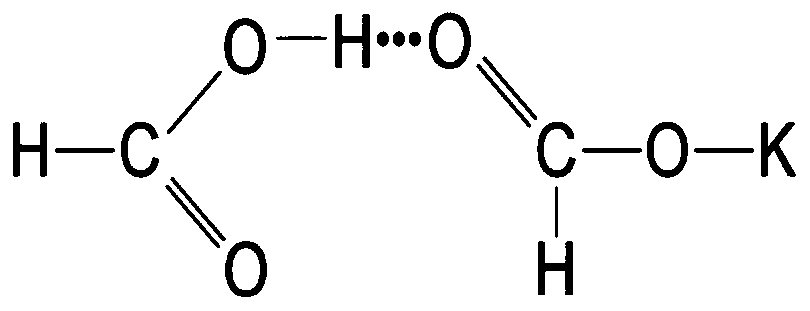

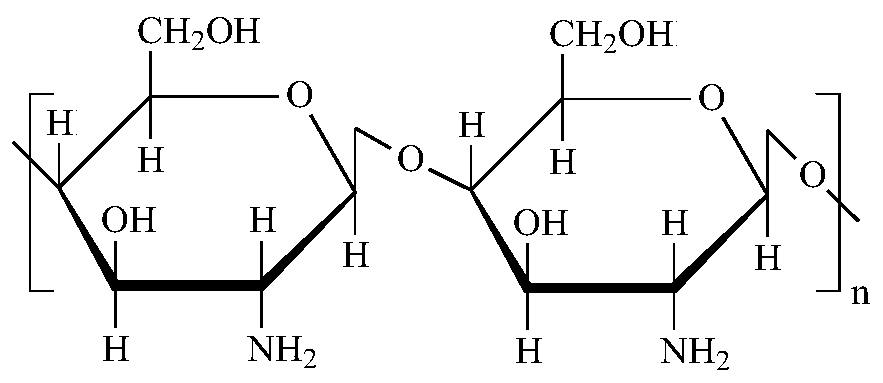

Preparation method of green chitosan/carboxymethyl cellulose/P-type molecular sieve/potassium diformate slow-release antibacterial microspheres

A molecular sieve and slow-release technology, which is applied to medical preparations of non-active ingredients, active ingredients of anhydrides/acids/halides, antibacterial drugs, etc., can solve the problems of inability to reach the end of the intestinal tract, rapid decomposition, etc., and achieve good The effect of exploiting prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

