Graphene-based conductive hydrogel and its preparation method and its application in flexible wearable sensors

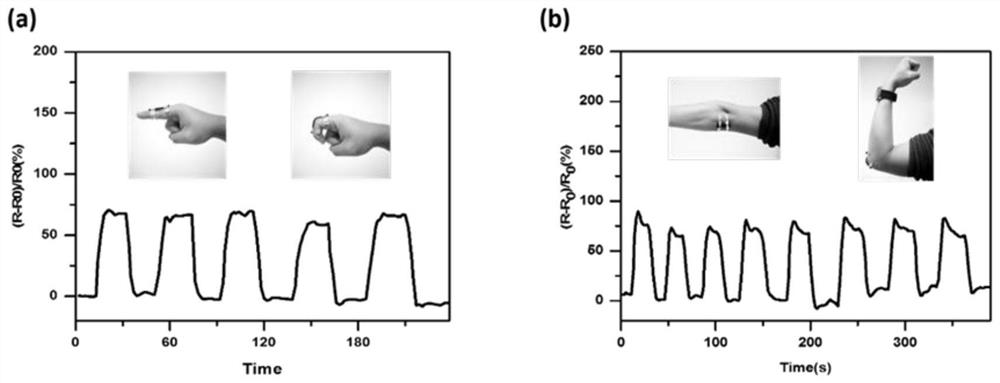

A conductive hydrogel, graphene-based technology, applied in sensors, applications, diagnostic recording/measurement, etc., can solve problems such as high cost, limited application potential of wearable devices, complexity, etc., to reduce complexity and achieve good self-healing The effect of combining performance and reducing measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of graphene-based hydrogel

[0030] To prepare graphene-based hydrogels, follow these steps:

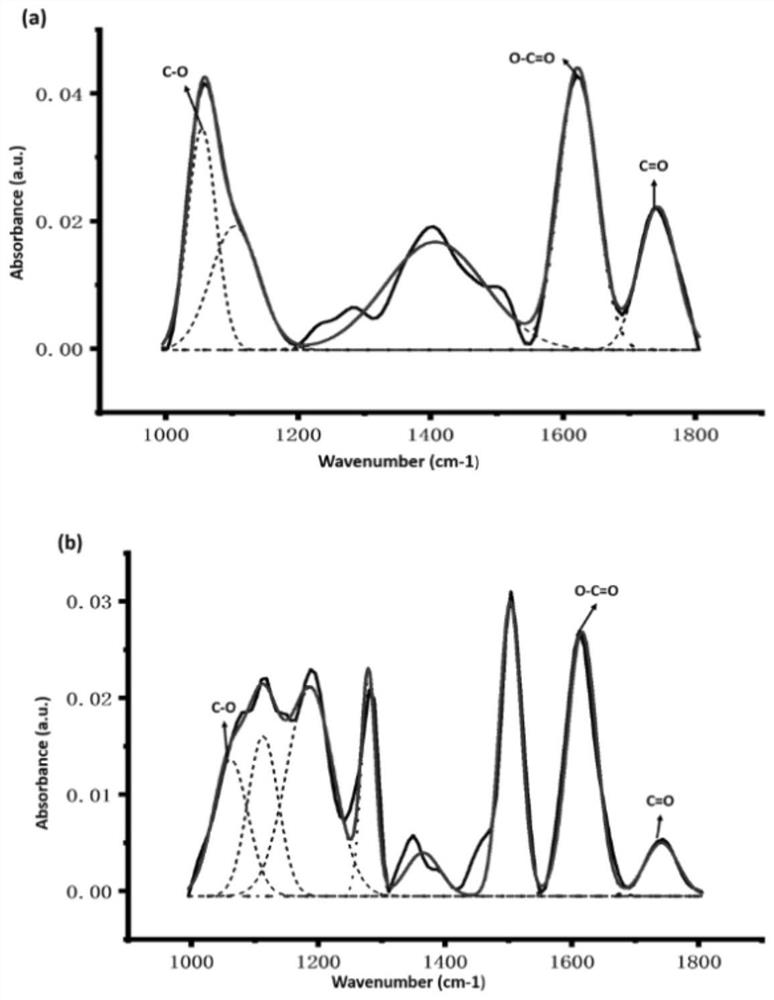

[0031] (1) 30mg graphene oxide is dispersed in the deionized water of 10ml, after ultrasonic dispersion 40min, form homogeneous graphene oxide suspension, the dopamine hydrochloride of 15mg is added in this suspension, adjust pH to 11 with 1Mmol NaOH solution , continue stirring at 70 °C for 2 h, the graphene oxide in the solution is partially reduced to reduced graphene oxide, and a mixed solution of reduced graphene oxide conductive nano-fillers is obtained, figure 1The peak-splitting results of the Fourier transform spectrum can show that the content of oxygen-containing functional groups in graphene oxide is reduced, and graphene oxide is partially reduced to reduced graphene oxide.

[0032] (2) Dissolve 0.25g of sodium alginate with 10ml of deionized water. When dissolving sodium alginate, it is necessary to pre-soak sodium alginate for 8 hours, and...

Embodiment 2

[0034] To prepare graphene-based hydrogels, follow these steps:

[0035] (1) 10mg graphene oxide is dispersed in the deionized water of 10ml, after ultrasonic dispersion 40min, form homogeneous graphene oxide suspension, the dopamine hydrochloride of 5mg is added in this suspension, adjust pH with the NaOH solution of 1Mmol to 9. Continuously stirring at 60° C. for 1 h, the graphene oxide in the solution is partially reduced to reduced graphene oxide to obtain a mixed liquid of reduced graphene oxide conductive nano-filler.

[0036] (2) Dissolve 0.1 g of sodium alginate in 10 ml of deionized water, add 1.0 g of acrylamide monomer to the solution and mix to obtain a flexible base solution, add the reduced graphene oxide in step (1) to the flexible base solution to conduct electricity The nano-filler mixed solution was fully and vigorously stirred (50° C. at 700 rpm for 5 hours), and then allowed to stand for 2 hours in a vacuum drying oven. Take out, under ice bath conditions,...

Embodiment 3

[0038] To prepare graphene-based hydrogels, follow these steps:

[0039] (1) 50mg graphene oxide is dispersed in the deionized water of 10ml, after ultrasonic dispersion 40min, form homogeneous graphene oxide suspension, the dopamine hydrochloride of 25mg is added in this suspension, adjust pH to 12, at 80 ℃ Stirring is continued for 6 h, and the graphene oxide in the solution is partially reduced to reduced graphene oxide to obtain a mixed liquid of reduced graphene oxide conductive nano-filler.

[0040] (2) Dissolve 0.4 g of sodium alginate with 10 ml of deionized water, add 3 g of acrylamide monomer to the solution and mix to obtain a flexible base solution, add the reduced graphene oxide conductive nanometer in step (1) to the flexible base solution The filler mixed solution was fully and vigorously stirred (stirring at 1000 rpm for 6 hours at 70° C.), and then allowed to stand for 8 hours in a vacuum drying oven. Take out, under ice bath condition, add 0.06g ammonium per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com