Method of preparing three-dimensional super-stretchable crystalline nanowire

A nanowire and crystalline technology, applied in the field of preparation of three-dimensional ultra-stretchable crystalline nanowires, can solve the problems of relaxation space reduction, limitation, nanowire breakage, etc., achieve more relaxation space, improve stretchability Stretchability, the effect of good stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

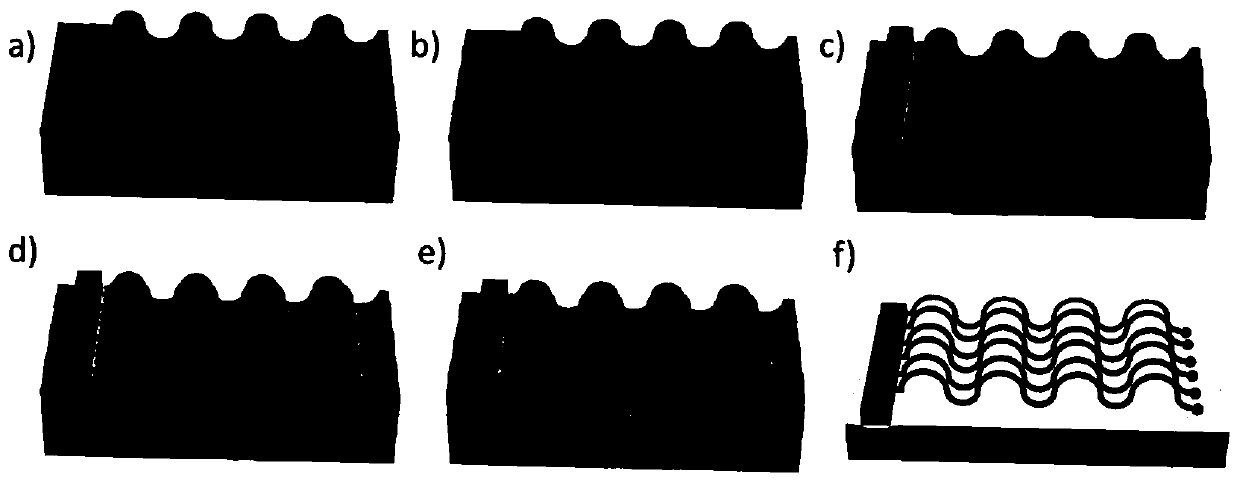

[0027] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with specific implementation examples. The flow chart is as follows figure 1 shown.

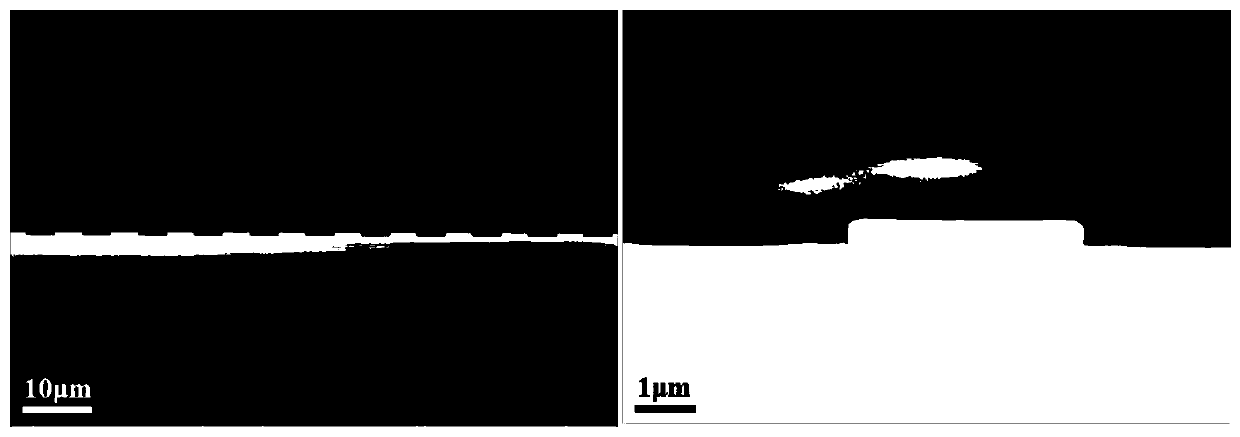

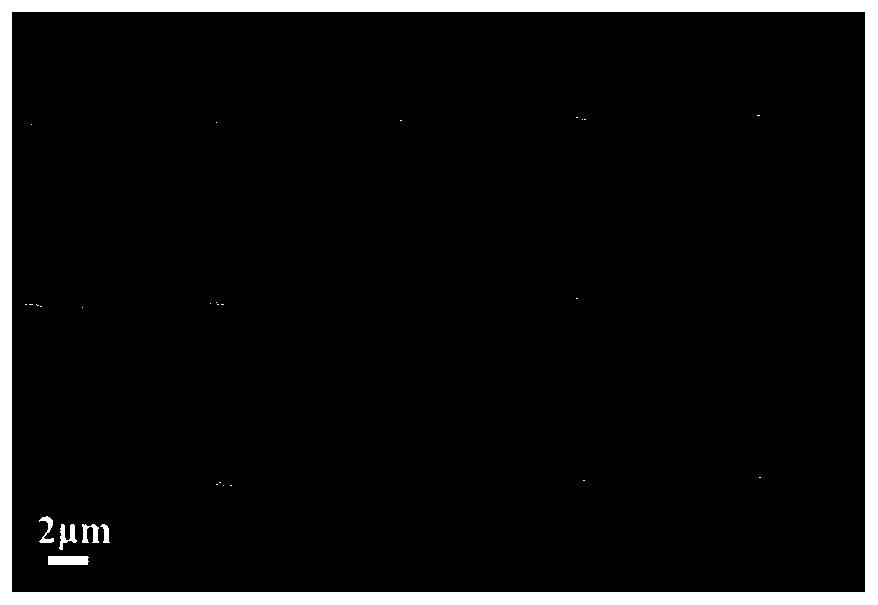

[0028] The steps are as follows: 1) Use silicon wafers, glass, aluminum foil, compounds (such as silicon nitride, silicon oxide, silicon oxynitride), polymers or other metal materials as substrates, and use PECVD or PVD processes to deposit on the substrates An insulating dielectric layer (about 4 μm); 2) Use photolithography, electron beam direct writing or mask technology to define the pattern of the step edge, use inductively coupled plasma (ICP) etching or reactive plasma etching (RIE) The process etches the dielectric layer to form a vertical step sidewall (about 1 μm depth); use ICP or RIE alternate cycle etching method to etch the step structure; first use C in the etching process 4 f 8 、CF 4 , SF 6 Reactive gases wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com