3D printing antibacterial hydrogel wound dressing based on green in-situ reduction

A 3D printing and wound dressing technology, applied in 3D object support structures, additive manufacturing, medical science, etc., can solve the problems of weak antibacterial performance of antibacterial hydrogel, potential safety hazards in the preparation method, and inability to meet antibacterial requirements, etc., to achieve reduction Effects of potential cytotoxicity, excellent antibacterial properties, and high water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

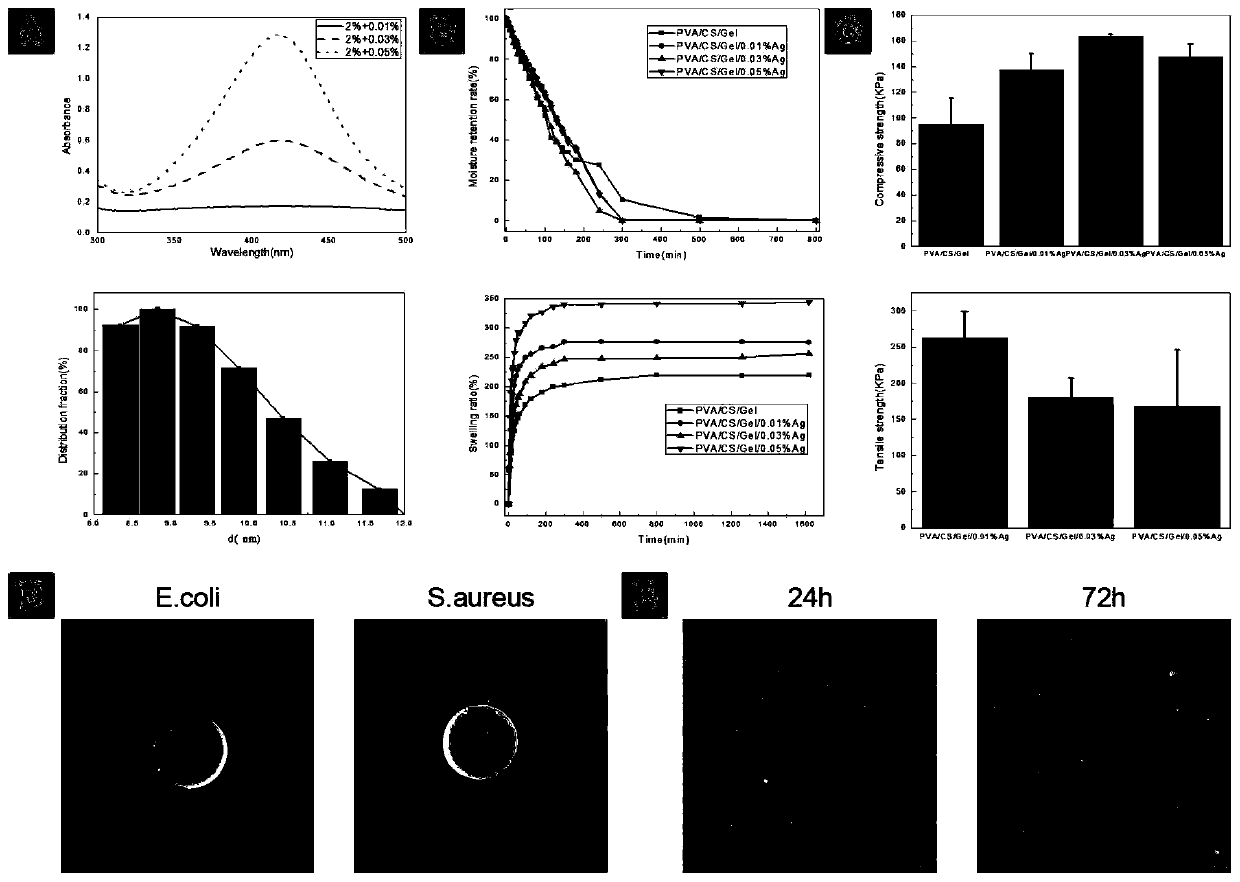

[0028] The invention discloses a preparation method of a 3D printed antibacterial hydrogel wound dressing based on green in situ reduction. The preparation materials include: raw materials for reducing nano-silver: gelatin, silver nitrate; raw materials for constructing hydrogel: polyvinyl alcohol, chitosan, gelatin, deionized water; raw materials for cross-linking hydrogel: sodium citrate.