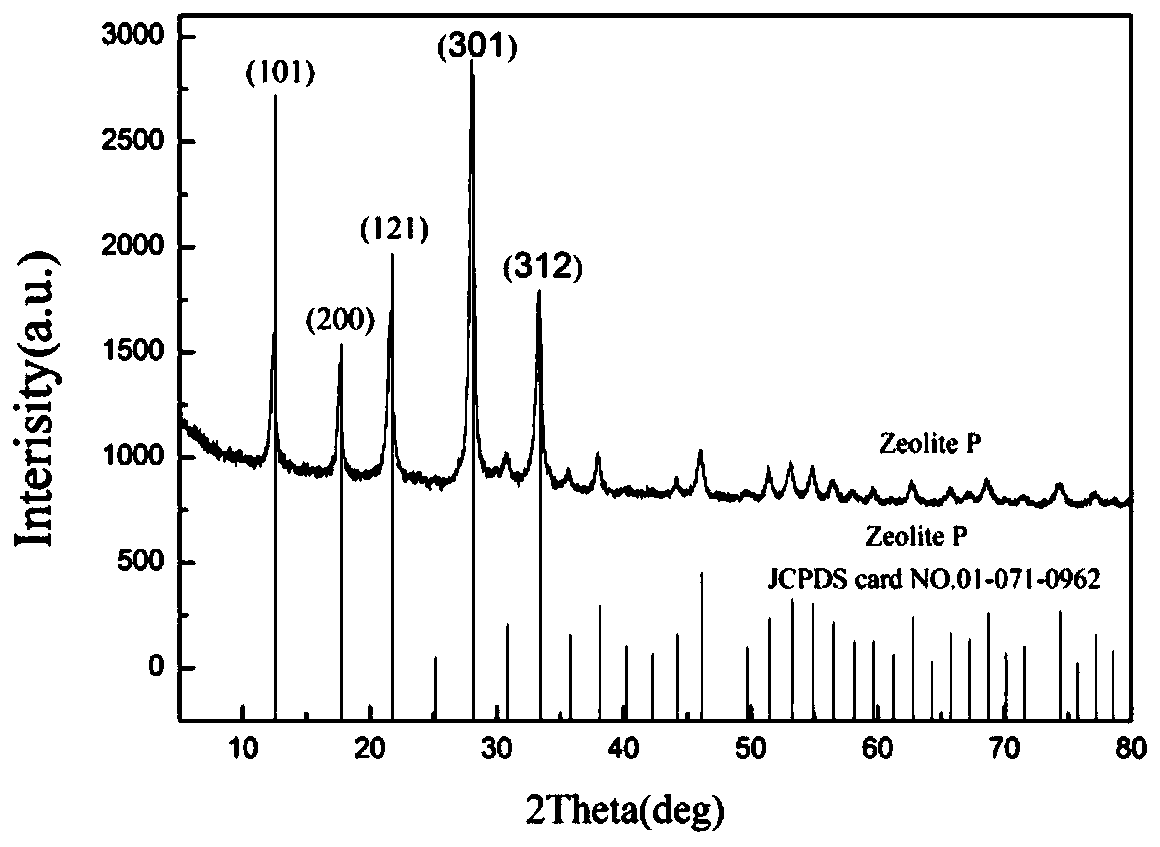

[0026] The stilbene was crushed to 140 meshes, mixed with 12% hydrochloric acid and stilbene at a liquid-solid ratio of 3:1, and stirred at 85° C. for 2 hours. To destroy the structure of stilbite to form some amorphous substances, and remove useless mineral impurities, the acidified zeolite can be used as a precursor for the preparation of molecular sieves; 2g of zeolite precursor is mixed with 50ml NaOH of 1.5 molar concentration, and stirred at a constant temperature of 85°C for 15min , the product was centrifuged for 15min, and the supernatant was taken for subsequent use; 50ml of the supernatant was taken, and the 2 / Al 2 o 3 )=1, n(Na 2 O / SiO 2 )=1.5, n(H 2 O / Na 2 (0)=35 molar ratio proportioning completes the phase proportioning of preparing molecular sieve. The reaction temperature is controlled at 90°C, the reaction time is 6.3 hours, the hydrothermal crystallization temperature and crystallization time are well controlled, and the product is centrifuged, washed...

Embodiment 2

[0028] The stilbene was crushed to 150 meshes, mixed with 13% hydrochloric acid and stilbene at a liquid-solid ratio of 3:1, and stirred at 88° C. for 2.2 hours. To destroy the structure of stilbite to form some amorphous substances, and remove useless mineral impurities, the acidified zeolite can be used as a precursor for the preparation of molecular sieves; 2.1g of zeolite precursor is mixed with 50ml NaOH of 1.7 molar concentration, and the temperature is 83°C Stir for 17min, centrifuge the product for 17min, take the supernatant for later use; take 50ml of the supernatant, 2 / Al 2 o 3 )=3, n(Na 2 O / SiO 2 )=1.5, n(H 2 O / Na 2 (0)=36 molar ratio proportioning completes the phase proportioning of preparing molecular sieve. The reaction temperature was controlled at 91°C, the reaction time was 6.4 hours, the hydrothermal crystallization temperature and crystallization time were well controlled, and the product was centrifuged, washed, and dried to obtain a P-type molecul...

Embodiment 3

[0030]The stilbene was crushed to 160 meshes, mixed with 14% hydrochloric acid and stilbene at a liquid-solid ratio of 3:1, and stirred at 90° C. for 2.5 hours. To destroy the structure of stilbite to form some amorphous substances, and remove useless mineral impurities, the acidified zeolite can be used as a precursor for the preparation of molecular sieves; 2.2g of zeolite precursor is mixed with 50ml NaOH of 2.0 molar concentration, and the temperature is 85°C Stir for 20min, centrifuge the product for 18min, take the supernatant for later use; take 50ml supernatant, 2 / Al 2 o 3 )=5, n(Na 2 O / SiO 2 )=1.6, n(H 2 O / Na 2 (0)=37 molar ratio proportioning completes the phase proportioning of preparing molecular sieve. The reaction temperature is controlled at 92°C, the reaction time is 6.5 hours, the hydrothermal crystallization temperature and crystallization time are well controlled, and the product is centrifuged, washed, and dried to obtain a P-type molecular sieve. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com