Production process for improving comfort of blended knitted fabrics

A technology of production technology and comfort, applied in the field of knitted fabric production technology, can solve problems such as poor knitting tension and yarn feeding amount, skewed coils, horizontal and vertical columns, poor recovery of coil shape changes, etc., to achieve Improve the cohesion performance and coverage ability, supplement the expansion and contraction defects, and the effect of not easy to fall apart

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

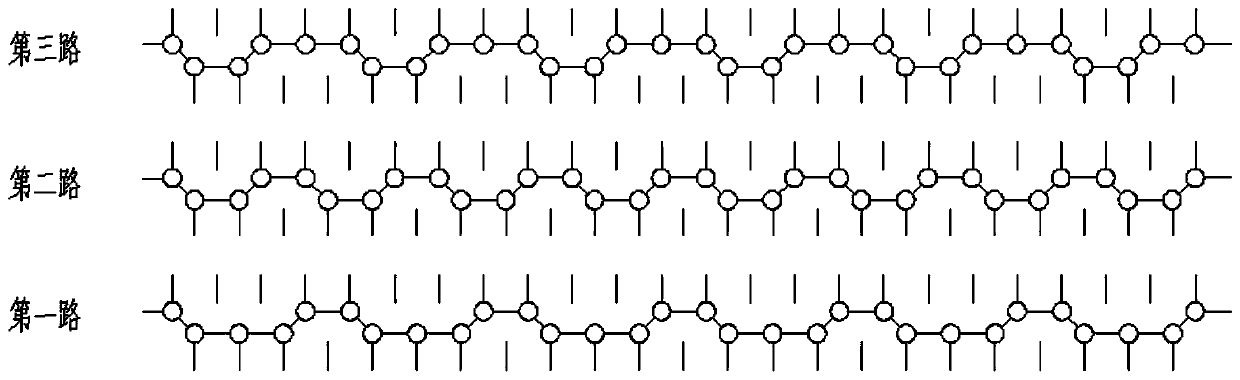

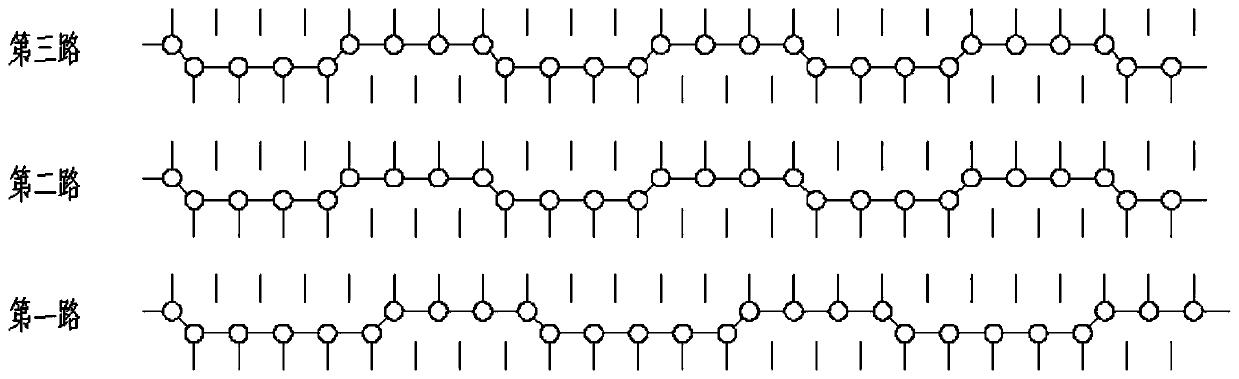

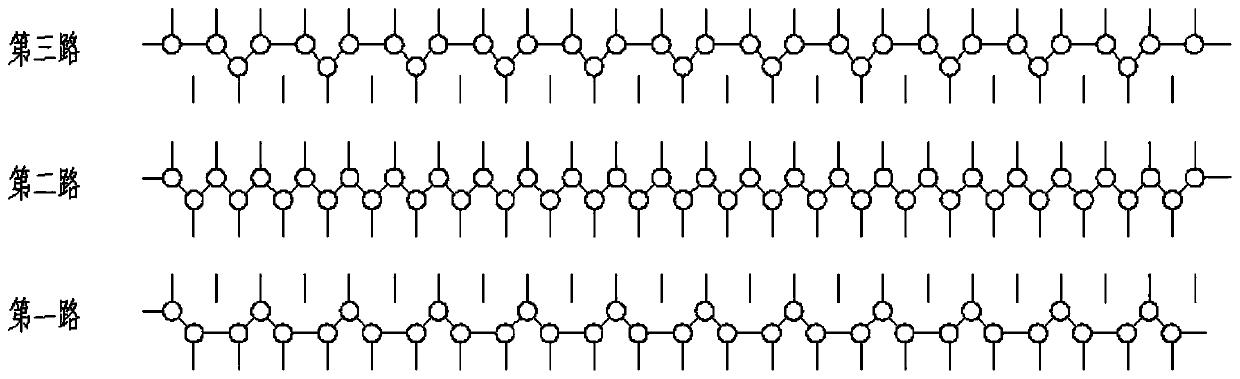

Method used

Image

Examples

Embodiment 1

[0028] A production process for improving the comfort of blended knitted fabrics, the steps are as follows:

[0029] (1) Yarn feeding: The dial and the needle cylinder arranged at 90° on the knitting machine are respectively provided with staggered upper latch needles and lower latch needles, and the blended yarn is transported to the knitting area of the knitting machine. Spun yarn is made by blending polymer spun yarn with wool yarn;

[0030] Polymer spinning is made of dimethyl terephthalate and D-lactide in a mass ratio of 8:1, and after 4 hours of polymerization under the action of dibutyltin dilaurate catalyst, it is passed through a screw extruder at 1350N / cm 2 Under pressure, the temperature of the spinneret is 235°C, and the winding speed is 24m / min under melt spinning and spinning;

[0031] The conveying tension is 25cN, and the blended yarn is sprayed with an antistatic DP305-1 aqueous solution with a mass percentage concentration of 1% before conveying;

[0032...

Embodiment 2

[0042] A production process for improving the comfort of blended knitted fabrics, the steps are as follows:

