Anti-cracking and anti-floating fiber-reinforced synchronous grouting slurry for shield construction

A fiber reinforcement and synchronous grouting technology, applied in the field of tunnel shield construction, can solve the problems of limited shear and tensile capacity, staggered opening of segment joints, leakage of water in shield tunnels, etc. The effect of small shrinkage, fast strength growth and low bleeding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: A fiber-reinforced synchronous grouting slurry for anti-cracking and anti-floating shield construction, consisting of cement, medium coarse sand, montmorillonite mineral powder, water, sodium nitrite, water reducing agent and monofilament bundle fibers mixed. Its mixing ratio (mass ratio) is:

[0020] Water: cement = 1:1; cement: medium coarse sand = 0.4:1; montmorillonite mineral powder: cement = 1:1; sodium nitrite: cement = 4%; water reducer: cement mass = 0.5%, fiber : cement=0.5%.

[0021] The cement is 42.5 grade ordinary Portland cement; the water reducer is naphthalene water reducer; the fiber is alkali-resistant glass fiber, and the fiber length is 12mm.

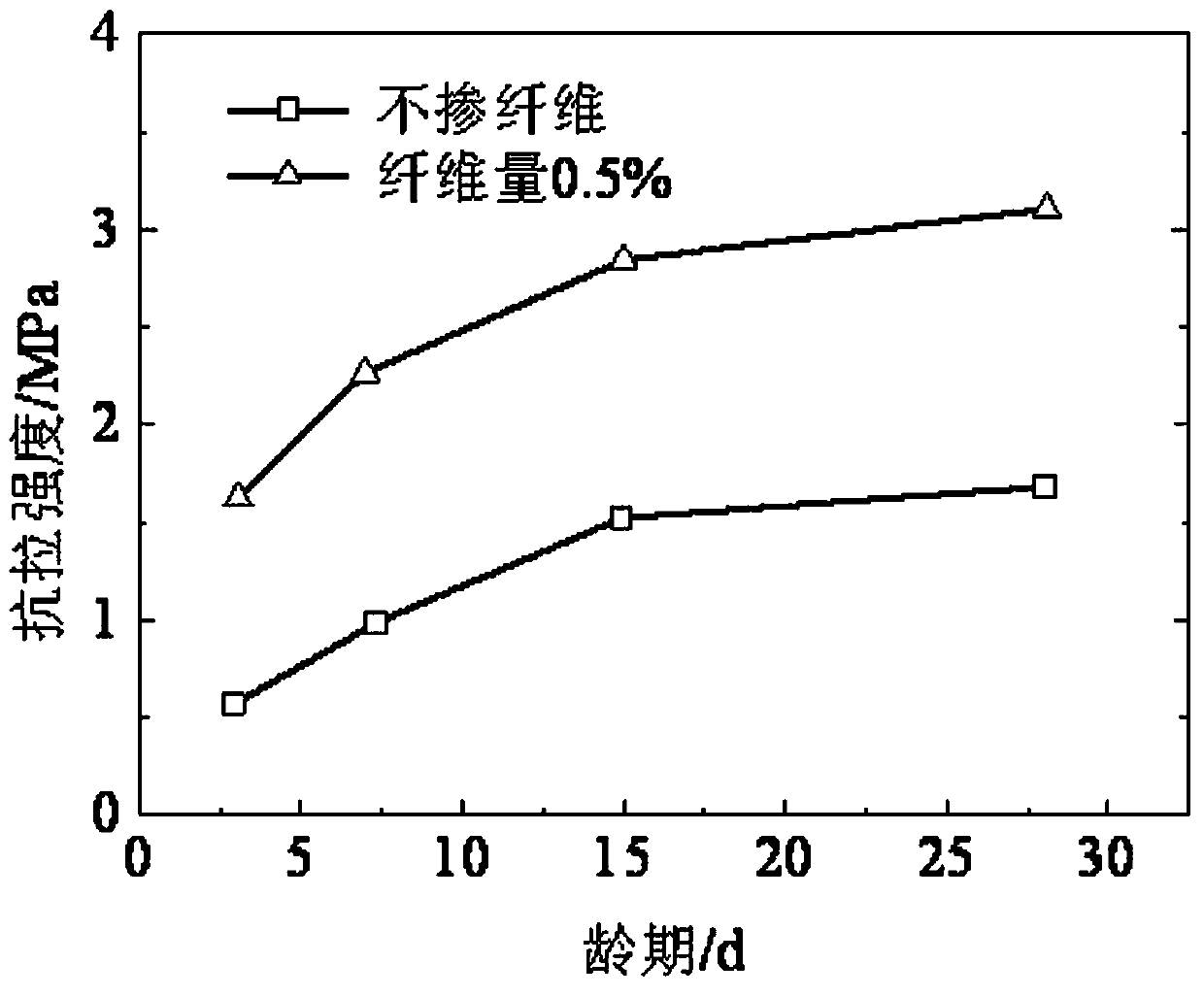

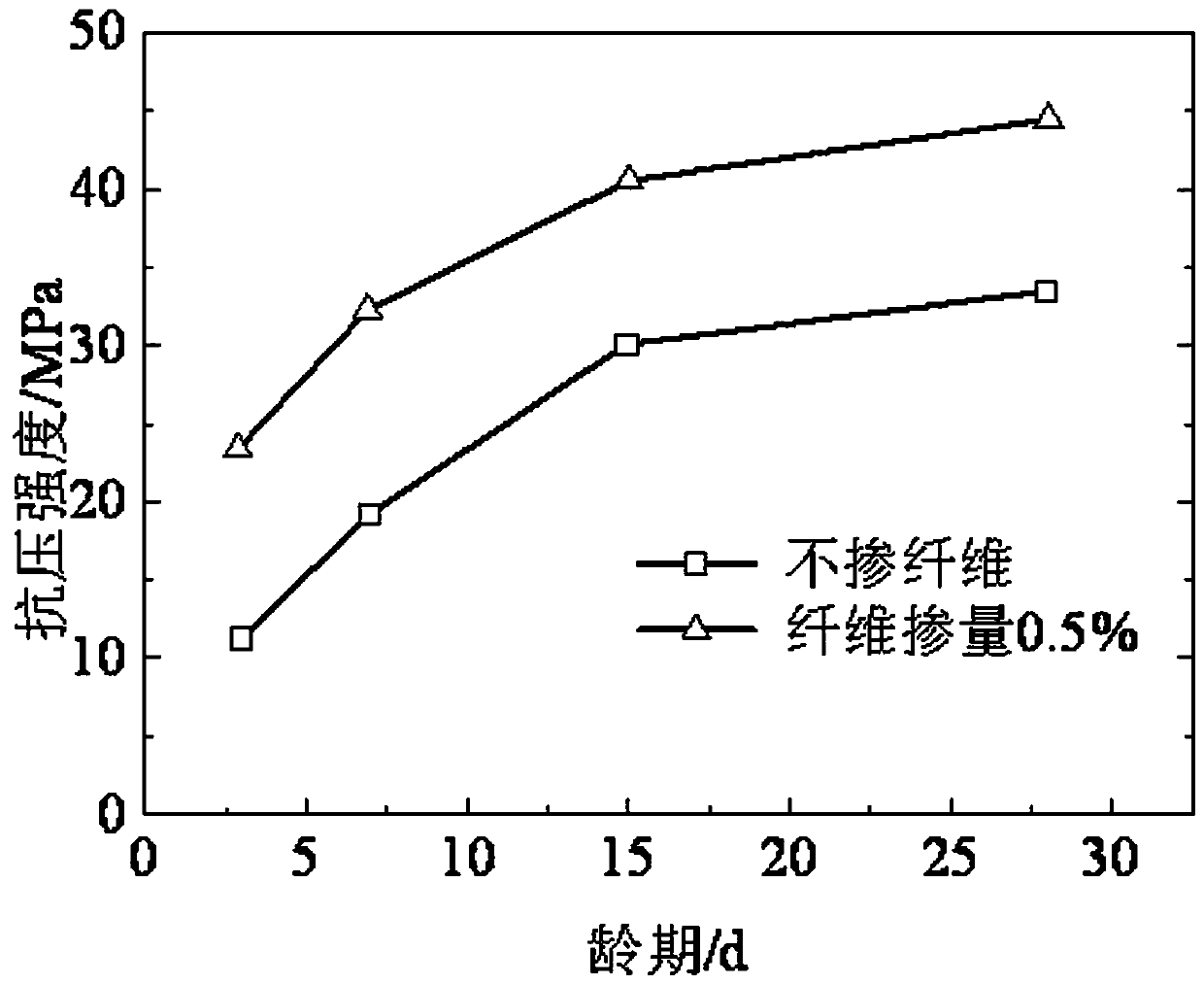

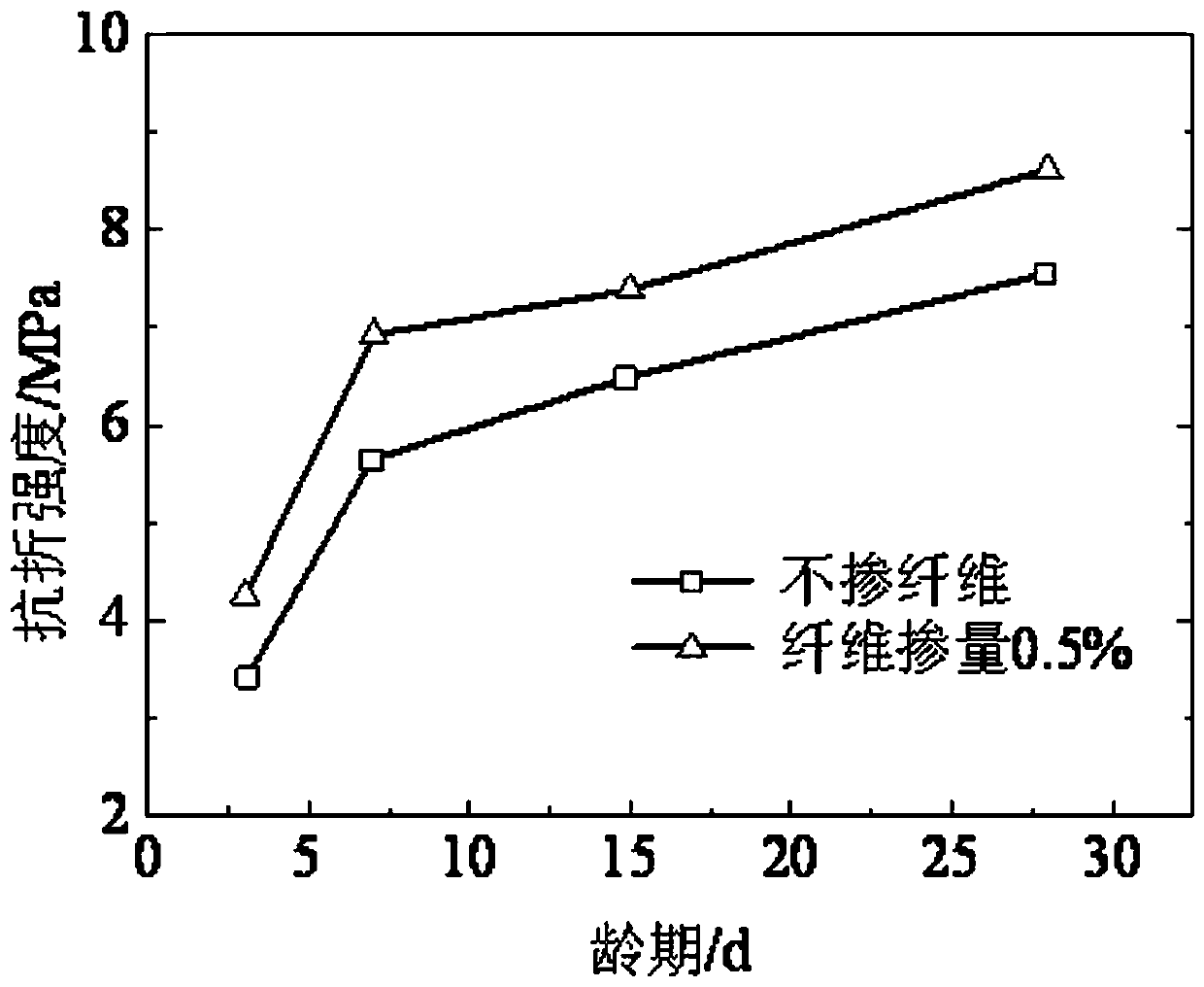

[0022] The performance of the solidified body of the fiber reinforced synchronous grouting grout for shield construction prepared according to the above ratio is as follows: Figure 1~4 As shown, the 28-day quality index is shown in Table 1.

[0023] Table 1

[0024]

[0025] It can be clea...

Embodiment 2

[0026] Example 2: A fiber-reinforced synchronous grouting slurry for anti-cracking and anti-floating shield construction, consisting of cement, medium coarse sand, montmorillonite mineral powder, water, sodium nitrite, water reducing agent and monofilament bundle fibers mixed. Its mixing ratio (mass ratio) is:

[0027] Water: cement = 1.1:1; cement: medium coarse sand = 0.6:1; montmorillonite mineral powder: cement = 1:1; sodium nitrite: cement = 6%; water reducer: cement mass = 2%, fiber : cement=0.3%.

[0028] The cement is 42.5 grade ordinary Portland cement; the water reducer is lignosulfonate water reducer; the fiber is polypropylene fiber with a fiber length of 8mm.

Embodiment 3

[0029] Embodiment 3: A kind of anti-cracking, anti-floating shield construction fiber reinforced synchronous grouting slurry, which is composed of cement, medium coarse sand, montmorillonite mineral powder, water, sodium nitrite, water reducing agent and monofilament bundle fiber mixed. Its mixing ratio (mass ratio) is:

[0030] Water: cement = 1.2:1; cement: medium coarse sand = 0.3:1; montmorillonite mineral powder: cement = 1:1; sodium nitrite: cement = 3%; water reducer: cement mass = 0.2%, fiber : cement=0.1%.

[0031] The cement is 42.5 grade ordinary Portland cement; the water reducer is fatty acid water reducer; the fiber is polyethylene fiber, and the fiber length is 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com