Preparation and application of a kind of fresh flower fiber filament for textile

A technology for flowers and fibers, applied in the field of materials, can solve the problems of increased process cost, fiber waste, complexity, etc., and achieves the effects of mild conditions, cost reduction, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

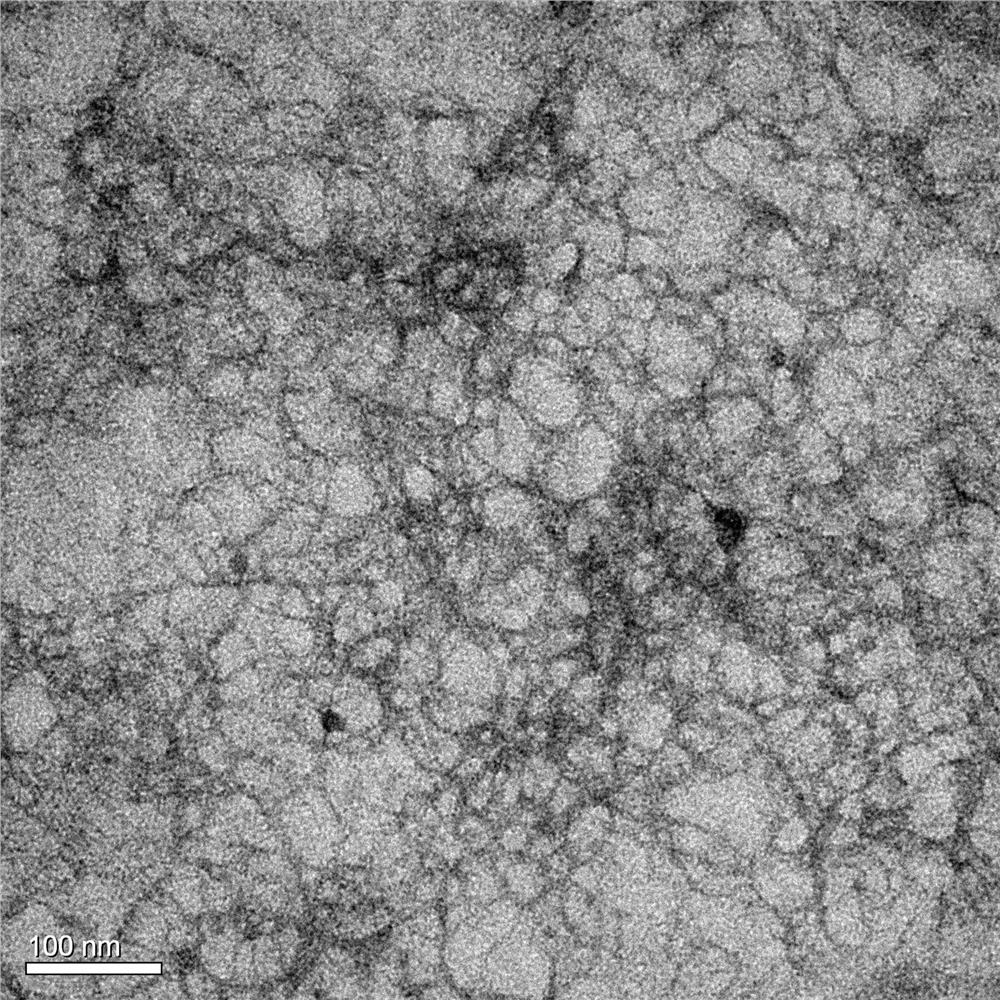

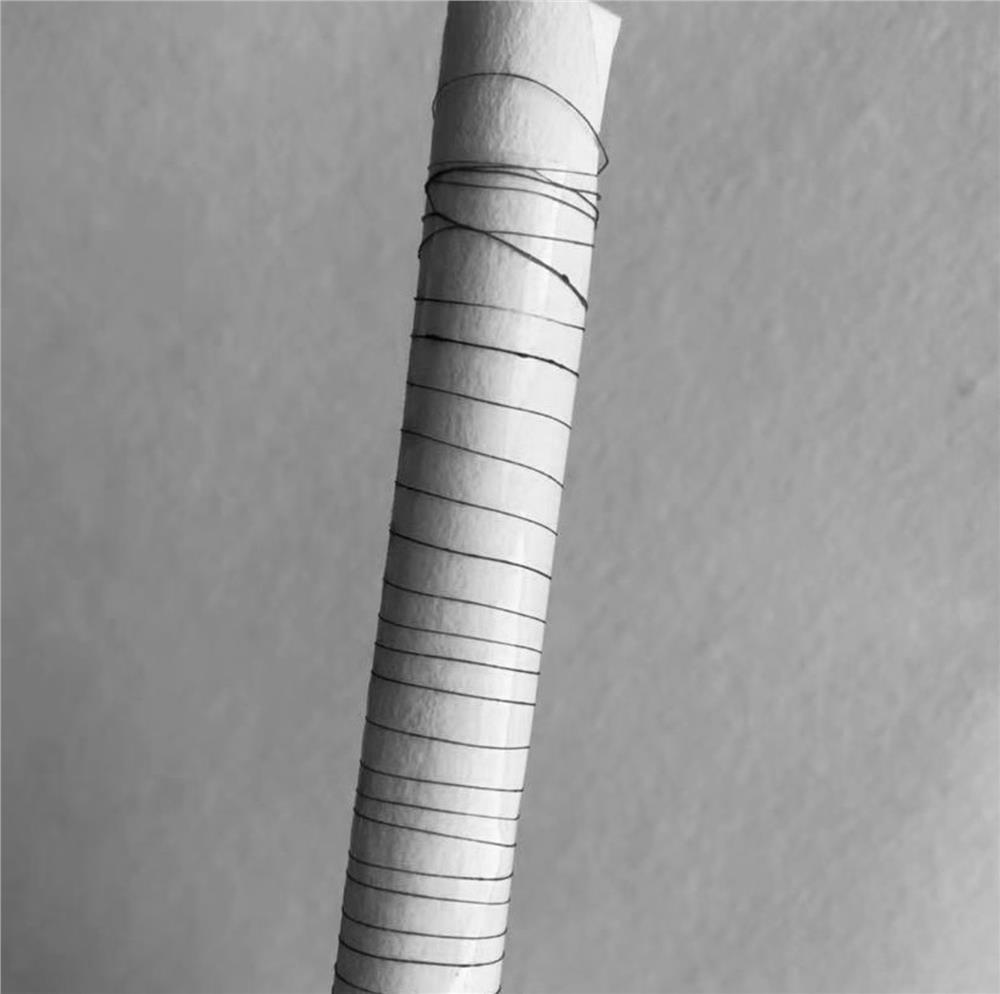

[0026] Take a certain quality of fresh red rose petals, add deionized water equivalent to 1 times the dry weight of the petals, soak for 10 min, pour it into a pulverizer, crush the petals at a speed of 200 rpm for 30 min, and obtain Slurry dispersion. Then the dispersion is poured into a high-pressure homogenizer, and homogenized 20 times at 100 bar to obtain a nano-sized flower fiber dispersion ( figure 2 ). Mix the flower fiber dispersion and sodium alginate in water; wherein, the quality of sodium alginate accounts for 5% of the absolute dry weight of the flower fiber, and the concentration of the spinning solution after preparation is 3%. After vacuum degassing, the spinning solution is injected into a coagulation bath (5% calcium chloride solution), and the obtained flower fiber filaments are collected by a reel, and the red rose fiber can be obtained after air drying. The process of this embodiment is as follows figure 1 as shown, image 3 For the obtained red ros...

Embodiment 2

[0029] Take a certain quality of fresh lily petals, pour them into a pulverizer, and crush them for 1 min at a speed of 2000 rpm to obtain a slurry-like dispersion. Then pour the dispersion into a high-pressure homogenizer, and homogenize it five times at 900 bar to obtain a nano-sized flower fiber