[0043] (1) Yarn feeding: The dial and the needle cylinder arranged at 90° on the knitting machine are respectively provided with staggered upper latch needles and lower latch needles, and the blended yarn is transported to the knitting area of the knitting machine. Spinning is made by blending polymer spinning with cotton yarn and wool yarn;

[0044] Polymer spinning is made of polyterephthalic acid and D-lactide in a mass ratio of 9:1 under the action of dibutyltin dilaurate catalyst for 4 hours, and then passed through a screw extruder at 1400N / cm 2 Under pressure, the temperature of the spinneret is 232°C, and the winding speed is 25m / min for melt spinning and spinning;

[0045] The conveying tension is 30cN, and the blended yarn is sprayed with an antistatic DP305-1 aqueous solution with a mass percentage concentration of 1% before conveying;

[0046] (2) Back ...

Embodiment 3

[0056] A production process for improving the comfort of blended knitted fabrics, the steps are as follows:

[0057] (1) Yarn feeding: The dial and the needle cylinder arranged at 90° on the knitting machine are respectively provided with staggered upper latch needles and lower latch needles, and the blended yarn is transported to the knitting area of the knitting machine. Spinning is made of polymer spinning blended with cotton, silk and linen;

[0058] Polymer spinning is made of dimethyl terephthalate and D-lactide in a mass ratio of 7:1, and after 4 hours of polymerization under the action of dibutyltin dilaurate catalyst, it is passed through a screw extruder at 1480N / cm 2 Under pressure, the temperature of the spinneret is 239 ° C, and the winding speed is 25 m / min under melt spinning and spinning;

[0059] The conveying tension is 30cN, and the blended yarn is sprayed with an antistatic DP305-1 aqueous solution with a mass percentage concentration of 1% before convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com