A method, system and application for preparing modified activated carbon by two-stage reduction pyrolysis of organic solid waste

An organic solid and activated carbon technology, applied in the preparation of liquid hydrocarbon mixtures, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of organic solid wastes that cannot be effectively treated, and achieve increased quality, specific surface area, and increased output. Large, highly active effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

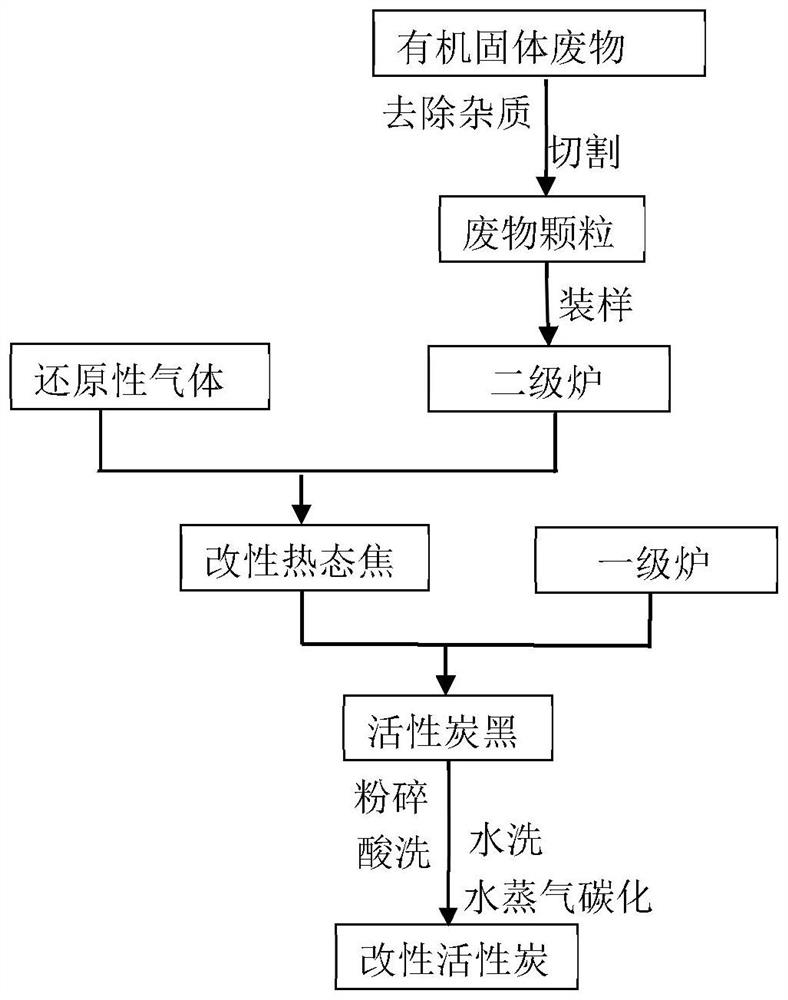

[0029] The method for preparing activated carbon by two-stage pyrolysis of organic solid waste according to the present invention is described in detail by taking waste tires as an example.

[0030] 1) Remove the steel wire from the waste tires and cut them into small pieces (less than 3mm) for easy sample loading. The material ratio of the two-stage pyrolysis furnace is 2:1.

