Piezoelectric nano composite material and preparation method thereof

A nano-composite material and composite material technology, which are applied in the field of piezoelectric nano-composite materials and their preparation, can solve the problems of increasing patient trauma and pain, unfavorable observation of injured parts, and no developing tracer, etc. MRI and X-Ray dual imaging effect, MRI imaging tracer function enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] 1.1 Sample preparation

[0079] (1) Preparation of piezoelectric composite materials

[0080] S1, weigh Ti(OC 4 h 9 ) 4 Place in a beaker, add absolute ethanol, and mix thoroughly on a magnetic stirrer to obtain Ti(OC 4 h 9 ) 4 solution (wherein, Ti(OC 4 h 9 ) 4 The volume fraction is 50%); then add ammonia water-deionized water mixture dropwise (ammonia water: volume ratio of deionized water=1:5), add dropwise while stirring, Ti(OC 4 h 9 ) 4 The volume ratio of the solution to the ammonia-water mixture is 1:1, Ti(OC 4 h 9 ) 4 Hydrolysis occurs to form a white sol.

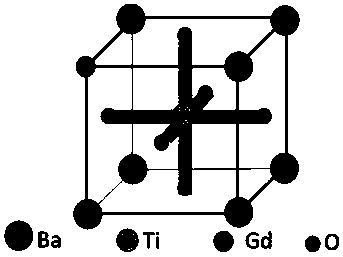

[0081] S2. Place the sol obtained in step S1 on a constant temperature heating magnetic stirrer, set the temperature at 90°C, and slowly add Gd(NO 3 ) 3 ·6H 2 O solution (5% mass fraction) and Ba(OH) 2 ·8H 2 O solution (mass fraction is 50%), fully stirred and mixed evenly under normal pressure to obtain a mixed solution.

[0082] Among them, Ba(OH) 2 ·8H 2 O input according to the sto...

Embodiment 2

[0113] According to the preparation process of the piezoelectric composite material in Example 1, the difference is that the Gd(NO 3 ) 3 ·6H 2 O addition ratio, the product 0.8Gd-BTO / PLGA was obtained.

[0114] Test the piezoelectric properties of the product obtained according to the test method in Example 1, and compare with the piezoelectric properties of the product in Example 1, the results are shown in Table 2.

[0115] Table 2 Test results of piezoelectric properties

[0116] PLGA BTO / PLGA 0.025Gd-BTO / PLGA 0.8Gd-BTO / PLGA Piezoelectric constant D33, pC N -1

[0117] It can be seen from the test results in Table 2 that Gd 3+ When the doping amount is high, the piezoelectric properties of the material will be reduced.

Embodiment 3

[0119] Gd-BTO nanoparticles were prepared according to the preparation process of Example 1, except that in step S3, the reaction time was 72 h.

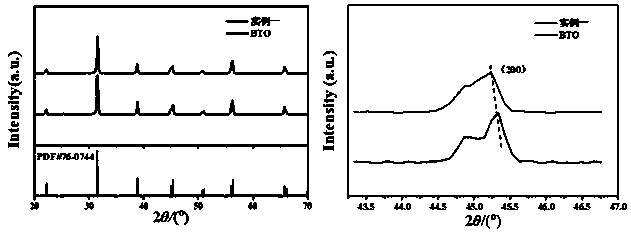

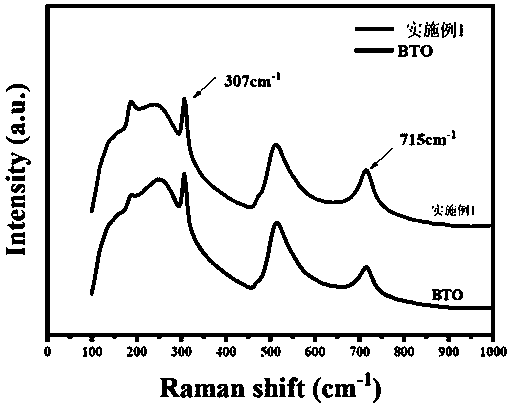

[0120] Gained nanoparticles are tested and calculated for unit cell parameters and compared with the nanoparticles of Example 1, the results are shown in Table 3.

[0121] Table 3 Calculation results of unit cell parameters

[0122] Time(h) a / nm c / nm c / a △2θ(o) Example 3 72 4.0126 4.0217 1.0023 0.173 Example 1 120 4.0056 4.0232 1.0044 0.287

[0123] It can be seen from the calculation results in Table 3 that with the prolongation of the reaction time, the c / a value and the Δ2θ value all increase, which proves that the tetragonal phase content in the product increases with the prolongation of the reaction time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com