A wire-drawing process for automobile signs

A technology for car signage and wire drawing, applied in manufacturing tools, metal processing equipment, detergent compounding agents, etc., can solve the problems of affecting mechanical efficiency, production process and product performance, no effect, particularly good non-foaming cleaning agent, difficult to remove, etc. , to achieve the effect of high dispersibility, high dispersion retention and easy diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

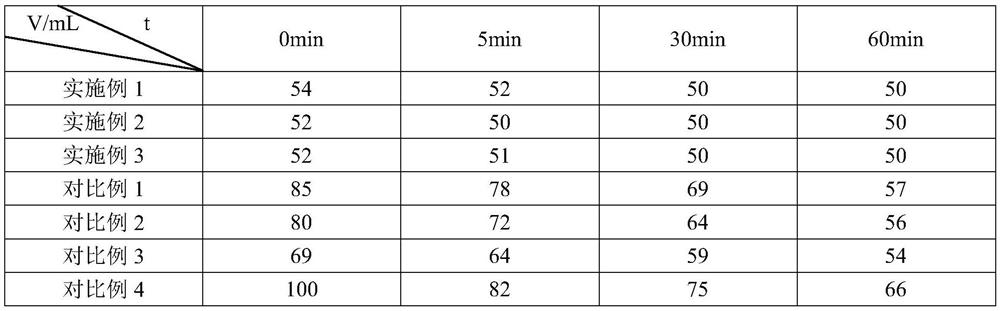

Examples

Embodiment 1

[0046] A brushed process of a car sign, including the following steps:

[0047] S1, brushed step;

[0048] a. With a laser laser machine for a draw; surface as a brushed brushed protruding, the vacuum is 2.5 - 1PA, frequency 30kHz, speed is 1500mm / s, temperature 50 ° C, time 30 min;

[0049] b. Secondary brushed wire by laser laser machine; surface as a brushed wire, vacuum is 2.5 -1 PA, frequency 30kHz, speed is 1500mm / s, temperature 50 ° C, time 30 min;

[0050] c. Ultrasonic treatment; time 3min;

[0051] d. Surface wiping;

[0052] S2, PVD surface treatment process;

[0053] Step 1, PVD before processing; cleaning the car sign by cleaning agent, time 15 min;

[0054] Step 2, bake; for 10 min at a vacuum oven temperature at 80 ° C;

[0055] Step 3, hang;

[0056] Step 4, the plating film;

[0057] Step 5, hang up.

[0058] The preparation step of the cleaning agent in step 1 is: weigh the desired component, first add methyl trionoxysilane, sodium methylpropylene sulfonate ...

Embodiment 2

[0061] A brushed process of a car sign, including the following steps:

[0062] S1, brushed step;

[0063] a. With a laser laser machine for a draw; surface as a brushed brushed protruding, the vacuum is 2.5 - 1 PA, frequency 40kHz, speed of 1600mm / s, temperature 60 ° C, time 35min;

[0064] b. Secondary brushed wire by laser laser machine; surface as a brushed wire, vacuum is 2.5 -1 PA, frequency 40kHz, speed of 1600mm / s, temperature 60 ° C, time 35min;

[0065] c. Ultrasonic treatment; time 5 min;

[0066] d. Surface wiping;

[0067] S2, PVD surface treatment process;

[0068] Step 1, PVD before processing; cleaning the car sign by cleaning agent, time 25min;

[0069] Step 2, bake; for 15 min at a vacuum furnace temperature of 80 ° C;

[0070] Step 3, hang;

[0071] Step 4, the plating film;

[0072] Step 5, hang up.

[0073] The preparation step of the cleaning agent in step 1 is: weigh the desired component, first add methyl trionoxysilane, sodium methylpropylene sulfonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com