Porous Cu7S4/Cu (OH)2 composite nanofiber material and preparation method thereof

A technology for composite nanofibers and composite materials, which is applied in the field of preparation of inorganic nanomaterials, can solve the problems of difficulty in preparation and production, time-consuming and energy-consuming, process difficulties, etc., and achieves the effects of low cost, simple production process and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1. Mix 92ml deionized water and 8ml ethylene glycol and stir thoroughly. Weigh 2.131g of copper chloride dihydrate and 0.1625g of thiourea into 50ml of the above-mentioned mixed solution, and stir thoroughly to obtain a solution of 0.25mol / L copper chloride and 0.043mol / L thiourea.

[0021] Step 2, the thiourea solution is directly poured into the stirring cupric chloride solution. White flocs appeared in the solution immediately. After standing at room temperature for 24 hours, the white floc product was filtered, washed with deionized water, and dried at 50°C.

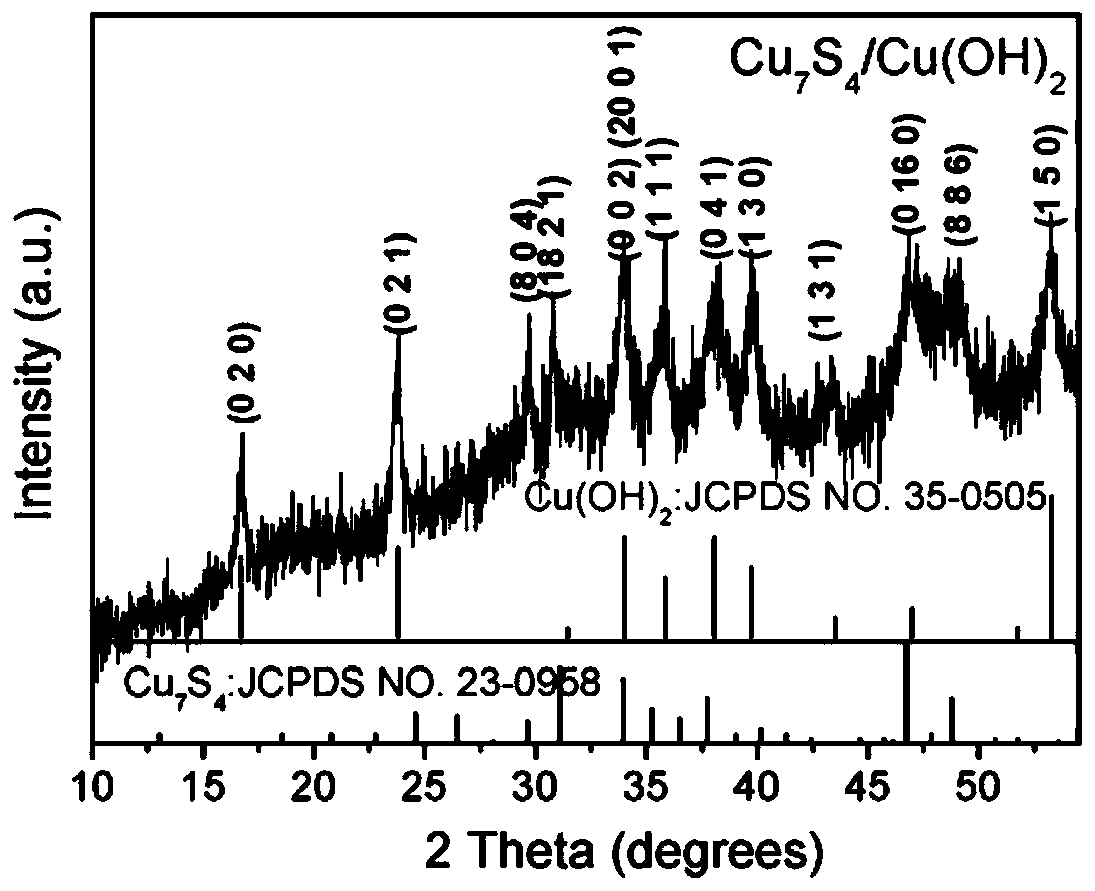

[0022] Step 3, soak the product obtained in step 2 in 2mol / L KOH strong alkali solution for 10 minutes to obtain black Cu 7 S 4 / Cu(OH) 2 . electron microscope ( figure 1 ) shows that it is a nanoporous fiber with a diameter of 79nm. figure 2 For the prepared Cu 7 S 4 / Cu(OH) 2 The composite nanofiber transmission electron microscope photo shows its porous structure; the measured specific surfa...

Embodiment 2

[0024] Step 1. Mix 150ml deionized water and 30ml ethylene glycol and stir well. Weigh 2.131g of copper chloride dihydrate and 0.32g of thiourea into 90ml of the above-mentioned mixed solution, and stir thoroughly to obtain a solution of 0.14mol / L copper chloride and 0.047mol / L thiourea.

[0025] Step 2, the thiourea solution is directly poured into the stirring cupric chloride solution. White flocs appeared in the solution immediately. Stand at room temperature for 10 hours, filter the white floc product, wash with deionized water, and dry at 40°C.

[0026] Step 3, soak the product obtained in step 2 in a 6mol / L KOH strong alkali solution for 10 minutes to obtain Cu 7 S 4 / Cu(OH) 2. Under the electron microscope, it can be seen as a nanoporous fiber with a diameter of 82nm, and the XRD measurement results show that it is Cu 7 S 4 and Cu(OH) 2 Nanocrystalline composition. Its specific surface area is 132.8m 2 / g, the pore volume is 0.257cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com