dispersion. The flower fiber dispersion and natural guar gum are compounded in water; wherein, the quality of guar gum accounts for 50% of the absolute dry weight of flower fiber, and the concentration of the spinning solution after preparation is 3%. After ultrasonic degassing, the spinning solution was injected into a coagulation bath (1wt% borax solution), and the obtained flower fiber filaments were collected by a reel, and lily flower fibers could be obtained after air-drying. The flow of this embodiment is as follows Figure 4 as shown, Figure 5 Be the lily fiber that this embodiment obtains.

[0030] The fracture stress of the lily fiber is 42.1KPa through the test of the...

Embodiment 3

[0032] Take a certain quality of fresh carnation petals, add deionized water equivalent to 10 times the dry weight of the petals, soak for 16 minutes, pour it into a pulverizer, and crush it at a speed of 700 rpm for 5 minutes to obtain a pulp shaped dispersion. Then pour the dispersion into a high-pressure homogenizer, and homogenize it for 7 times at 300 bar to obtain a nano-sized flower fiber dispersion. The flower fiber dispersion and chitosan were compounded in 2% acetic acid aqueous solution; wherein, the quality of chitosan accounted for 80% of the absolute dry weight of flower fiber, and the concentration of the spinning solution after preparation was 5%. After vacuum degassing, the spinning solution is injected into a coagulation bath (5% sodium hydroxide + 0.5% sodium sulfate solution, or pure water), and the obtained flower fiber filaments are collected by a reel, and the carnation flower fiber can be obtained after air drying.

[0033] The fracture stress of the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com