High-temperature-resistant slow-expansion water-absorbing expansion resin plugging aid used in the field of oilfield drilling

A water-swelling, high-temperature-resistant technology, applied in the field of plugging aids, can solve the problems of reduced swelling performance and poor temperature resistance of water-absorbing swellable resins, and achieve the effects of improving pressure bearing capacity, not easy to fall off, and good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

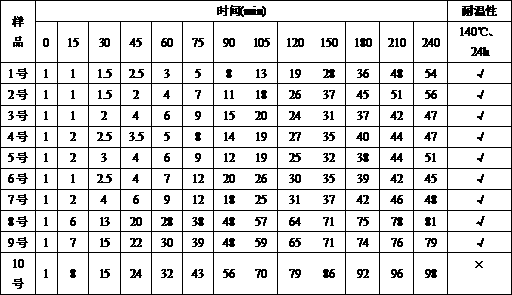

Examples

Embodiment 1

[0025] Put 156.84g of water into a self-made reaction tank, slowly add 13.07g of bentonite while stirring, and after the soil is completely dispersed, add 20.91g of acrylic acid, 52.28g of acrylamide, and 16.21g of 2-acrylamide-2-methylpropane After the sulfonic acid is completely dissolved, pass nitrogen gas for 0.5h at 3°C, and then add 1.3g of cross-linking agent (the mass ratio of triallyl ammonium chloride to N,N-methylenebisacrylamide is 1: 1), 0.78g of sodium sulfite and ammonium persulfate mixed initiator, heated up to 50 ° C for 4 hours, took out and cut into pieces, dried, crushed and granulated, and sieved, leaving 6-10 mesh samples for later use; Fatty acid and 8g of absolute ethanol, slowly warm up to 65°C, after the stearic acid is completely dissolved, add 2g of the above-mentioned 6-10 mesh water-absorbing swelling resin, continue the reaction for 6h, transfer it to a tray, put it in a 45°C oven, The solvent absolute ethanol was removed to obtain a high tempera...

Embodiment 2

[0027] Put 156.84g of water into a self-made reaction tank, slowly add 13.07g of bentonite while stirring, and after the soil is completely dispersed, add 26.14g of acrylic acid, 37.12g of acrylamide, 26.14g of 2-acrylamide-2-methylpropane After the sulfonic acid is completely dissolved, pass nitrogen gas for 1 hour at 5°C, and then add 1.3 g of cross-linking agent (the mass ratio of triallyl ammonium chloride to N,N-methylenebisacrylamide is 4:1) ), 0.78g sodium sulfite and ammonium persulfate mixed initiator, heated up to 70°C for 2 hours, took out and cut into pieces, dried, crushed and granulated, and sieved, leaving 6-10 mesh samples for later use; add 10g stearin to the reactor acid and 10g of absolute ethanol, and slowly warm up to 80°C. After the stearic acid is completely dissolved, add 10g of the above-mentioned 6-10 mesh water-absorbing swelling resin, continue the reaction for 6h, transfer it to a tray, and put it in an oven at 30°C. The solvent is removed by absol...

Embodiment 3

[0029] Put 209.12g of water into a self-made reaction tank, slowly add 10.17g of bentonite while stirring, and after the soil is completely dispersed, add 10.46g of acrylic acid, 20.91g of acrylamide, 10.46g of 2-acrylamide-2-methylpropane After the sulfonic acid is completely dissolved, pass nitrogen gas for 2 hours at 0°C, and then add 0.26 g of cross-linking agent (mass ratio of diallyl ammonium chloride to N,N-methylenebisacrylamide is 1:1) ), 0.026g sodium sulfite and ammonium persulfate mixed initiator, heated up to 30°C for 5h reaction, took out and cut into pieces, dried, pulverized, granulated and sieved, leaving 6-10 mesh samples for later use; add 10g stearin to the reactor acid and 30g of absolute ethanol, slowly warming up to 77°C, after the stearic acid is completely dissolved, add 20g of the above-mentioned 6-10 mesh water-absorbing swelling resin, continue the reaction for 1.5h, transfer it to a tray, and put it in an oven at 55°C, The solvent absolute ethanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com