Ionic liquid-based ECF bleaching protection agent for paper pulp

An ionic liquid, pulp bleaching technology, applied in pulp bleaching, cellulose pulp post-treatment, washing/replacement pulp treatment liquid, etc. Stable, easy to promote, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

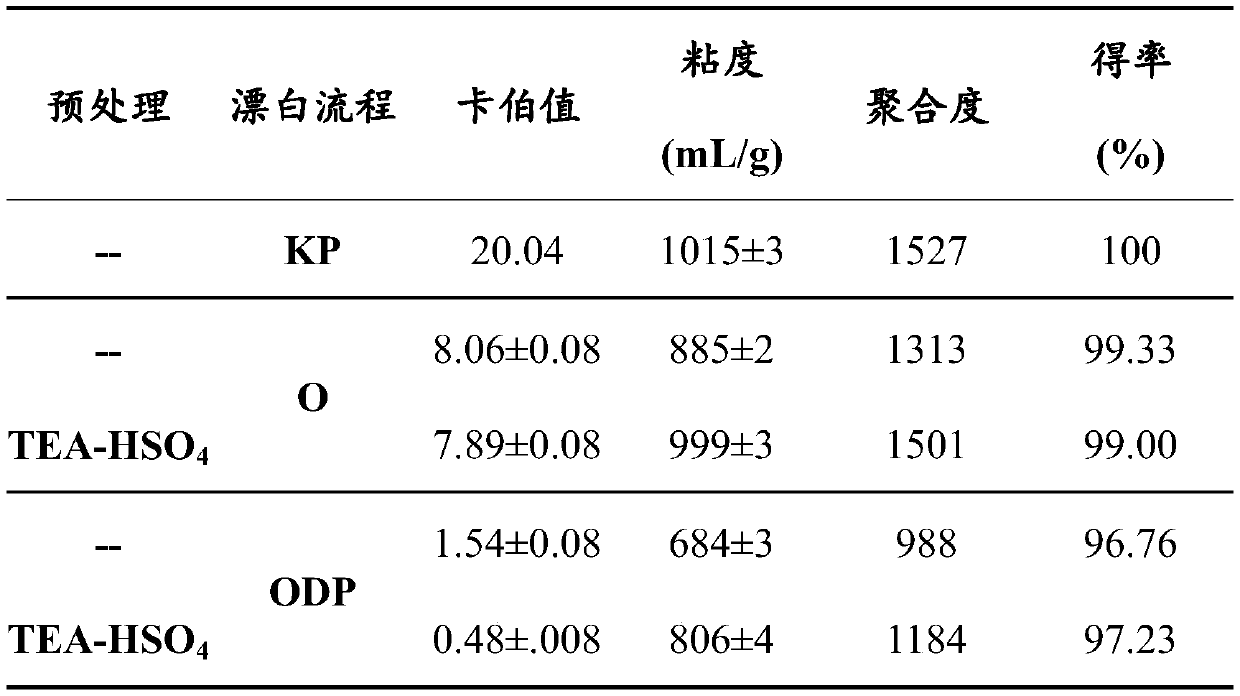

[0068] Proceed as follows:

[0069] (1) Cooking: the amount of alkali used in eucalyptus chips is 21%, Na 2 O meter; degree of sulfide 25%, liquid ratio 1:5, cooking at a maximum temperature of 170°C. Degassing is carried out at 105°C, the heating time is 90 minutes, and the holding time is 90 minutes. After cooking, fully wash and screen to obtain pulp.

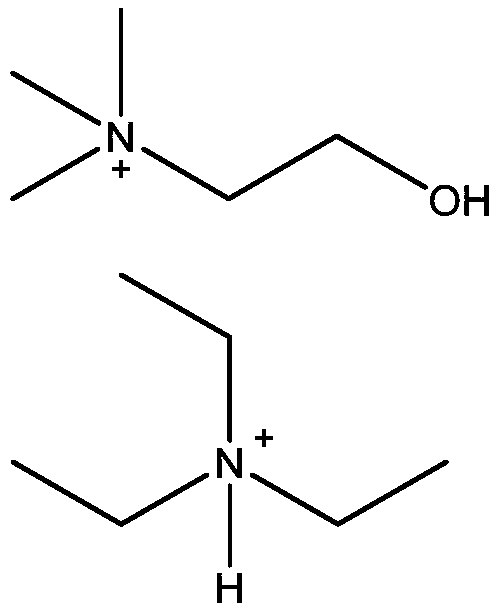

[0070] (2) Protective agent pretreatment: Accurately weigh three bags of 25g above-mentioned eucalyptus sulfate slurry (dry pulp meter), measure 10% triethylammonium bisulfate ionic liquid (TEA-HSO 4 )-based bleach protectant (the bleach protectant except TEA-HSO 4 In addition, a small amount of anhydrous magnesium sulfate (0.6%) is added into the slurry, and the slurry concentration is adjusted to 10% in a polyethylene bag, and kneaded to mix evenly.

[0071] (3) ECF bleaching: the above-mentioned pretreated pulp is bleached, and the bleaching process is an ODP bleaching process. The steps are: first, O-stage oxygen del...

Embodiment 2

[0082] Proceed as follows:

[0083] (1) Cooking: The condition is that the amount of alkali used is 21%, Na 2O meter; degree of sulfidation 25%, liquid ratio 1:5, maximum cooking temperature 170°C, degassing at 105°C, heating time 90min, holding time 90min; fully wash and screen after cooking to obtain pulp.

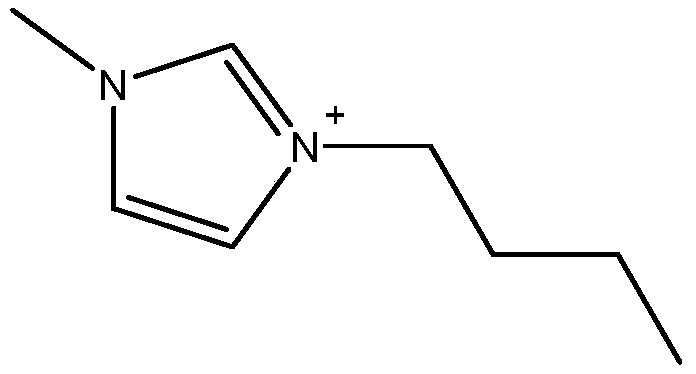

[0084] (2) ultrasonic synergistic ionic liquid treatment: accurately weigh three bags of 25g slurry (dry pulp meter), measure 5%, 10%, 15% 1-butyl 3-methyl hydrogensulfate ionic liquid ( BMIM-HSO 4 ) into the slurry, adjust the slurry concentration to 10% in a polyethylene bag, and knead until mixed evenly

[0085] (3) ECF bleaching: the above-mentioned pretreated pulp is bleached, and the bleaching process is an ODP bleaching process. The steps are: first, O-stage oxygen delignification is carried out to eucalyptus kraft pulp. The process is: pulp concentration 10%, NaOH Dosage 3%, oxygen pressure 0.5MPa, temperature 100°C, time 60min, MgSO 4 The dosage is 0.6%; fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com