Preparation method of bio-based electron transport material

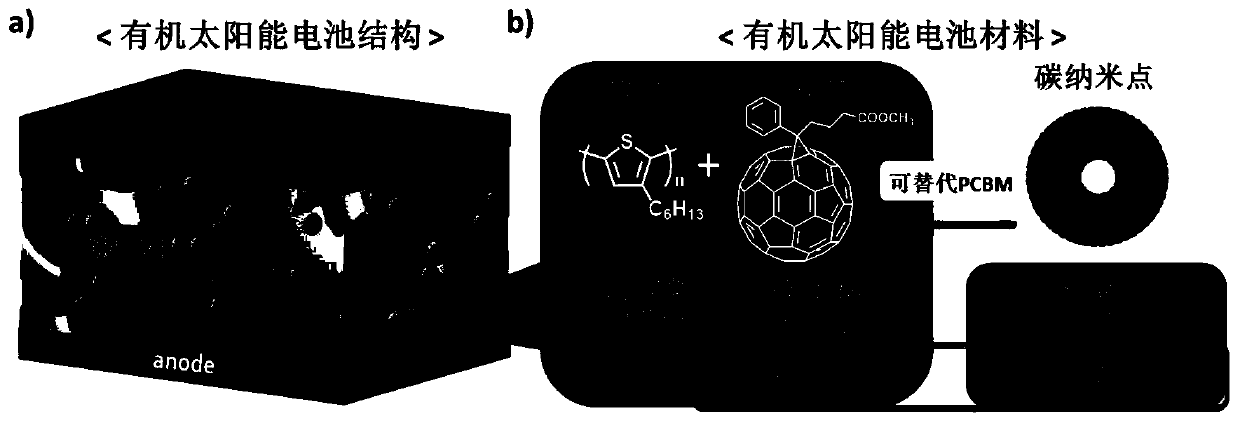

An electron transport material, bio-based technology, applied in the field of preparation of bio-based electron transport materials, can solve problems such as low electron transport efficiency, and achieve the effects of increasing electron cloud density, increasing electron mobility, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of a bio-based electron transport material of the present invention comprises the following steps: put 10g of cellulose, 100mL of acetone, and urea into a reaction kettle, ultrasonically sonicate for 2 minutes, and after the system is evenly mixed, put the reaction kettle into a muffle Furnace, react at 200 ° C, the reaction time is 6 hours, after the reaction is completed, cool down to 20 ° C, filter with suction, separate the large-particle carbides, and distill the reaction solvent under reduced pressure; put the product solution in dichloromethane solvent, use silica gel Separation and purification were carried out by column chromatography (mixture of dichloromethane and ethanol as mobile phase). Finally, under the condition of a vacuum degree of 0.04-0.08 MPa, the solvent is distilled off under reduced pressure to obtain a bio-based carbon nano-dot electron transport material. The synthesis yield is 25%; Measured: the electrical conductivity (e...

Embodiment 2

[0023] A preparation method of a bio-based electron transport material of the present invention comprises the following steps: put 10g of cellulose, 100mL of acetone, and ethylenediamine into a reactor, ultrasonically sonicate for 2 minutes, and after the system is evenly mixed, put the reactor into Muffle furnace, react at 200°C, the reaction time is 8 hours, after the reaction is completed, cool down to 20°C, filter with suction, separate the large-particle carbides, and distill off the reaction solvent under reduced pressure; put the product solution in dichloromethane solvent, Separation and purification were carried out by silica gel column chromatography (a mixture of dichloromethane and ethanol as mobile phase). Finally, under the condition of a vacuum degree of 0.04-0.08 MPa, the solvent is distilled off under reduced pressure to obtain a bio-based carbon nano-dot electron transport material. The synthesis yield is 22%; Measured: the electrical conductivity (electron t...

Embodiment 3

[0025] A preparation method of a bio-based electron transport material of the present invention comprises the following steps: put 10g of starch, 100mL of acetone, and urea into a reaction kettle, ultrasonically sonicate for 2 minutes, and after the system is evenly mixed, the reaction kettle is put into a muffle furnace , react at 200°C, the reaction time is 6 hours, after the reaction is completed, cool down to 20°C, filter with suction, separate the large particles of carbide, and distill the reaction solvent under reduced pressure; put the product solution in dichloromethane solvent, use a silica gel column Separation and purification were carried out by chromatography (mixture of dichloromethane and ethanol as mobile phase). Finally, under the condition of a vacuum degree of 0.04-0.08 MPa, the solvent is distilled off under reduced pressure to obtain a bio-based carbon nano-dot electron transport material. The synthesis yield is 20%; Measured: the electrical conductivity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com