High-silicon content carbon and silicon sandwiched material, preparation method thereof and application in lithium ion battery

A lithium-ion battery, carbon silicon technology, applied in the fields of electrochemistry and energy storage, which can solve problems such as large-scale production and commercialization barriers of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

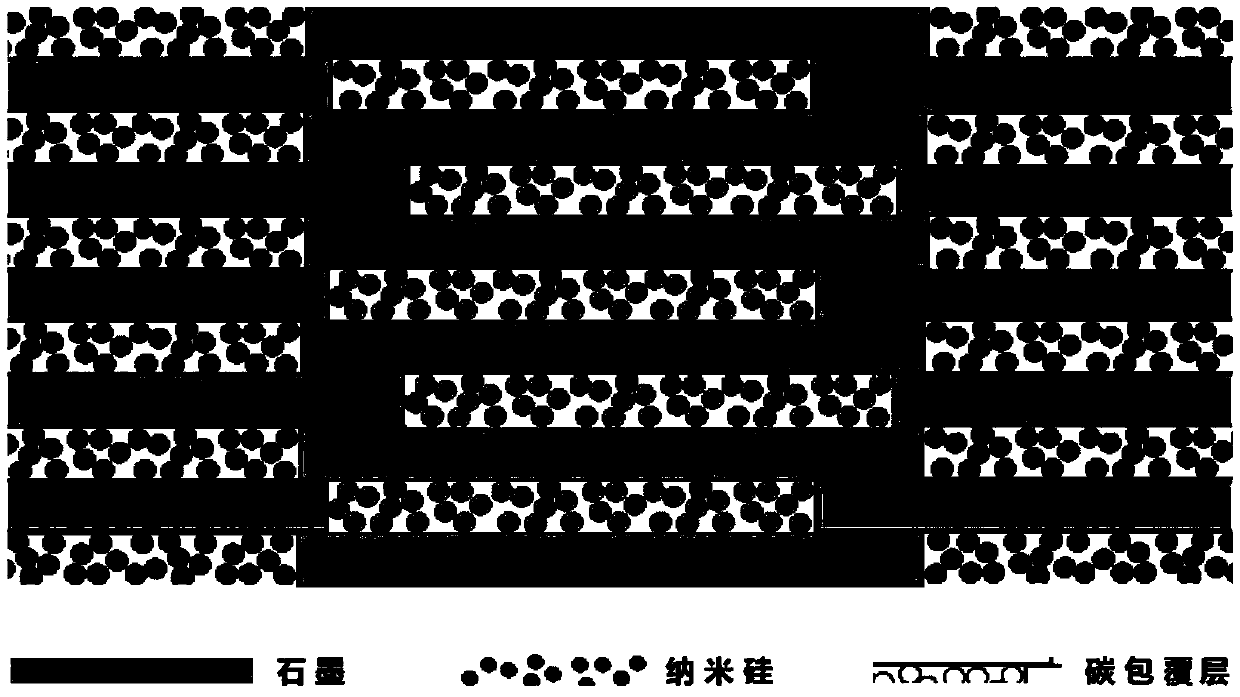

AI Technical Summary

Problems solved by technology

Method used

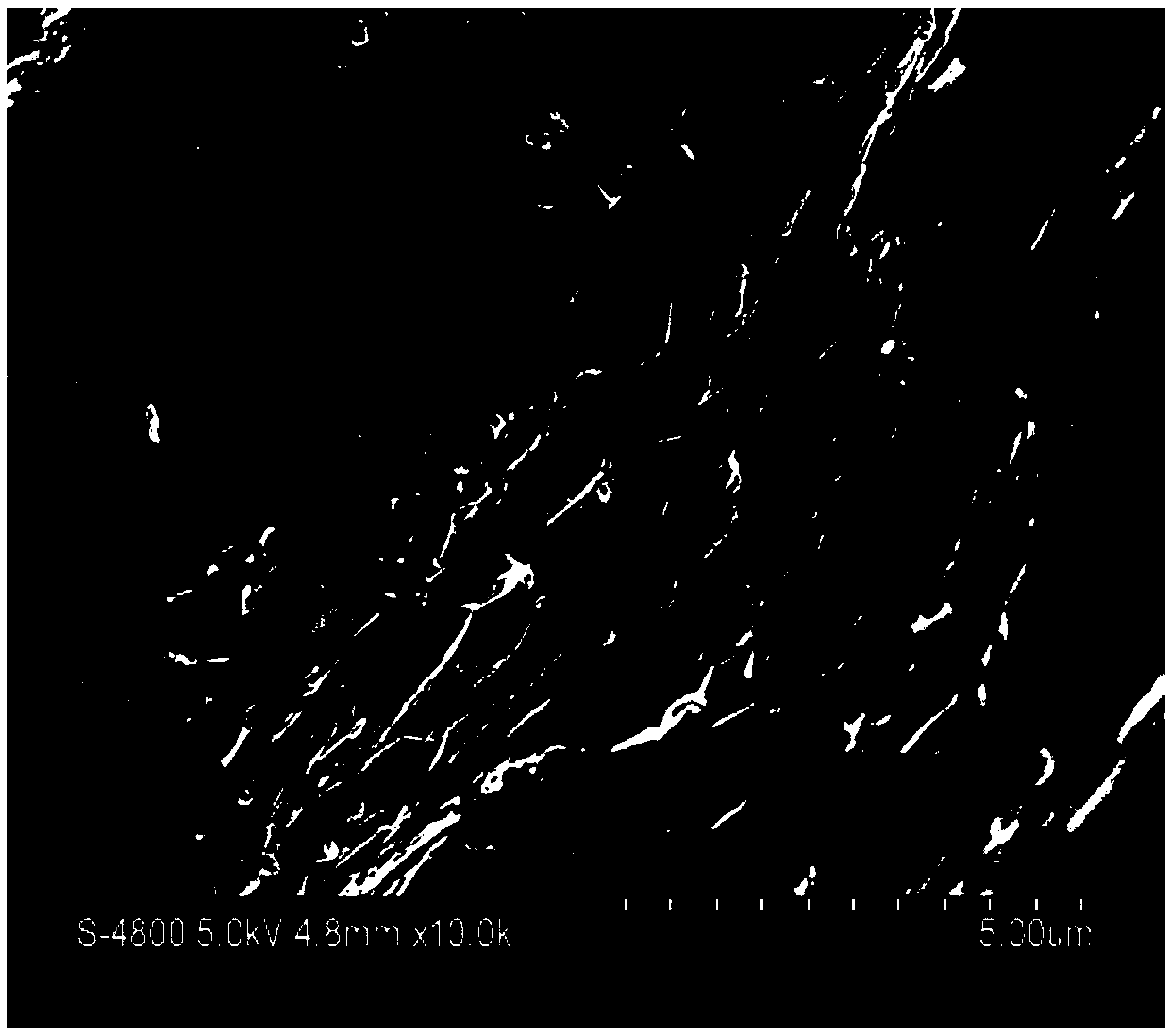

Image

Examples

Embodiment 1

[0070] CS40, a carbon-silicon sandwich negative electrode material with a silicon content of 40wt%, was prepared by the following method:

[0071] (1) Dissolve 0.8kg of PVB in 100L of isopropanol.

[0072] (2) Disperse 10.Kg of silicon nanoparticles (D50=110nm), about 110nm, in the above-mentioned isopropanol solution, and stir evenly for 1h.

[0073] (3) Then add 10kg of flake graphite (D50=3.0μm) and 2.5kg of asphalt into the slurry, and mix thoroughly with a nano-disperser SH156.

[0074] (4) Drying the mixture by rotary vacuum distillation to obtain a preliminary powder mixture.

[0075] (5) Roll the dried mixture with a roller granulator (Changzhou Pioneer Drying Equipment Co., Ltd.) at room temperature; the pressure is controlled at about 18 tons, and the rolling density is 1.4-1.5g / cm 3 . It is then crushed and sieved to obtain particles with a size of <1 mm. The fine powder is then crushed and crushed.

[0076] (6) Treat the particles obtained above at 500° C. und...

Embodiment 2

[0088] CS20, a carbon-silicon sandwich anode material with a silicon content of 20wt%:

[0089] (1) Dissolve 0.17 g of PVB in 50 mL of isopropanol.

[0090] (2) Disperse 2.0 g of silicon nanoparticles (D50=110 nm) in the above-mentioned isopropanol solution, and stir evenly for 1 h.

