Silicon-based negative electrode material for lithium ion battery and preparation thereof, negative electrode sheet and secondary battery

A silicon-based negative electrode material, lithium-ion battery technology, applied in secondary batteries, battery electrodes, negative electrodes, etc., can solve the problems of uneven distribution of composite silicon, no research on negative electrode materials for lithium-ion batteries, and high carbonization temperature. , to achieve the effects of favorable cost control, commercialization and popularization, excellent cycle stability and rate performance, and simple reaction method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

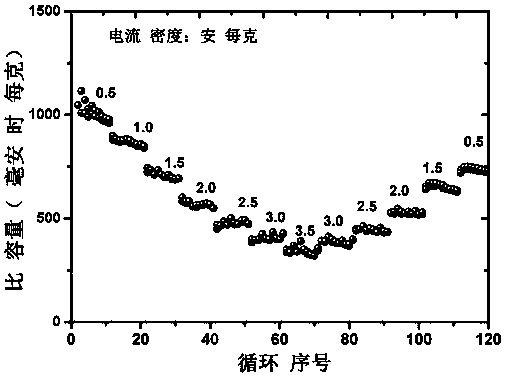

[0038] 1 g of glucose was dissolved in 20 mL of deionized water to form a solution, and then 0.4 g of tin acetate (C 4 h 6 o 4 Sn), followed by the addition of 0.6 g of diatomaceous earth (80–100 nm), glucose was used as a carbon precursor in this experiment. After that, the solution was put into a centrifuge and stirred for 10 h. After the centrifugal stirring, the solution was put into a freeze dryer to freeze for 2 h, and then dried for 8 h. The freeze-dried product was carbonized at a high temperature of 500 °C for 4 h, and after naturally falling to room temperature, the target product C-SiO was finally obtained. x -Sn. Mix the prepared tin-coated silicon oxide active material, conductive carbon black, and binder polyvinylidene fluoride uniformly in a mass ratio of 8:1:1, and use 1-methyl-2-pyrrolidone as a solvent to prepare negative electrode slurry material, which was coated on a copper foil to make a negative electrode sheet, and dried overnight at 50 °C. The ele...

Embodiment 2

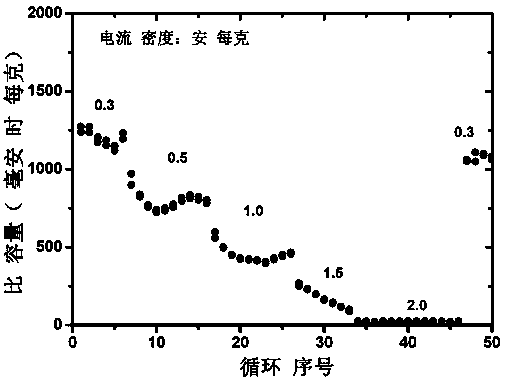

[0040] 1 g of glucose was dissolved in 20 mL of deionized water to form a solution, and then 0.3 g of tin acetate (C 4 h 6 o 4 Sn), followed by the addition of 0.7 g of diatomaceous earth (80–100 nm), glucose was used as a carbon precursor in this experiment. After that, the solution was put into a centrifuge and stirred for 10 h. After the centrifugal stirring, the solution was put into a freeze dryer to freeze for 2 h, and then dried for 8 h. The freeze-dried product was carbonized at a high temperature of 500 °C for 4 h, and after naturally falling to room temperature, the target product C-SiO was finally obtained. x -Sn. Mix the prepared tin-coated silicon oxide active material, conductive carbon black, and binder polyvinylidene fluoride uniformly in a mass ratio of 8:1:1, and use 1-methyl-2-pyrrolidone as a solvent to prepare negative electrode slurry material, which was coated on a copper foil to make a negative electrode sheet, and dried overnight at 50 °C. The ele...

Embodiment 3

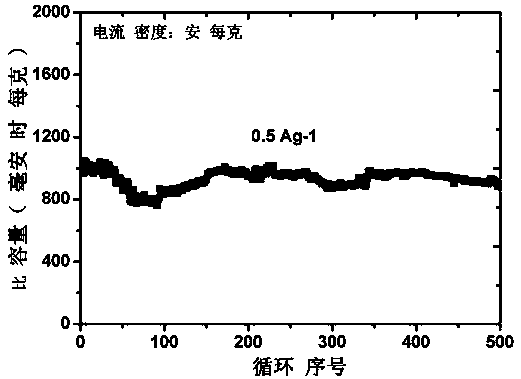

[0043] 1 g of glucose was dissolved in 20 mL of deionized water to form a solution, and then 0.2 g of tin acetate (C 4 h 6 o 4 Sn), followed by the addition of 0.8 g of diatomaceous earth (80–100 nm), glucose was used as a carbon precursor in this experiment. After that, the solution was put into a centrifuge and stirred for 10 h. After the centrifugal stirring, the solution was put into a freeze dryer to freeze for 2 h, and then dried for 8 h. The freeze-dried product was carbonized at a high temperature of 500 °C for 4 h, and after naturally falling to room temperature, the target product C-SiO was finally obtained. x -Sn. Mix the prepared tin-coated silicon oxide active material, conductive carbon black, and binder polyvinylidene fluoride uniformly in a mass ratio of 8:1:1, and use 1-methyl-2-pyrrolidone as a solvent to prepare negative electrode slurry material, which was coated on a copper foil to make a negative electrode sheet, and dried overnight at 50 °C. The ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com