Method for treating sewage of artificial board fiber dry tail gas treatment

A technology for drying tail gas and treatment method, which is applied in gas treatment, gaseous discharge wastewater treatment, filtration treatment and other directions to achieve the effect of improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

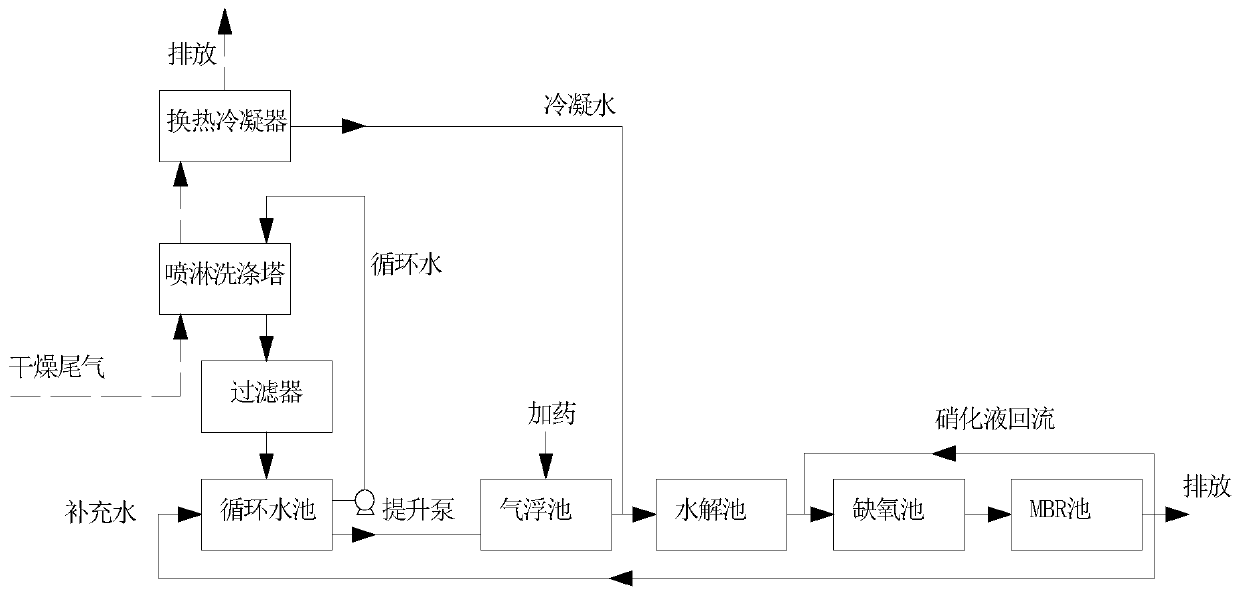

[0021] a) The dry tail gas of wood-based panel fibers enters the lower part of the spray scrubber to remove a large amount of dust and pollutants. At the same time, the circulating water enters from the upper part of the spray scrubber by the lift pump and contacts with the dry tail gas of wood-based panel fibers in reverse, so that the circulating water washes the man-made Board fiber drying tail gas, after washing, the circulating water contains a large amount of suspended solids, organic matter, formaldehyde and salt, etc.;

[0022] b) After being sprayed by the spray washing tower, the dry tail gas of wood-based panel fibers contains saturated water, and then enters the heat exchange condenser to achieve the condensation effect through heat exchange, and the condensation temperature drops from 54-55°C to 48-50°C. After the heat exchange condenser is condensed, 500-600t / d of condensed water is discharged into the hydrolysis tank, and part of the heat is recovered to reduce t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com