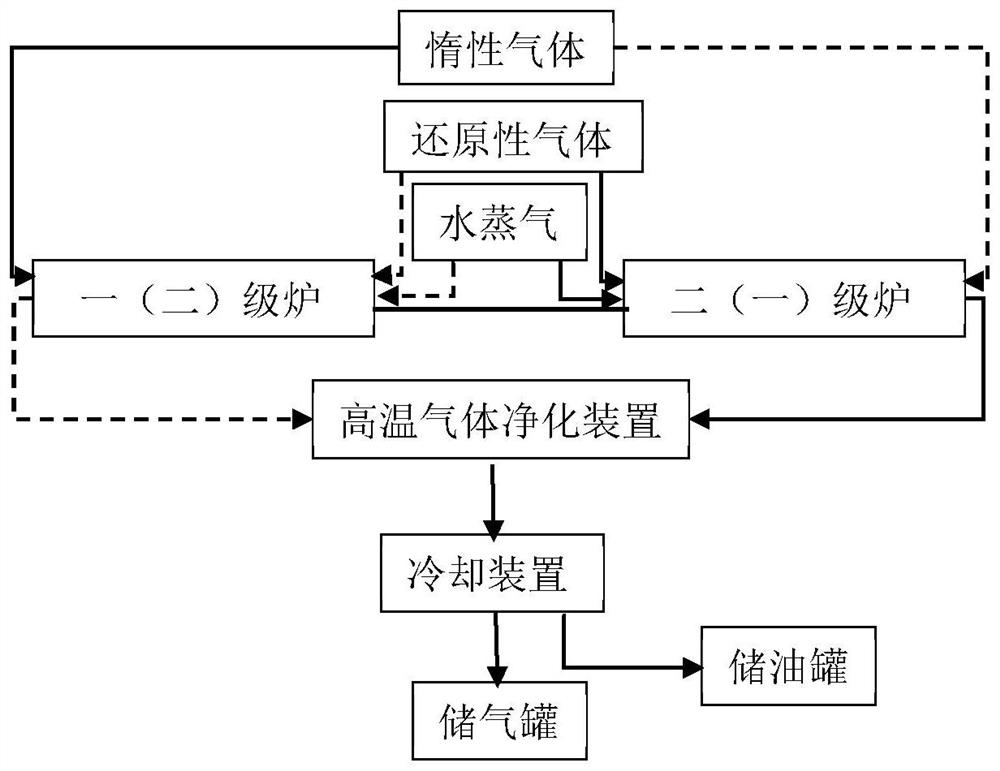

[0031] 2) During the preparation of modified thermal coke, firstly, under the atmosphere of inert gas and reducing gas, the organic solid waste in the secondary furnace is pyrolyzed to prepare modified thermal coke. The mass ratio was 5.0. At a temperature of 600°C, the primary rubber block is pyrolyzed, and the volatile matter of the primary pyrolysis and the secondary activated thermal coke are catalytically reformed to obtain activated carbon black.

[0032] 3) Collect activated carbon black and utilize ball mill to carry out ultrafine grinding and pulverization. Carbon black and 2mol / L acid-base so...

Embodiment 2

[0036] The method for preparing modified activated carbon by two-stage reduction pyrolysis of organic solid waste of the present invention comprises the following steps:

[0037] During the preparation of modified thermal coke, firstly, inert gas and reducing gas (water vapor, CO 2 , NH 3 etc.) atmosphere, the organic solid waste in the secondary furnace is pyrolyzed to prepare modified thermal coke, the pyrolysis temperature is 500°C, and the mass ratio of water vapor to material is 0.01. At a temperature of 450°C, the primary rubber block is pyrolyzed, and the volatile matter of the primary pyrolysis is catalytically reformed with the secondary activated thermal coke to obtain activated carbon black, and the generated cracked oil and cracked gas are stored separately, and the secondary furnace The modified thermal coke inside is reformed into activated carbon black. Finally, the collected activated carbon black is ultrafinely ground and pulverized in a ball mill, first mix...

Embodiment 3

[0039] The method for preparing activated carbon by two-stage pyrolysis of organic solid waste of the present invention comprises the following steps:

[0040] During the preparation of modified thermal coke, firstly, inert gas and reducing gas (water vapor, CO 2 , NH 3 etc.) atmosphere, the organic solid waste in the secondary furnace is pyrolyzed to prepare modified thermal coke, the pyrolysis temperature is 800°C, and the mass ratio of water vapor to material is 2.0. At a temperature of 650°C, the primary rubber block is pyrolyzed, and the volatile matter of the primary pyrolysis is catalytically reformed with the secondary activated thermal coke to obtain activated carbon black. The resulting cracked oil and cracked gas are stored separately, and the secondary furnace The modified thermal coke is reformed into activated carbon black. Finally, the collected activated carbon black is ultra-finely ground and pulverized in a ball mill, firstly mixed with an acid-base solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com