Silicon dioxide thermal insulation composite material and preparation method and application thereof

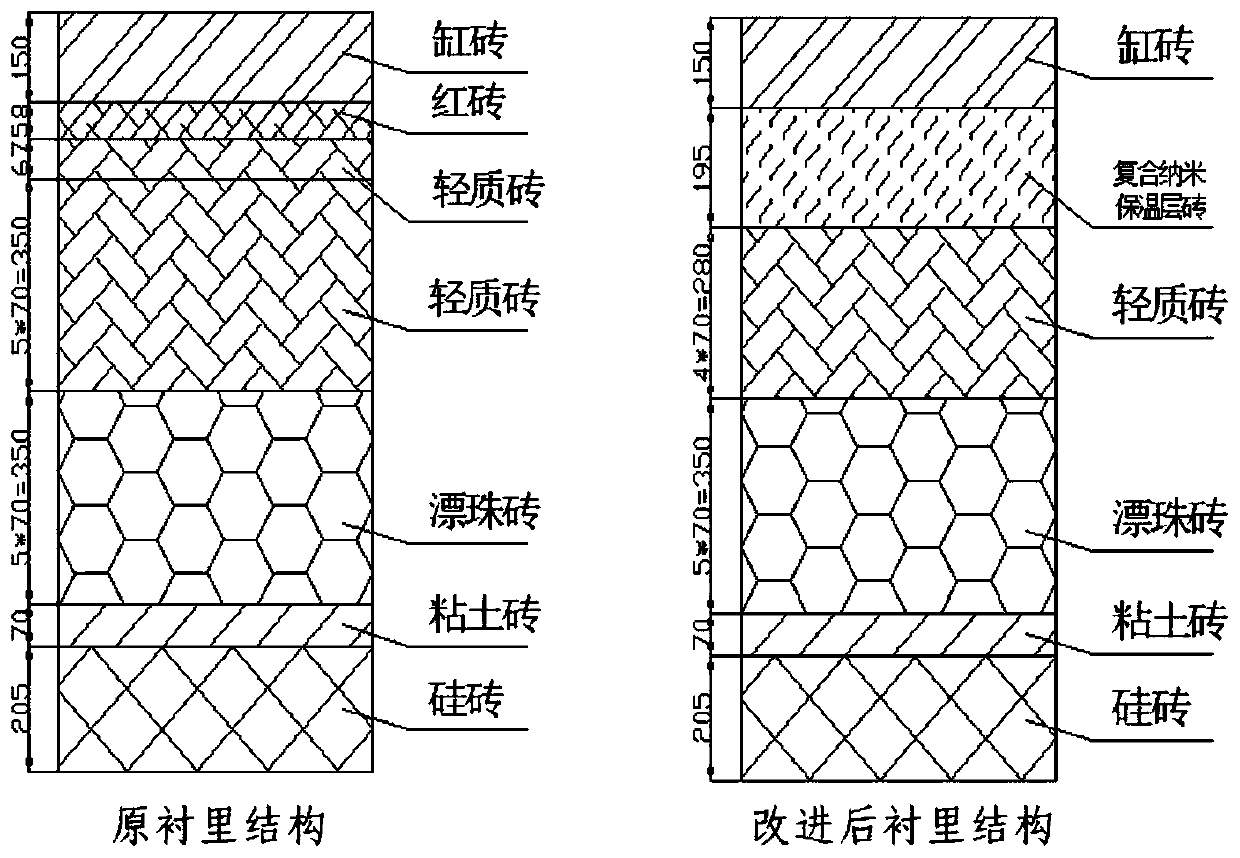

A composite material, silicon dioxide technology, applied in the field of silicon dioxide thermal insulation composite materials, can solve the problem of large heat loss in coke ovens, achieve the effects of reducing the temperature of the outer wall of the furnace, reducing the weight of equipment, and improving the operating environment of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

