A kind of three-dimensional cross-linked super-wetting nanofibrous membrane and its preparation method

A nanofiber membrane and three-dimensional cross-linking technology, which is applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of poor mechanical strength of functional nanofiber membranes and complicated surface functionalization process, and achieve easy industrial production and easy operation and realization, the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Fix the polyvinylidene fluoride nanofiber membrane prepared in the comparative case on the filter device;

[0038] 2) Weigh 0.5g of Span 80 and 0.5g of Span 85 and dissolve them in n-hexane to make a 1 g / L solution;

[0039]3) Pour the obtained solution into an oil-water separation device and filter for 6 h at a filtration rate of 0.1 mL cm -2 min -1 ;

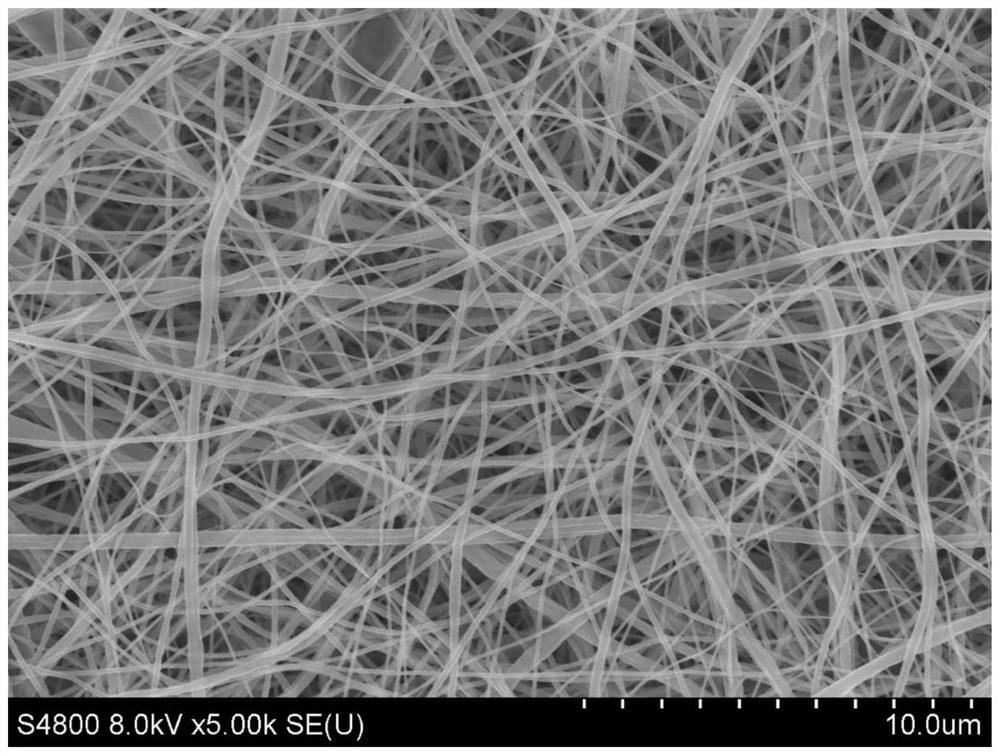

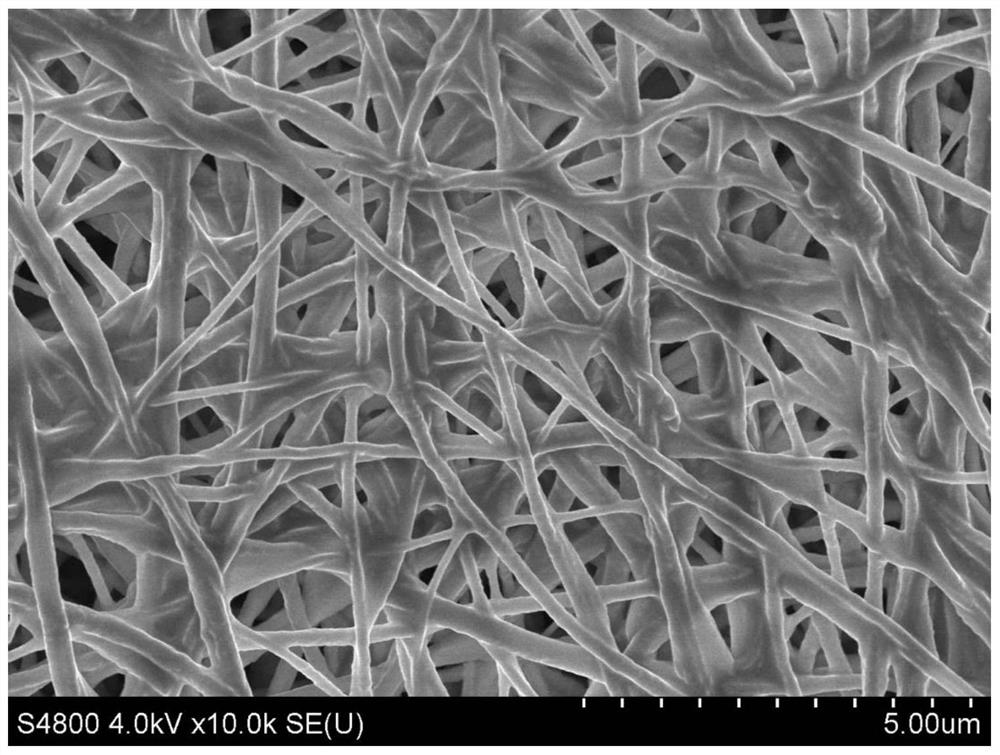

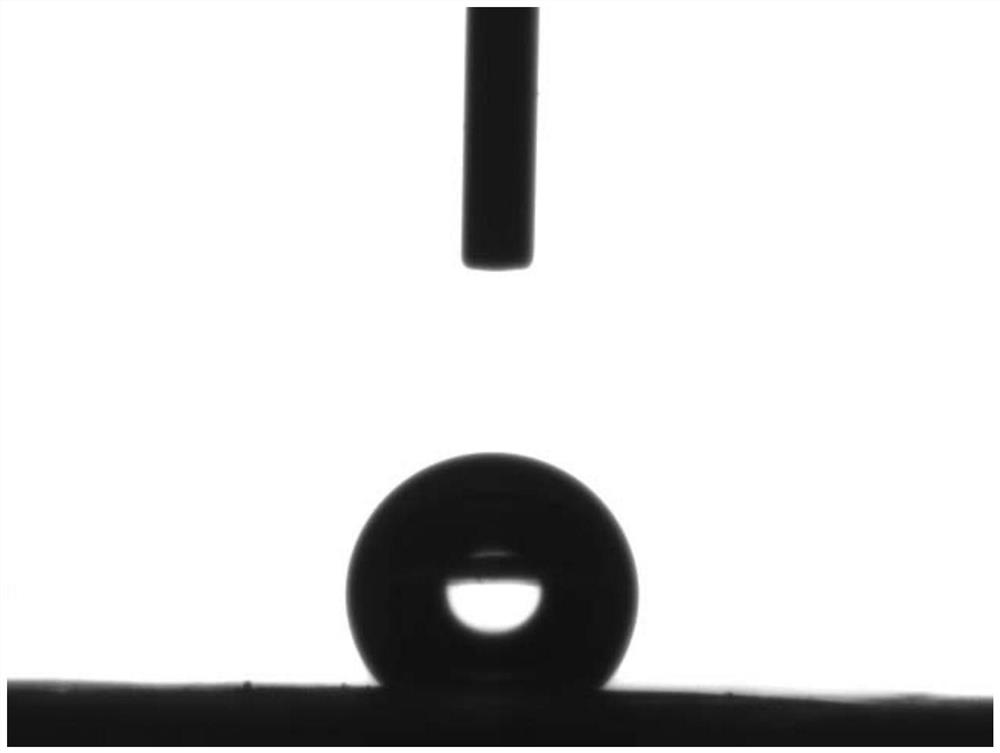

[0040] 4) Remove the nanofiber membrane from the filtration device to obtain a three-dimensional cross-linked superhydrophilic polyvinylidene fluoride nanofiber separation membrane. Such as figure 2 Shown is the surface microscopic topography photo of the obtained separation membrane, the nanofibers and nanofibers of the obtained separation membrane are welded together by crosslinking points, and its tensile strength reaches 8.8 MPa ( Figure 6 shown), the mechanical strength of the nanofibrous membrane prepared by the comparison case is more than 4 times higher, and the contact angle of the nanofibrous membrane...

Embodiment 2

[0042] 1) Preparation of polyacrylonitrile nanofiber membrane by melt spinning method;

[0043] 2) Fix the prepared nanofiber membrane on the filter device;