[0091] (3) Then add 6.0g flake graphite and 2.0g asphalt to the slurry, and mix them well.

[0092] (4) The mixture is dried by distillation under reduced pressure to obtain a preliminary powder mixture.

[0093] (5) Roll the dried mixture at room temperature. The pressure is 16ton / cm 2 , rolling density is 1.6g / cm 3 . It is then crushed and sieved to obtain particles with a size of <1 mm. The fine powder is then crushed and crushed.

[0094] (6) Treat the particles obtained above at 500° C. under an argon atmosphere for 0.5 h to obtain a first precursor.

[0095] (7) Crushing the first precursor and screening to obtain particles with a size of 2-40 μm; they are the second precursor.

[...

Embodiment 3

[0098] CS56, a carbon-silicon sandwich anode material with a silicon content of 56wt%:

[0099] (1) Dissolve 0.17 g of PVB in 50 mL of isopropanol.

[0100] (2) Disperse 5.6 g of silicon nanoparticles (D50=110 nm) in the above-mentioned isopropanol solution, and stir evenly for 1 h.

[0101] (3) Then add 2.4g flake graphite and 2.0g asphalt to the slurry and mix thoroughly.

[0102] (4) The mixture is dried by distillation under reduced pressure to obtain a preliminary powder mixture.

[0103] (5) Roll the dried mixture at room temperature. The pressure is 6ton / cm 2 , rolling density is 1.3g / cm 3 . It is then crushed and sieved to obtain particles with a size of <1 mm. The fine powder is then crushed and crushed.

[0104] (6) Treat the particles obtained above at 500° C. under an argon atmosphere for 0.5 h to obtain a first precursor.

[0105] (7) Crushing the first precursor and screening to obtain particles with a size of 2-40 μm. as the second precursor.

[0106] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com