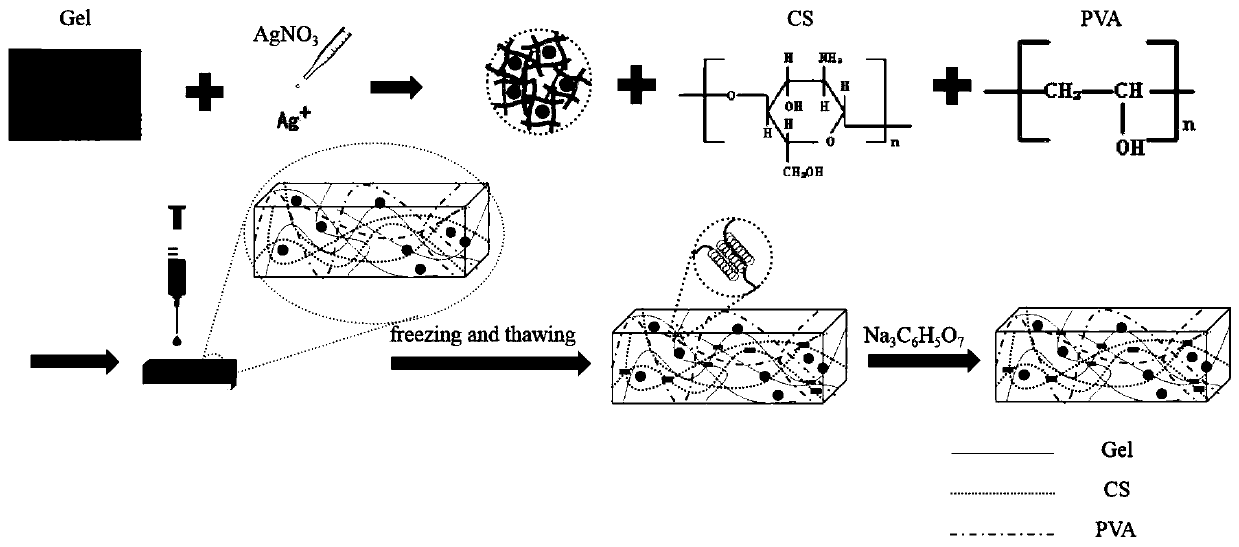

[0029] Such as figure 1 As shown, the preparation process:

[0030] (1) prepare nanometer silver-gelatin solution;

[0031] (2) prepare polyvinyl alcohol / chitosan / gelatin solution;

[0032] (3) Prepare the solution to be printed;

[0033] (4) 3D printing hydrogel on non-woven fabric;

[0034] (5) Cross-linking (freezing-thawing and soaking in sodium citrate) the sample prepared in step 4; thereby obtaining a silver-loaded polyvinyl alcohol / chitosan / gelatin hydrogel wound dressing.

[0035] The prepared hydrogel wound dressing figure 2 Shown, in line with the requirements of the ide...

Embodiment 1

[0038] 1) Reduction of nano-silver: dissolving gelatin in deionized water, heating in a water bath at 50° C. and fully stirring to obtain a gelatin solution with a mass fraction of 2%; preparing a silver nitrate solution with a mass fraction of 1%. The silver nitrate solution was added dropwise to the sodium alginate solution at a mass ratio of 3:100, reacted at 90°C in the dark for more than 10 hours, and stirred vigorously to obtain a yellow nano-silver-gelatin solution.

[0039] 2) Preparation of polyvinyl alcohol / chitosan / gelatin solution: Dissolve polyvinyl alcohol in deionized water, fully swell, heat and stir in a water bath at 95° C., and fully dissolve. Add acetic acid, chitosan, and sodium alginate, and stir evenly at 50° C. to obtain a polyvinyl alcohol / chitosan / gelatin solution.

[0040] 3) Preparation of the solution to be printed: Mix the nano-silver-gelatin solution and the polyvinyl alcohol / chitosan / gelatin solution at a volume ratio of 1:1, stir evenly, and re...

Embodiment 2

[0044] 1) Reduction of nano-silver: dissolving gelatin in deionized water, heating in a water bath at 50° C. and fully stirring to obtain a gelatin solution with a mass fraction of 2%; preparing a silver nitrate solution with a mass fraction of 1%. The silver nitrate solution was added dropwise to the sodium alginate solution at a mass ratio of 3:100, reacted at 90°C in the dark for more than 10 hours, and stirred vigorously to obtain a yellow nano-silver-gelatin solution.

[0045] 2) Preparation of polyvinyl alcohol / chitosan / gelatin solution: Dissolve polyvinyl alcohol in deionized water, fully swell, heat and stir in a water bath at 95° C., and fully dissolve. Add acetic acid, chitosan, and sodium alginate, and stir evenly at 50° C. to obtain a polyvinyl alcohol / chitosan / gelatin solution.

[0046] 3) Preparation of the solution to be printed: Mix the nano-silver-gelatin solution and the polyvinyl alcohol / chitosan / gelatin solution at a volume ratio of 1:1, stir evenly, and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com