[0044] 3) Weigh 12g of polyoxyethylene cetyl alcohol and 8g of Tween 80 and dissolve in a mixed solution of water and ethanol (1:1 by volume) to make a 20 g / L solution;

[0045] 4) Pour the prepared solution into the filter device, filter for 5 h, and the filter rate is 20mL·cm -2 min -1 ;

[0046] 5) The nanofiber membrane is removed from the filter device to obtain a three-dimensional cross-linked superhydrophobic polyacrylonitrile nanofiber separation membrane. After testing, the tensile strength of the prepared polyacrylonitrile nanofiber membrane is 5.1 MPa; the contact angle is about 152.3°±2°; The aqueous solution has 61541.2±861.9 L m -2 h -1 bar -1 permeate flux, while the separation efficiency is 99.6%.

Embodiment 3

[0048] 1) Preparation of polyvinylidene fluoride and polytetrafluoroethylene mixed film by electrospinning (the mass ratio of polyvinylidene fluoride and polytetrafluoroethylene is 2:1);

[0049] 2) Fix the prepared mixed nanofiber membrane on the filter device;

[0050] 3) Weigh 21g of sorbitan tristearate and 19g of Span 60 and dissolve them in toluene and acetone (2:3 by volume) to make a 40 g / L solution;

[0051] 4) Pour the obtained solution into the filter device, filter for 3 h, and the filtration rate is 45mL cm -2 min -1 ;

[0052] 5) Remove the nanofiber membrane from the filtration device to obtain a three-dimensional cross-linked superhydrophilic nanofiber hybrid separation membrane. After testing, the tensile strength of the prepared mixed fiber membrane is 15.4 MPa; the contact angle is about 8°, and it drops to 0° within 5 seconds; under the condition of gravity (980 Pa), its resistance to surfactant The stable toluene-in-water emulsion has 46917.7±861.7Lm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com