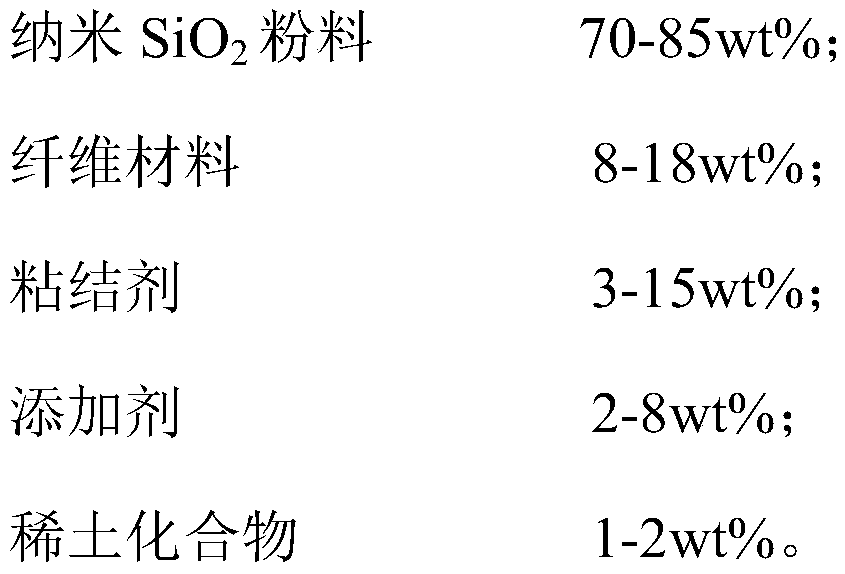

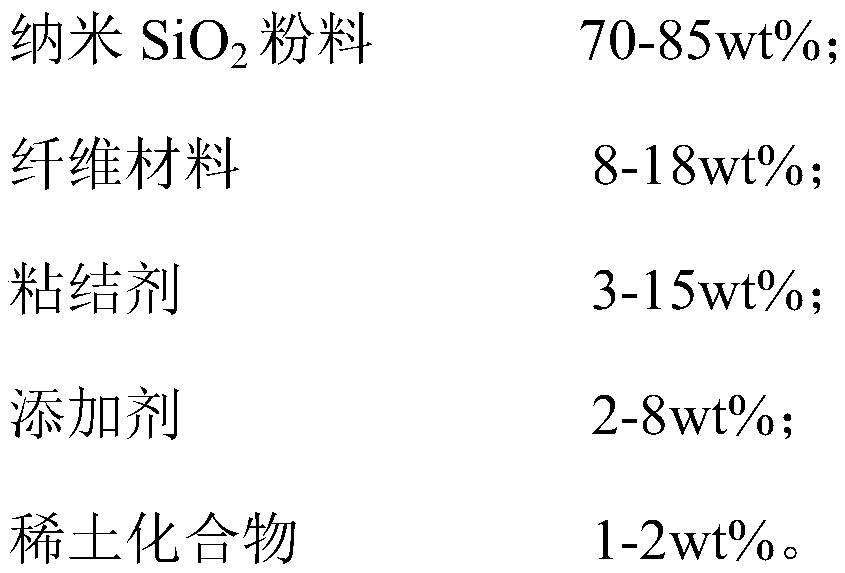

[0030] The silica thermal insulation composite material described in this embodiment includes the following raw material components:

[0031]

[0032]

[0033] The preparation method of the silica thermal insulation composite material described in this embodiment comprises the following steps:

[0034] (1) get the nano-SiO according to the selected ratio 2 Powder, fiber material, binder, additive and rare earth compound are mixed and mixed at high speed;

[0035] (2) Compress the obtained mixture at normal temperature and under a pressure of 1.581MPa-5.5MPa, and then fix and mold it with aluminum foil paper after pressing, and then dry it to obtain the desired thermal insulation composite material.

Embodiment 2

[0037] The silica thermal insulation composite material described in this embodiment includes the following raw material components:

[0038]

[0039] The preparation method of the silica thermal insulation composite material described in this embodiment comprises the following steps:

[0040] (1) get the nano-SiO according to the selected ratio 2 Powder, fiber material, binder, additive and rare earth compound are mixed and mixed at high speed;

[0041] (2) Compress the obtained mixture at normal temperature and under a pressure of 1.581MPa-5.5MPa, and then fix and mold it with aluminum foil paper after pressing, and then dry it to obtain the desired thermal insulation composite material.

Embodiment 3

[0043] The silica thermal insulation composite material described in this embodiment includes the following raw material components:

[0044]

[0045]

[0046] The preparation method of the silica thermal insulation composite material described in this embodiment comprises the following steps:

[0047] (1) get the nano-SiO according to the selected ratio 2 Powder, fiber material, binder, additive and rare earth compound are mixed and mixed at high speed;

[0048] (2) Compress the obtained mixture at normal temperature and under a pressure of 1.581MPa-5.5MPa, and after the compression, use aluminum foil to fix and mold it off-line, and dry it to obtain the desired thermal insulation composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com