A method and device for generating an ultrasonic radiation force field for engineering cartilage cultured in vitro

A technology of in vitro culture and ultrasonic radiation, which is applied in the cultivation device of tissue cells/viruses, the method of stress-stimulated microbial growth, and the biochemical cleaning device, etc., can solve the hollow phenomenon of engineered cartilage, the single compound method, and the insufficient mechanical properties of engineered cartilage. and other problems to achieve the effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

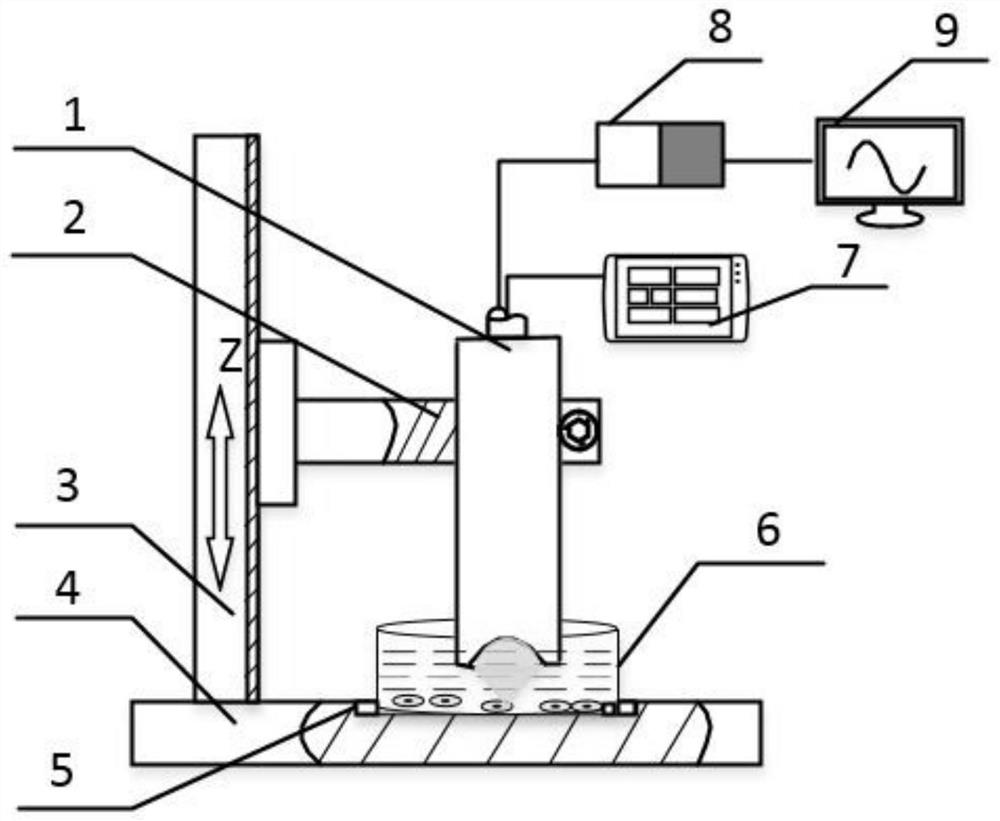

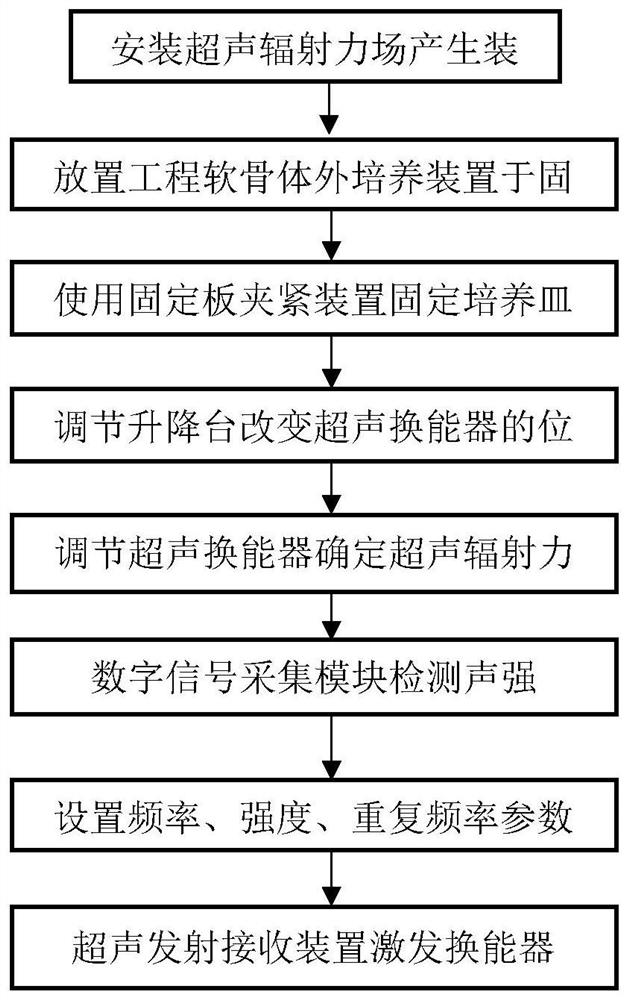

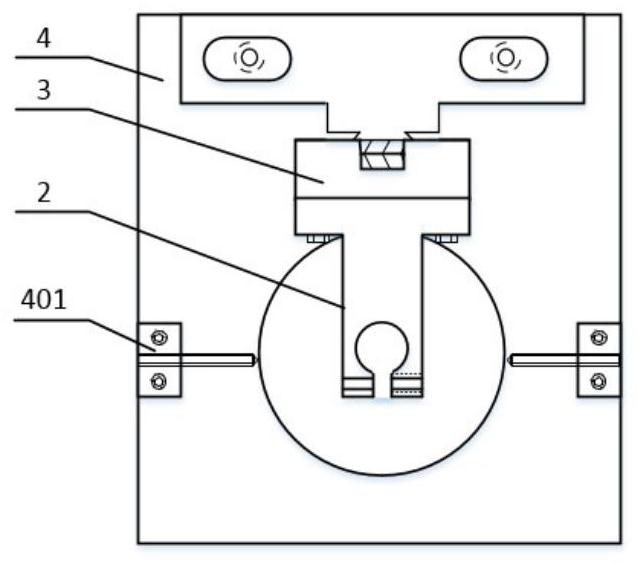

[0053] First, install the lifting platform 3 on the designated position of the fixed base 1, adjust the moving end of the lifting platform 3 to zero position, and manually lock the position of the lifting platform. Then the connecting frame 2 is installed on the moving end of the lifting platform 3 and fixed with a threaded structure. Then install the line-focused ultrasonic transducer 1 on the connecting frame, use the fixing hole on the connecting frame 2 to cooperate with the thread, and lock the line-focused ultrasonic transducer 1 on the connecting frame 2 . The line-focused ultrasonic transducer 1 is connected to the ultrasonic transmitting and receiving device 7 through a cable. Place the prepared engineered cartilage in vitro culture device 6 on the fixed base 4, rotate the engineered cartilage in vitro culture device 6 to determine the direction of the applied ultrasonic radiation force, fix and clamp the engineered cartilage in vitro culture device 6 through the fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com