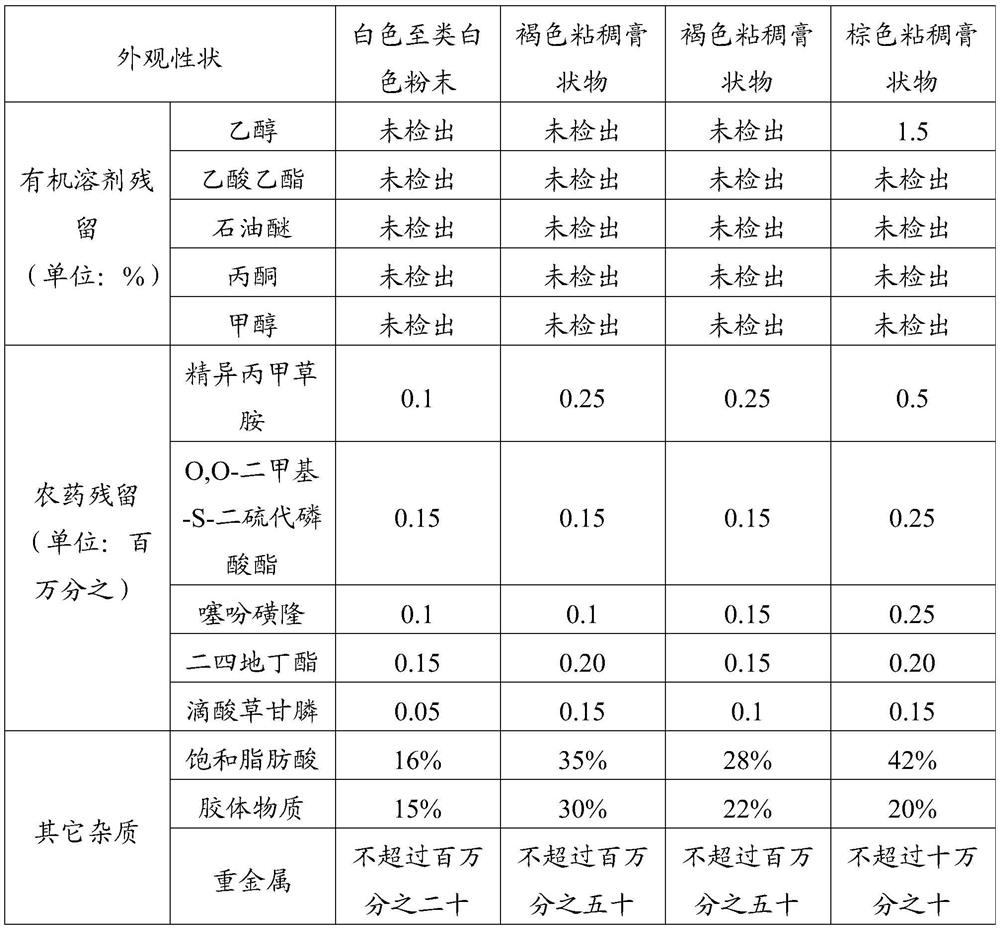

Examples

Embodiment 1

[0030] (1) Dry the cannabis flowers, leaves or seed coats with a hot air circulating bellows at 120°C to a moisture content of not more than 6%;

[0031] (2) pulverize the dried cannabis flower, leaf or seed coat to a particle size of 100 mesh;

[0032] (3) Use supercritical argon extraction method to extract the crushed cannabis flowers, leaves or seed coats, the extraction temperature is 20 ° C, and the stage pressure control method is used to make the argon pressure reach the supercritical state of 30 MPa, and the extraction time is 5 hours, the desorption temperature is 20 °C, and the desorption pressure is 10 MPa to obtain cannabis extract;

[0033] (4) adopt molecular distillation method, the cannabis extract obtained in step (3) is distilled 5 times, and distillation temperature is 180 ℃, and vacuum tightness is 10Pa, obtains crude cannabis oil;

[0034] (5) the crude hemp oil obtained in step (4) is dissolved with 12 times of weight of ethanol or methanol, and argon s...

Embodiment 2

[0037] (1) Dry the cannabis flowers, leaves or seed coats with a hot air circulating air box at 60°C to a moisture content of not more than 6%;

[0038] (2) pulverize the dried cannabis flower, leaf or seed coat to a particle size of 20 mesh;

[0039] (3) Use supercritical argon extraction method to extract the crushed cannabis flowers, leaves or seed coats, the extraction temperature is -70 ° C, and the stage pressure control method is used to make the argon gas pressure reach the supercritical state of 5MPa, and the extraction time is 0.5 hours, the desorption temperature is -70°C, and the desorption pressure is 1MPa to obtain hemp extract;

[0040] (4) adopt molecular distillation method, the cannabis extract obtained in step (3) is distilled 2 times, the distillation temperature is 115 ℃, and the vacuum tightness is 0.5Pa, obtains crude cannabis oil;

[0041] (5) the crude hemp oil obtained in step (4) is dissolved with 6 times of weight of ethanol or methanol, and argon ...

Embodiment 3

[0044] (1) Dry the cannabis flower, leaf or seed coat with a hot air circulating air box at 150°C to a moisture content of not more than 6%;

[0045] (2) pulverize the dried cannabis flower, leaf or seed coat to a particle size of 100 mesh;

[0046](3) Use supercritical argon extraction method to extract the crushed cannabis flowers, leaves or seed coats, the extraction temperature is 40 ° C, and the stage pressure control method is used to make the argon pressure reach the supercritical state of 50 MPa, and the extraction time is 5 hours, the desorption temperature is 20°C, and the desorption pressure is 20MPa to obtain hemp extract;

[0047] (4) adopt molecular distillation method, the cannabis extract obtained in step (3) is distilled 5 times, the distillation temperature is 220 ℃, and the vacuum tightness is 20Pa, obtains crude cannabis oil;

[0048] (5) the crude hemp oil obtained in step (4) is dissolved with 20 times of weight of ethanol or methanol, and argon supercri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com